Self-adaptive universal stacking table

A stacking platform and self-adaptive technology, which is applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of short production cycle, bumped workpieces, labor and time-consuming, etc., and achieves simple structure and low cost. Low cost and high position control accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0037] 1. Stacking platform

[0038] 1. The overall structure of the stacking platform

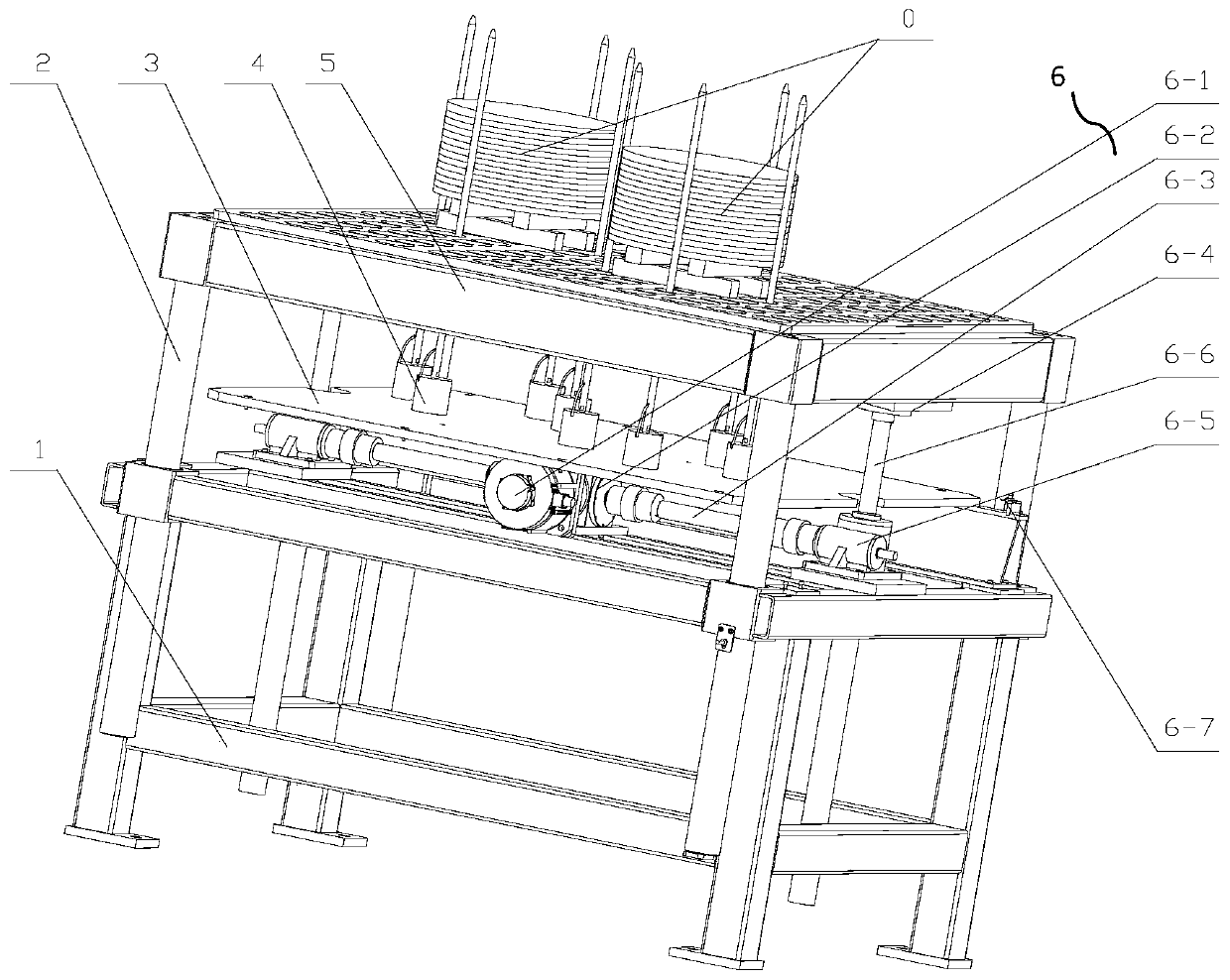

