Conductive agent and preparation method thereof, electrode and secondary battery

A conductive agent and electrode technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as lack of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Correspondingly, a preparation method of a conductive agent, comprising:

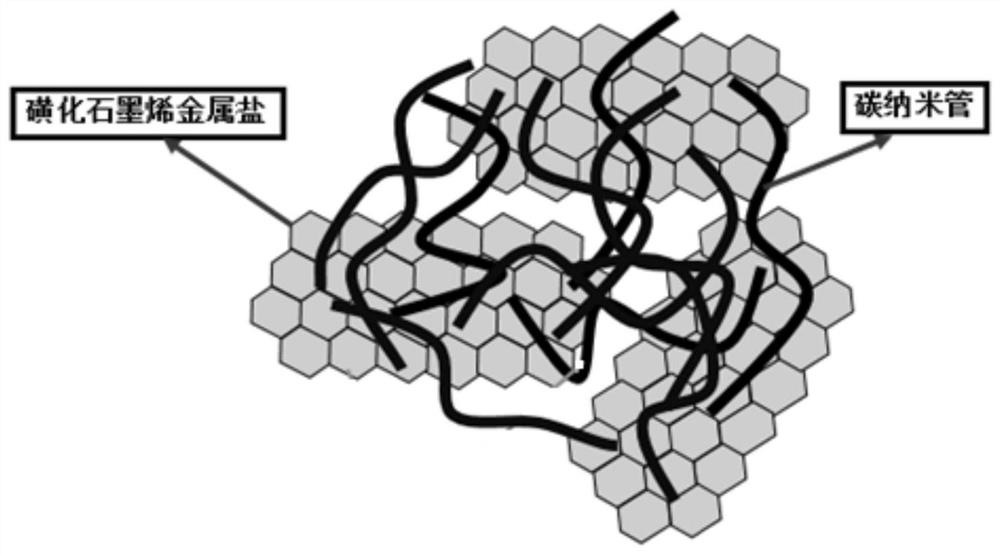

[0048] S01. Disperse the sulfonated graphene metal salt and the carbon nanotubes in a solution, so that the sulfonated graphene metal salt and the carbon nanotubes are combined to form a wire-surface conductive network.

[0049] Wherein, the type selection of the sulfonated graphene metal salt and carbon nanotubes in step S01 and the proportion of their consumption are basically the same as the above sulfonated graphene metal salts and carbon nanotubes. In order to save space, no more One more elaboration.

[0050] Specifically, the sulfonated graphene metal salt and carbon nanotubes are dispersed in a solution, so that the sulfonated graphene metal salt and carbon nanotubes are combined to form a wire-surface conductive network.

[0051] As an embodiment, the step of dispersing the sulfonated graphene metal salt and carbon nanotubes in the solution includes:

[0052] S011, mixing the sulfonate...

Embodiment 1

[0084] This embodiment provides a method for preparing a lithium ion battery, which specifically includes the following steps:

[0085] 1) Preparation of mixed powder of sulfonated graphene lithium salt and carbon nanotubes

[0086] Choose sulfonated graphene lithium salt, and the molar ratio of its sulfonate to lithium is 1:1;

[0087] Select multi-walled carbon nanotubes;

[0088] According to the mass ratio of the sulfonated graphene lithium salt and the multi-walled carbon nanotubes being 1:5, the sulfonated graphene metal salt and the multi-walled carbon nanotubes were mechanically mixed and stirred for 90 min to prepare a mixed powder.

[0089] 2) Prepare mixed solution

[0090] Under the vacuum condition of absolute pressure of 0.016MPa, according to the mass ratio of hydroxymethyl cellulose and N-methyl pyrrolidone to be 1:94, the hydroxymethyl cellulose and N-methyl pyrrolidone are heated below 70°C at a rotating speed of 1:94. 1200r / min was mixed for 60min to obta...

Embodiment 2

[0096] This embodiment provides a method for preparing a lithium ion battery, which specifically includes the following steps:

[0097] 1) Preparation of mixed powder of sulfonated graphene lithium salt and carbon nanotubes

[0098] Choose sulfonated graphene lithium salt, and the molar ratio of its sulfonate to lithium is 1:1;

[0099] Select multi-walled carbon nanotubes;

[0100] According to the ratio of the mass ratio of the sulfonated graphene lithium salt to the multi-walled carbon nanotubes is 1:6, the sulfonated graphene metal salt and the multi-walled carbon nanotubes are mechanically mixed and stirred for 90 min to prepare a mixed powder.

[0101] 2) Prepare mixed solution

[0102] Under the vacuum condition of absolute pressure of 0.016MPa, according to the mass ratio of hydroxymethyl cellulose and N-methyl pyrrolidone to be 1:94, the hydroxymethyl cellulose and N-methyl pyrrolidone are heated below 70°C at a rotating speed of 1:94. 1200r / min was mixed for 60min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com