Environmental protection and energy saving device for steel structure building wall

A technology for building walls, environmental protection and energy saving, which is applied to buildings, building components, building structures, etc., can solve the problems of foam boards that cannot be disassembled and reused, not in line with environmental protection and energy saving, and destroyed, and is conducive to reuse and mitigation. Shaking and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be a clear and complete description of the technical solution in the embodiments of the present invention. Embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without doing creative labor, are within the scope of protection of the present invention.

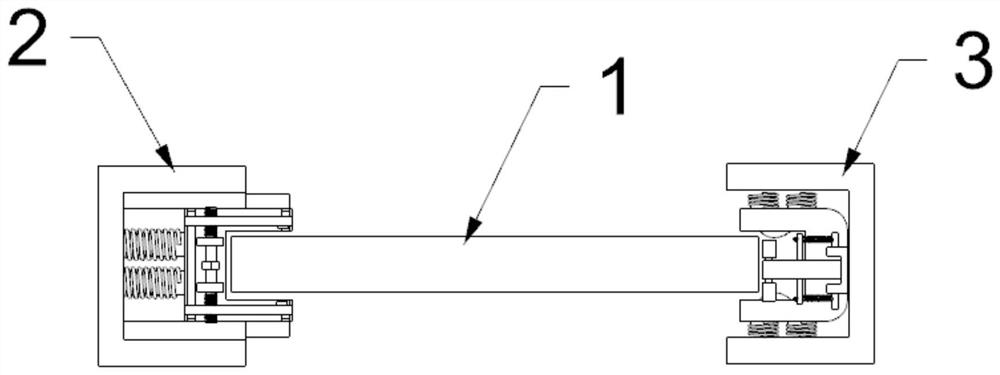

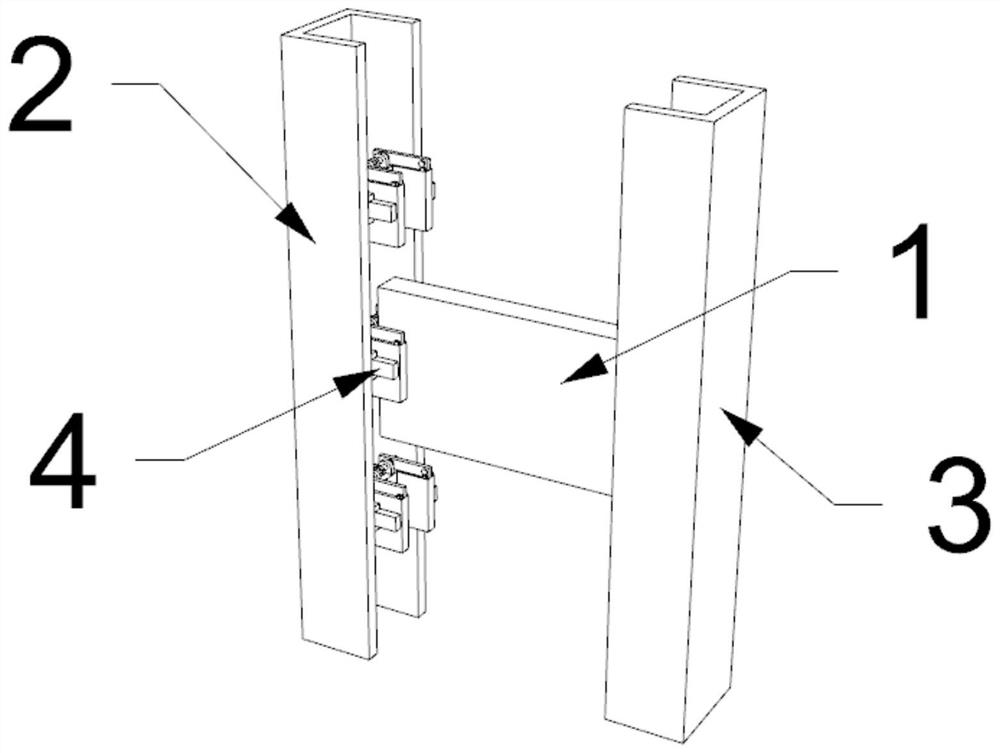

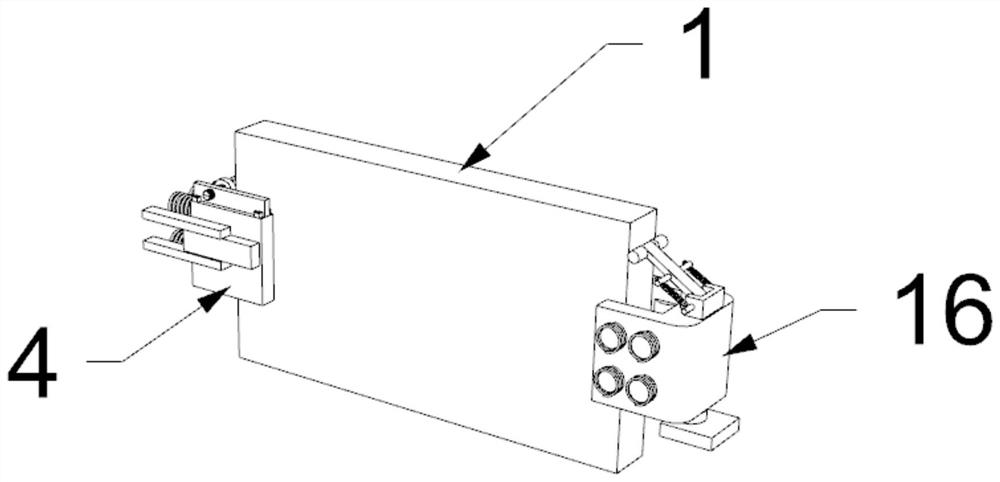

[0020] See figure see Figures 1 through 5 , the present invention provides a technical solution: a steel structure building wall environmental protection and energy-saving device, comprising a foam board 1, the first steel frame 2 and the second steel frame 3, the first steel frame 2 is provided with a mounting frame 4, the second steel frame 3 is provided with a fixing frame 16, the mounting frame 4 and the fixing frame 16 is installed with a foam plate 1, the upper surface of the mounting frame 4 is provided with a threaded rod 11, the middle of the threaded rod 11 is fixed with a first nut 12, the threaded rod 11 is mounted on the support block 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com