Automatic processing machine for carbon corrugated pipe

A bellows and processing machine technology, applied in metal processing and other directions, can solve the problems of small use range, adjustment, poor versatility, etc., and achieve the effect of improving the effect of restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

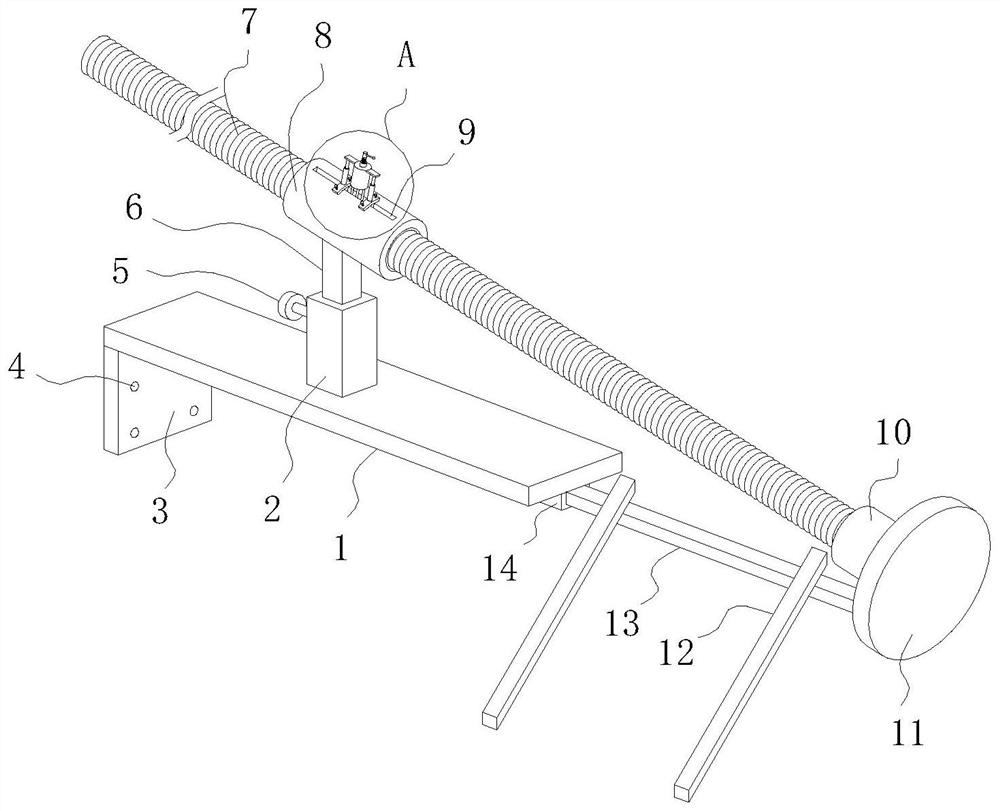

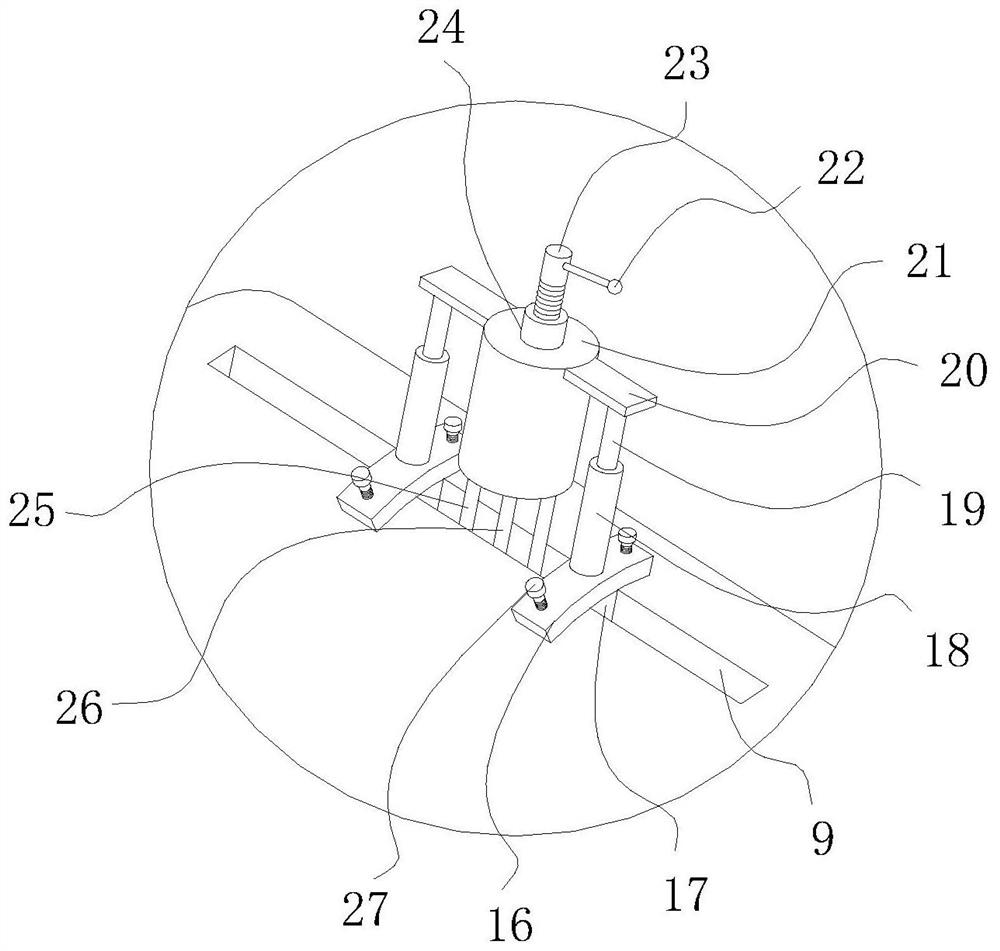

[0039] Specific implementation method: When the cutting length of the bellows 7 is determined, the position of the upper arc-shaped plate 16 is adjusted along the strip groove 9, and then the upper arc-shaped plate 16 drives the lower arc-shaped plate 35 to slide through the slide plate 17, when the limit When the component can be stuck between the two adjacent expansion rings of the bellows 7, the position of the upper arc plate 16 is fixed by the clamping bolt 27, and the position of the liquid storage cylinder 21 changes accordingly, realizing convenient adjustment of the limit component The relative position with bellows 7.

[0040] Insert the two inserting rods 19 on the liquid storage cylinder 21 into the two sleeves 18 respectively, and then under the action of the mutual attraction of the fixed magnet 36 and the movable magnet 37, it is realized that the limit assembly is placed adjacent to the bellows 7 Between the two expansion rings, on the contrary, it is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com