Yarn pressing device of flat knitting machine and working method of yarn pressing device

A technology of flat knitting machine and yarn pressing, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problem of high probability of looped floating pieces, and achieve the advantages of reducing the probability of looping floating pieces, stable operation and optimized structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0042] Example.

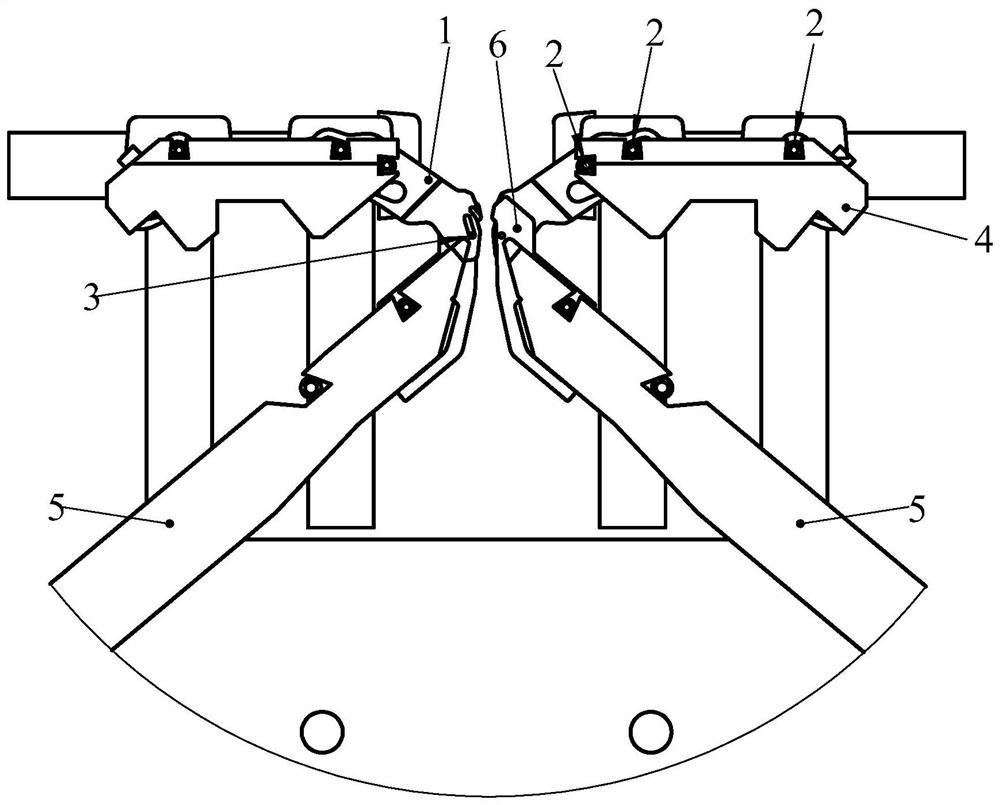

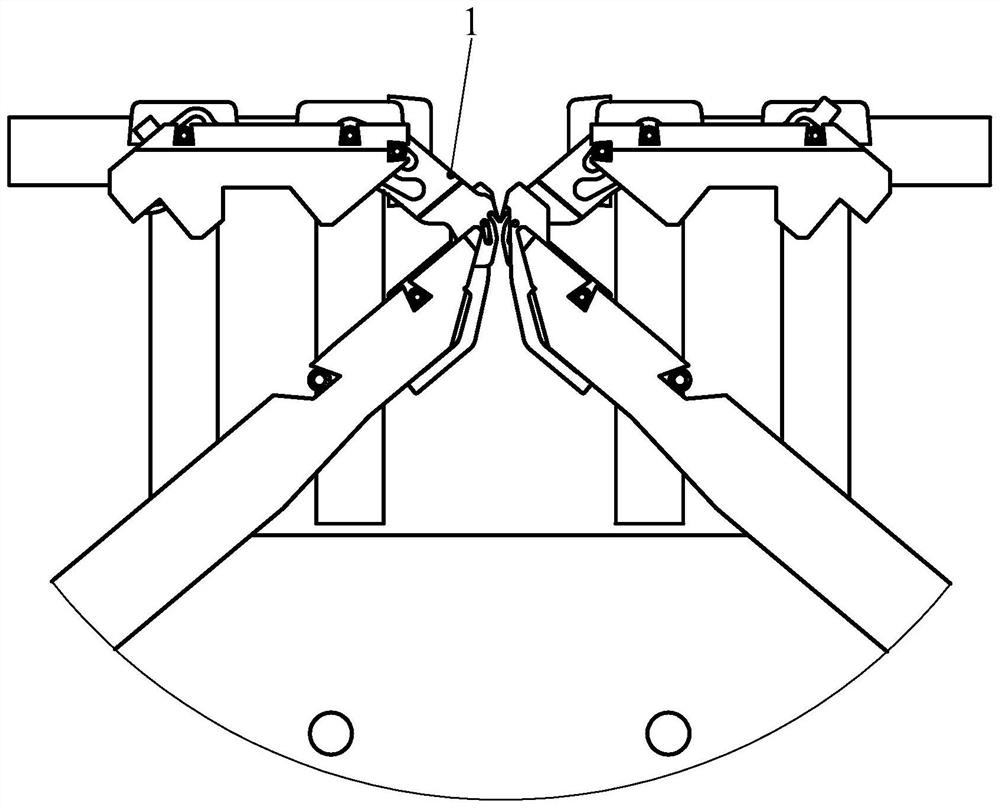

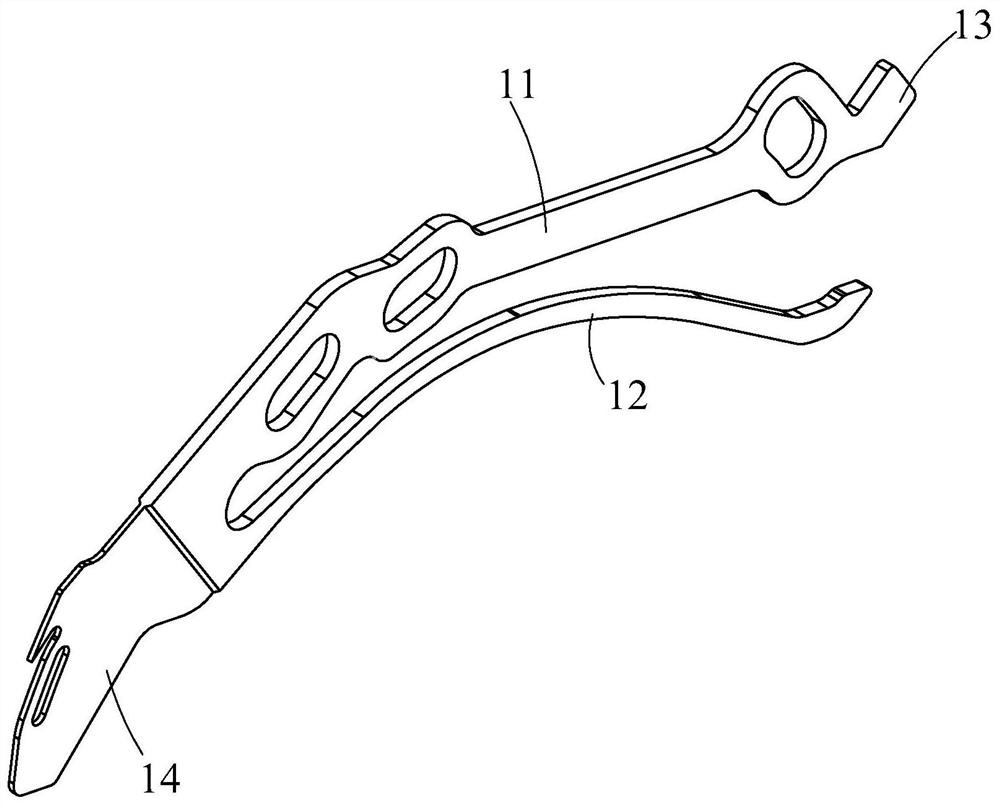

[0043] see Figure 1 to Figure 8 .

[0044] This embodiment discloses a yarn pressing device of a flat knitting machine, which includes a sinker 1 and a sinker needle plate 4 . Two sinker needle plates 4 are arranged symmetrically above the needle bed 5 of the flat knitting machine. The needle bed 5 is divided into a front needle bed and a rear needle bed. The front and rear needle beds are also symmetrically arranged front and rear. The sinker needle board 4 is arranged above the front needle bed, and the other sinker needle board 4 is arranged above the rear needle bed. Rows of knitting needles are arranged on the front and rear needle beds.

[0045] In this embodiment, the sinker needle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com