Tin scraping device

A technology of tin scraping and scraping, which is applied in the field of tin scraping devices, which can solve problems such as damage to the scraper, burns, splashing of tin liquid, etc., and achieve the effect of avoiding safety accidents and smooth scraping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

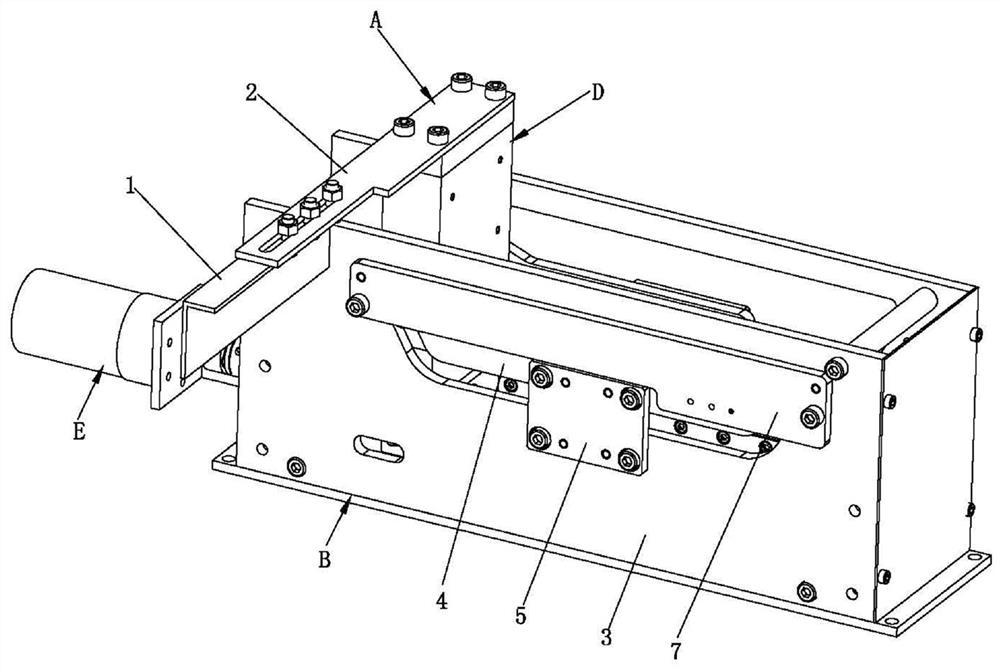

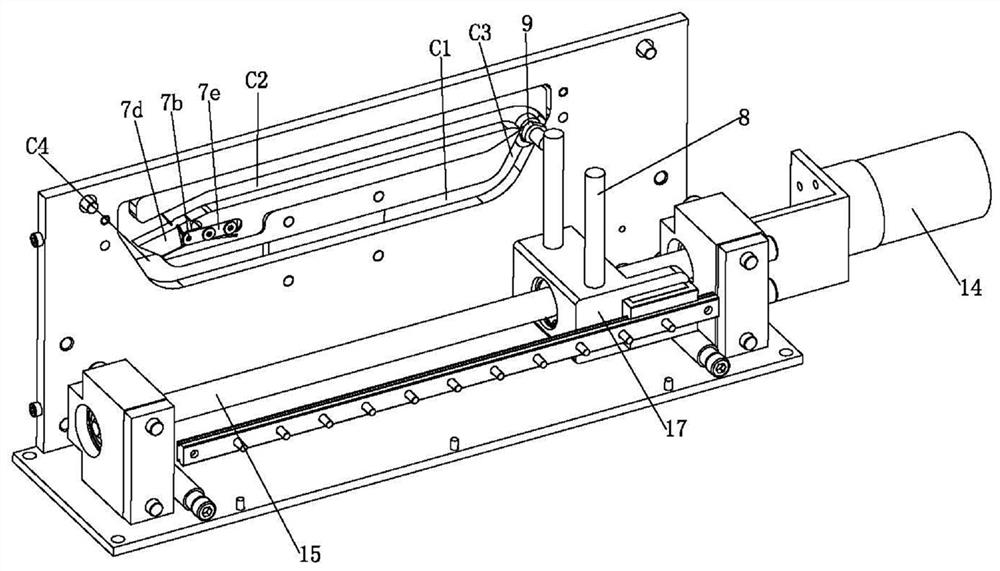

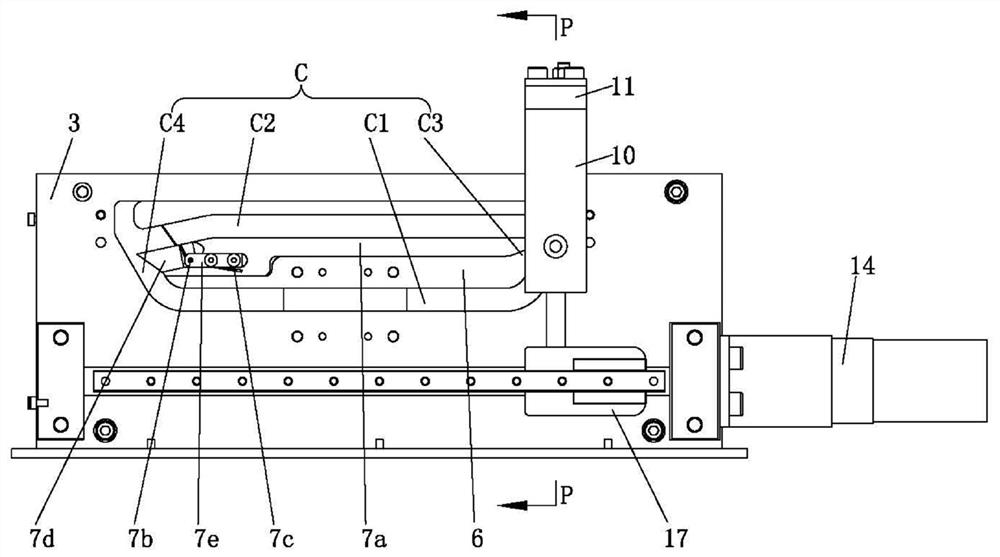

[0026] Combine below Figure 1 to Figure 6 The present invention will be described.

[0027] Such as Figure 1 to Figure 6 The tin scraping device of the present invention includes a scraper assembly A, a bracket B, a lifting assembly D, and a reciprocating drive mechanism E. An annular groove C is provided on the side wall of the bracket B, and the lifting assembly D cooperates with the annular groove C. The scraper assembly A is connected to the lifting assembly D, the reciprocating drive mechanism E drives the lifting assembly D to reciprocate along the annular groove C, and the lifting assembly D is connected to the reciprocating drive mechanism E. The reciprocating drive mechanism E drives the lifting component D to move linearly. Since the lifting component D cooperates with the annular groove C, when the lifting component D is moving in a straight line, according to the contour path of the circular groove C, it will also perform a downward or upward movement in some pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com