Full-automatic manufacturing and mounting machine for plastic handle of metal packaging tin

A fully automatic technology for metal packaging cans, which is applied in the field of production equipment for metal packaging cans, can solve the problems affecting the high-efficiency production and wide application of plastic handles, the structure of production equipment is not specific and perfect, etc., and achieves perfect functional structure settings, The effect of high quality work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

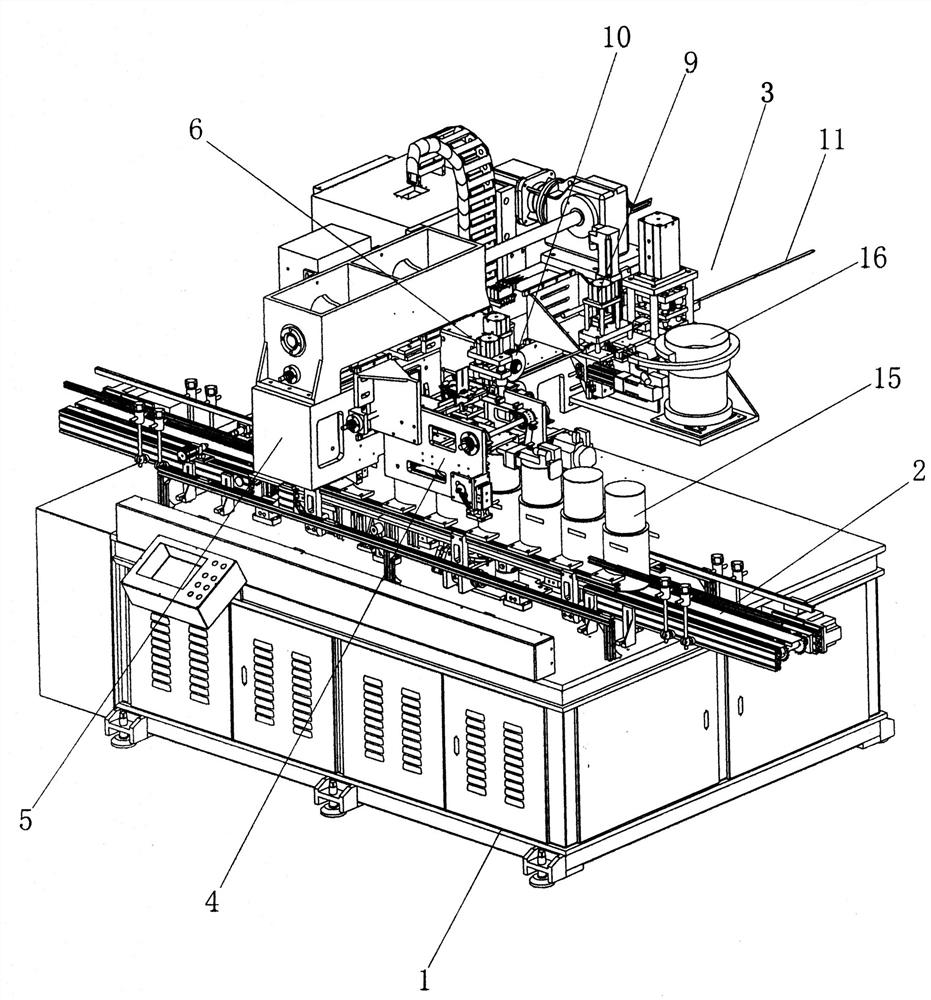

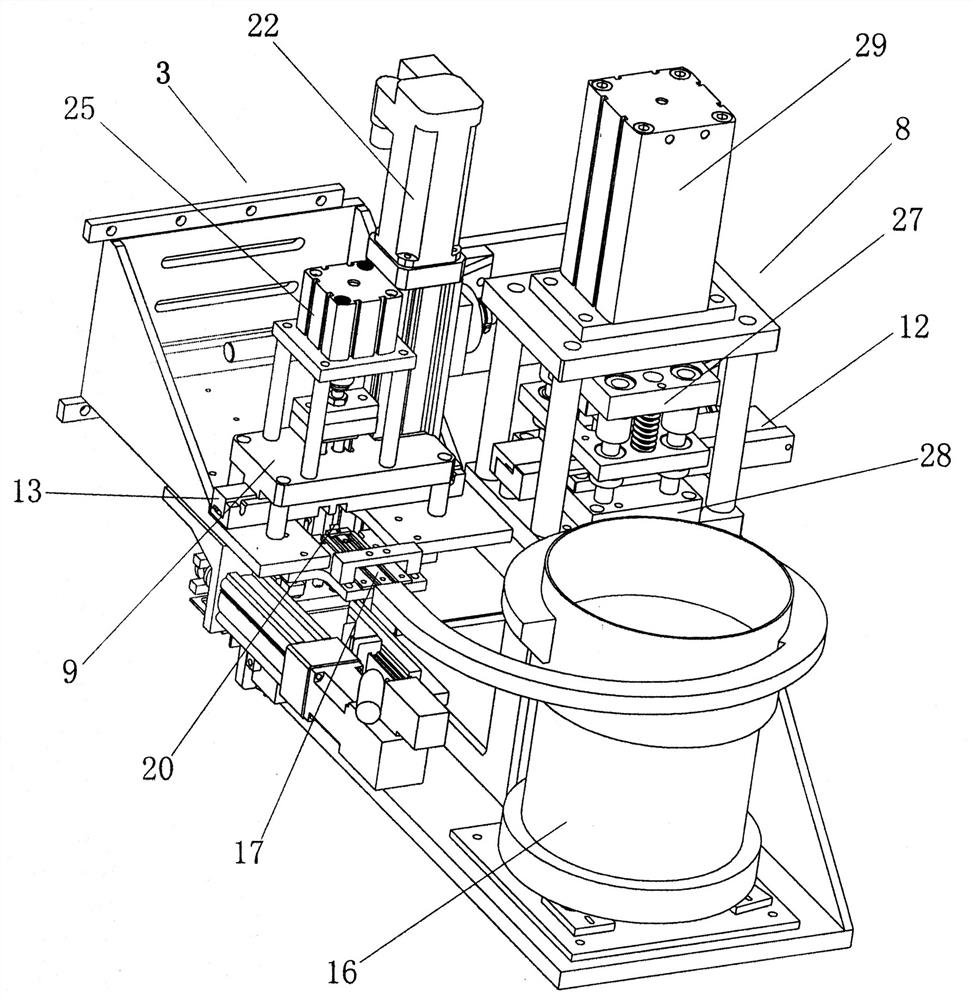

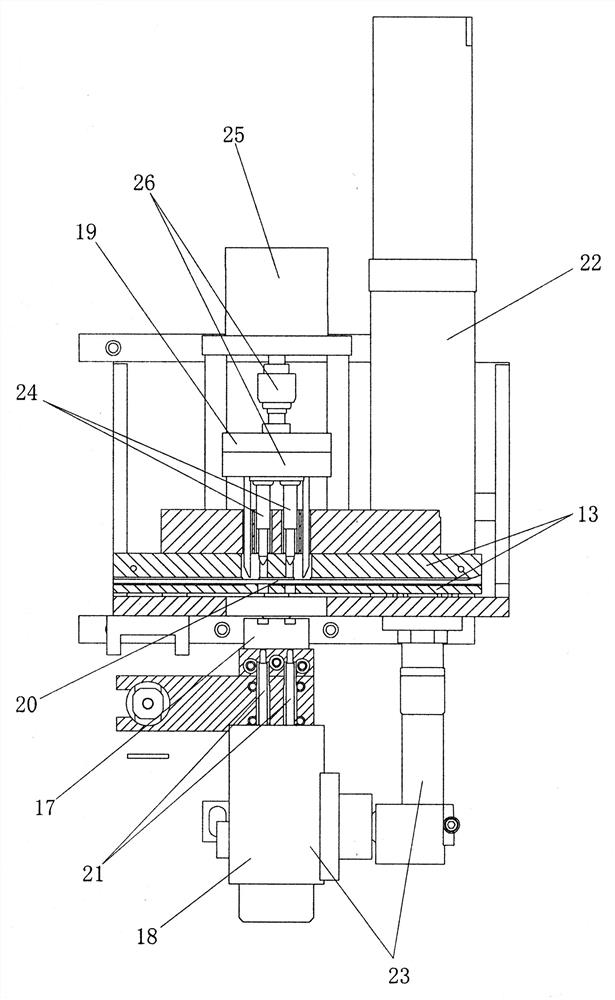

[0022] refer to Figure 1 to Figure 5, the automatic production and installation machine for the plastic handle of the metal packaging can, including the frame 1 and the metal packaging can body conveying mechanism 2 installed on the frame 1, the plastic handle making mechanism 3, the plastic handle forwarding mechanism 4 and the welding Nail welding mechanism 5, wherein the metal packaging can body conveying mechanism 2 is arranged vertically, the plastic handle making mechanism 3 is arranged horizontally, and the plastic handle forwarding mechanism 4 is located between the metal packaging can body conveying mechanism 2 and At the intersection of the plastic handle making mechanism 3, the welding stud welding mechanism 5 is located in front of the plastic handle forwarding mechanism 4 above the metal packaging can body conveying mechanism 2, and the feature is: the front of the plastic handle The delivery mechanism 4 includes a plastic handle cutting mechanism 6, a plastic ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com