Split type crushing mechanism with rocker arm power

A crushing mechanism and split-type technology, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., can solve the problems that the conveyor cannot be conveyed, the cutting motor is occupied, and the production capacity is affected, so as to solve the power source problem and save installation space and space. Occupy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

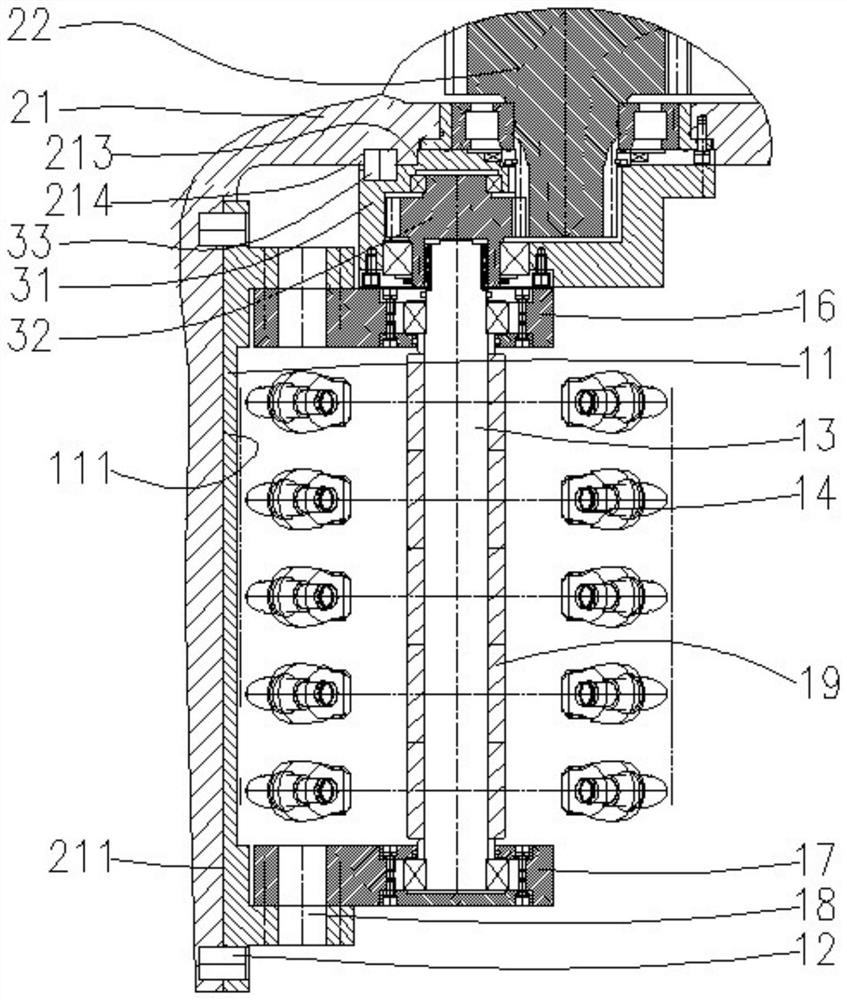

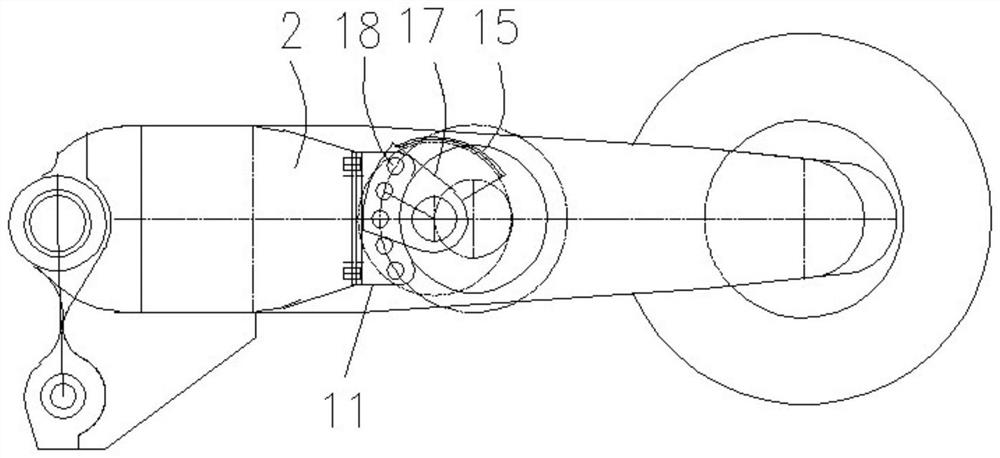

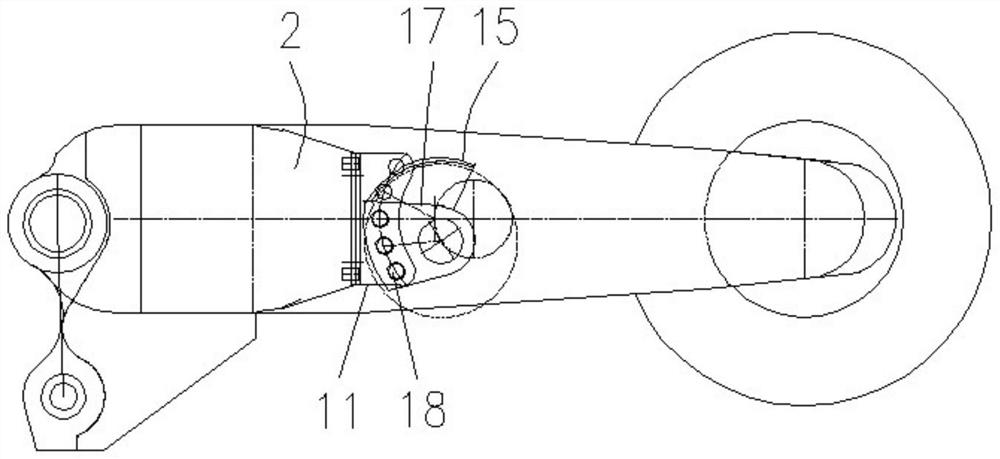

[0031] The invention discloses a split-type crushing mechanism (abbreviated as crushing mechanism) with rocker arm power, such as Figure 1-3 As shown, it includes a bracket, a connecting seat 31, a crushing tooth assembly and a rocker arm 2 of a mining machine. The support includes a base 11, a front support plate 16 and a rear support plate 17, and the base is provided with a front side plate and a rear side plate. The front and rear side panels are part of the base. The front side plate and the rear side plate are respectively provided with a plurality of side plate pin holes distributed from top to bottom. Both the front side plate and the rear side plate are symmetrical front and back, including the specification, quantity and position of the side plate pin holes thereon. The front support plate and the rear support plate are respectively provided with a plurality of support plate pin holes, and the specifications of the side plate pin holes and the support plate pin ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com