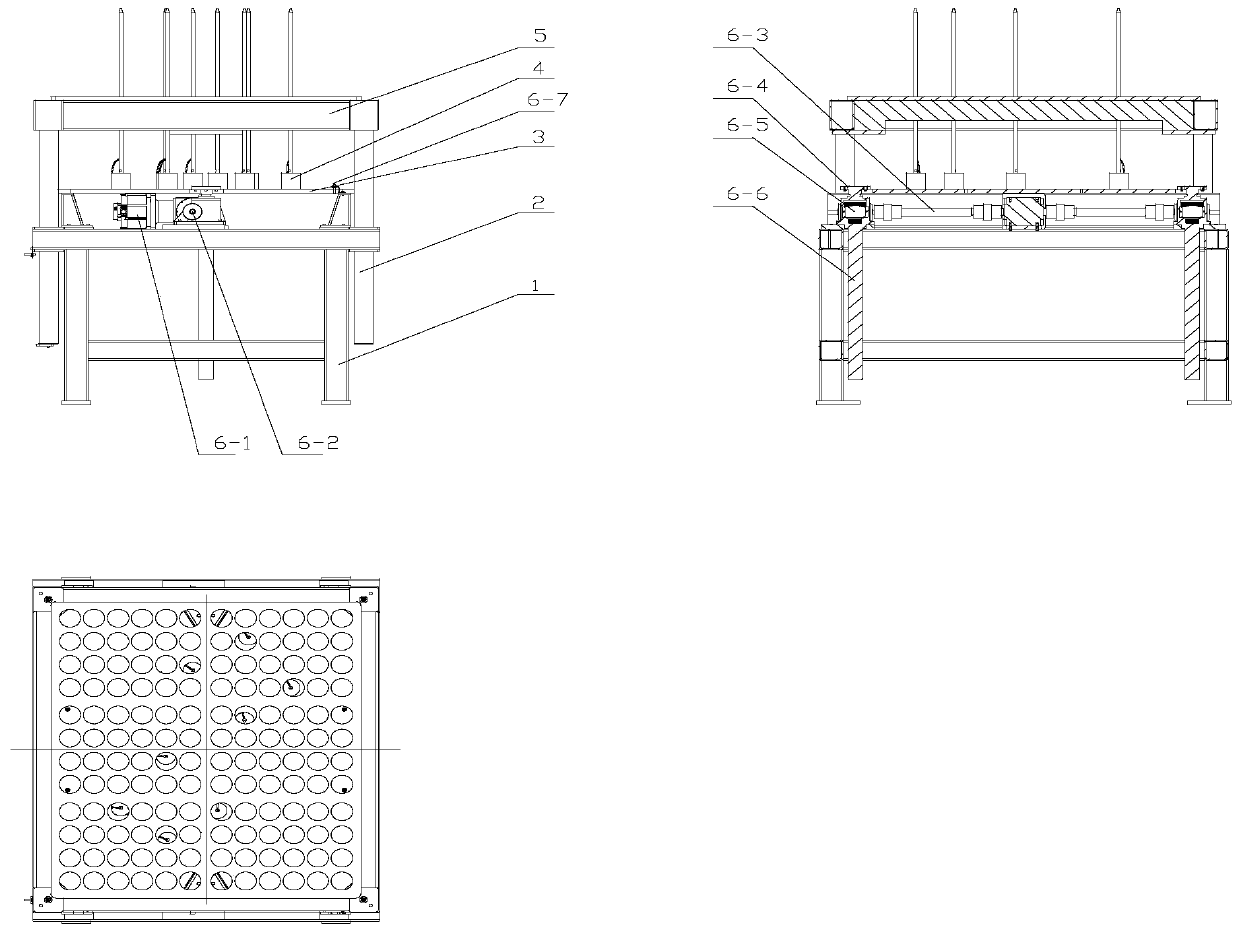

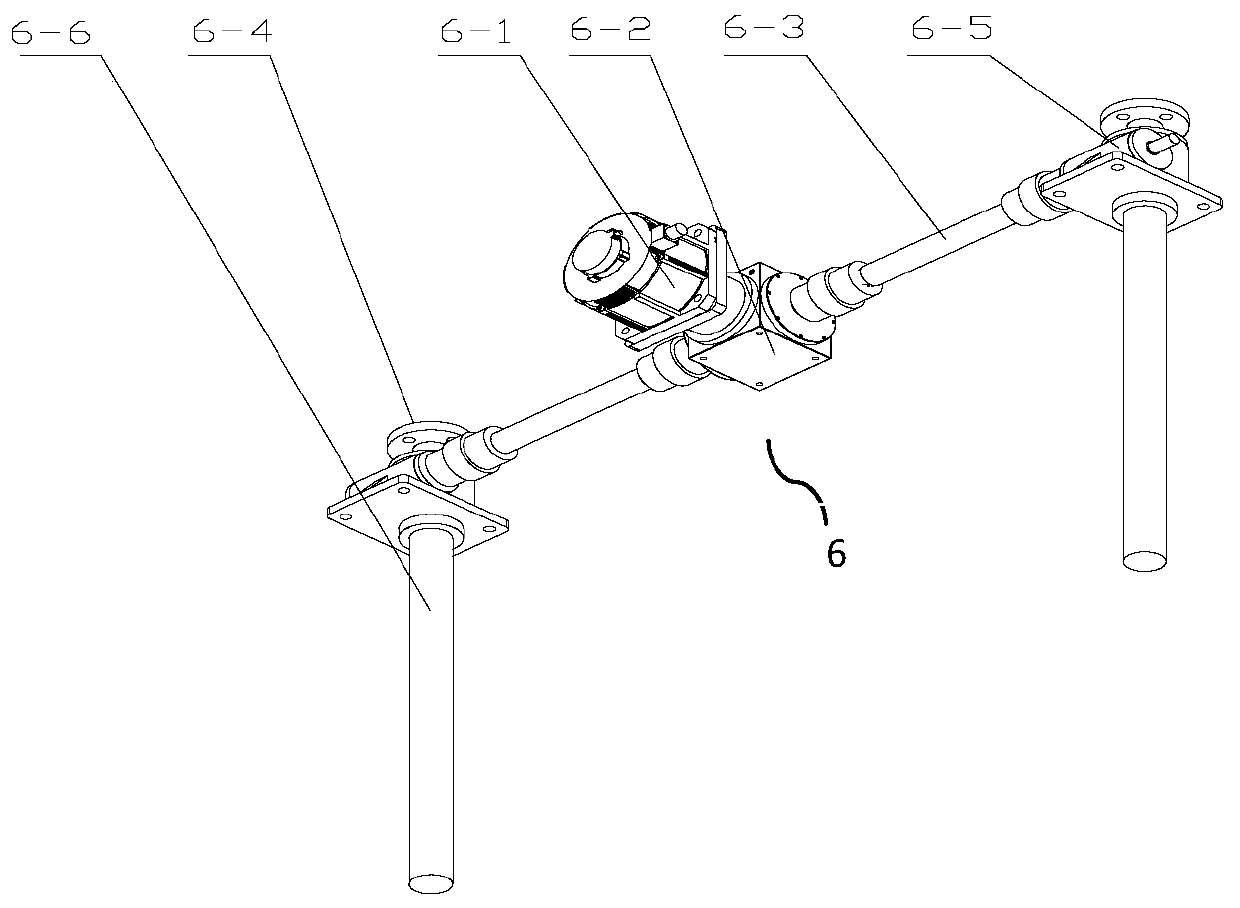

[0039] Such as figure 1 , 2 , the present invention includes a base 1, a guide post 2, an intermediate tray 3, a magnetic guide rod 4, a movable stacking tray 5 and a drive lifting mechanism 6;

[0040] Its location and connection relationship are:

[0041] From bottom to top, base 1, guide column 2 and movable stacking tray 5 are connected in sequence;

[0042] On the top surface of the base 1, from bottom to top, there are sequentially provided with a driving lifting mechanism 6, an intermediate tray 3 and a magnetic guide rod 4, and the magnetic guide rod 4 passes through the round hole of the movable stacking pallet 5, and is clamped and placed Workpiece 0 on movable stacking pallet 5 .

[0043] Working mechanism:

[0044] The stacking table is divided into upper and lower parts, of which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com