Super capacitor

A technology of supercapacitors and internal electrodes, applied in the directions of winding capacitors, electrolytic capacitors, hybrid capacitor terminals, etc., can solve the problems of high internal resistance, high internal resistance, low energy storage density, etc., and achieve high energy density and high voltage window. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The supercapacitor provided by the present invention will be further described below in conjunction with specific embodiments and drawings.

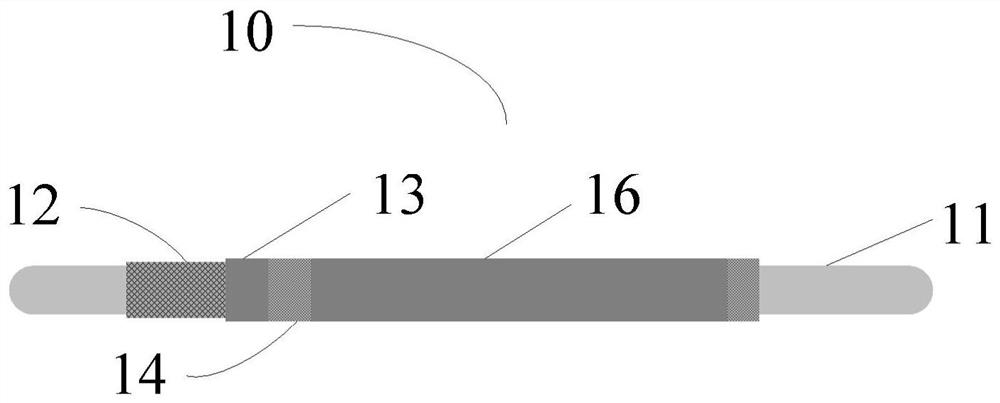

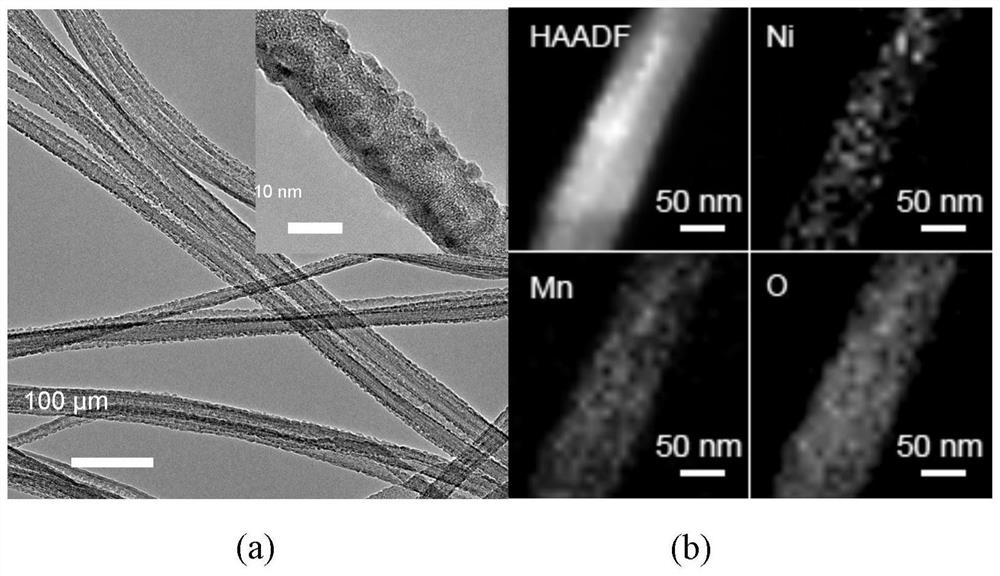

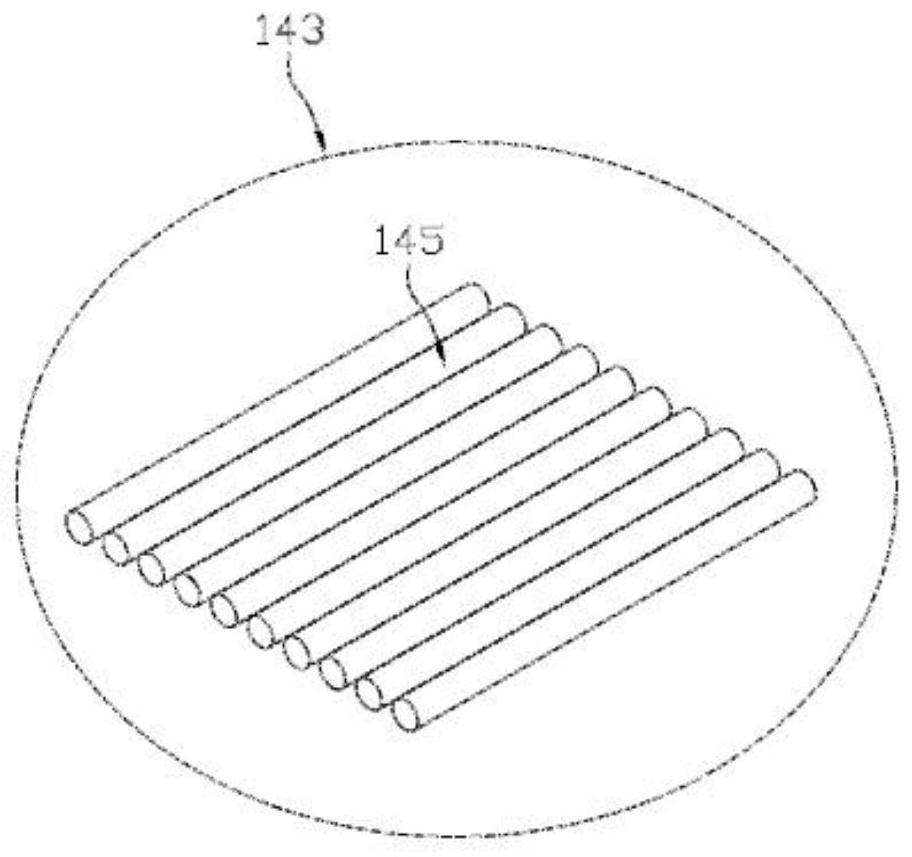

[0032] see figure 1 , The first embodiment of the present invention provides a supercapacitor 10 , including an elastic body 11 , the outer surface of the elastic body 11 wraps an inner electrode 12 , a first electrolyte layer 13 and an outer electrode 14 in sequence. The internal electrode 12 includes a carbon nanotube film and a NiO@MnO X composite structure; the external electrode 14 includes a carbon nanotube film and an Fe 2 o 3 granular layer.

[0033] The elastic body 11 is an elastic linear structure, specifically, the elastic body 11 may be an elastic cord, elastic fiber, or the like. The elongation rate of the elastic body 11 can reach 200%, and the elastic body 11 is a flexible structure, which can be bent and folded arbitrarily. In this embodiment, the elastic body 11 is an elastic fiber, and the diameter of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com