Coal gangue hill fire extinguishment and reburning prevention method using coal-based solid waste

A coal gangue and coal-based technology, applied in fire rescue, medical science, dentistry, etc., can solve problems affecting work, achieve the effects of saving consumption, realizing comprehensive management, and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

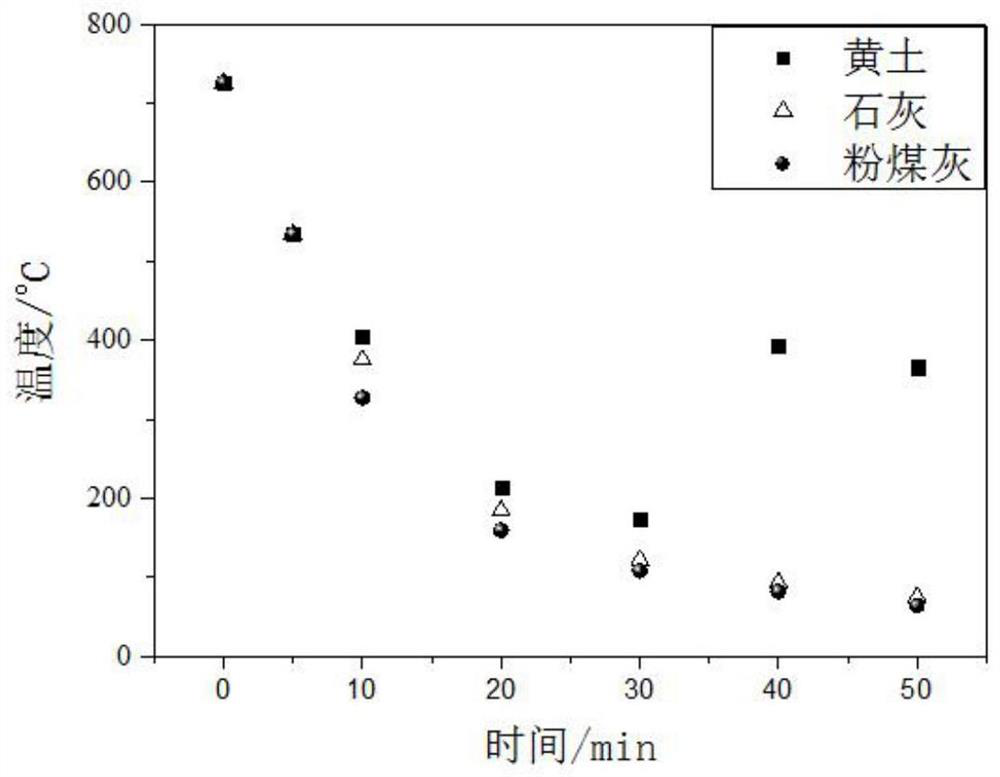

[0029] Example 1 Comparison of solid waste-based fire extinguishing slurry with loess slurry and lime slurry

[0030] Solid waste-based fire extinguishing slurry: put 280g of fly ash, 80g of lime, 40g of cement, 2.4g of water glass, and 280g of water into a container, stir with a stirrer for 15 minutes, and mix well to obtain the fire extinguishing slurry. Measure its 2h water separation rate 2.47%,

[0031] Loess fire extinguishing slurry: 70g of loess, 30g of cement, and 80g of water, the rate of water separation in 2 hours is 2.7%.

[0032] Lime fire extinguishing slurry: 70g of lime, 30g of cement, and 110g of water. The rate of water precipitation in 2 hours is 1.2%.

[0033] In a cylindrical iron drum with a diameter of 15cm and a height of 30cm, quickly put the coal gangue block layer, the ignited carbon block layer, and the coal gangue block layer from bottom to top, each layer is about 8cm thick, and the coal gangue block and The particle size of the carbon block is...

Embodiment 2

[0034] Embodiment 2 solid waste base gel sealing material

[0035] Mix 70 kg of circulating fluidized bed boiler fly ash, 20 kg of circulating fluidized bed boiler fly ash with a particle size of 5-10 μm, and 10 kg of slag Portland cement marked 32.5, add 22 kg of water and continue stirring evenly to obtain Fly ash based cementitious material. After curing, the 1-day compressive strength was 3.8 MPa, the 3-day compressive strength was 8.5 MPa, and the 7-day compressive strength was 21.6 MPa as measured by a mechanical strength tester.

Embodiment 3

[0036] Embodiment 3 solid waste base gel sealing material

[0037]Mix 80 kg of circulating fluidized bed boiler fly ash, 10 kg of circulating fluidized bed boiler fly ash with a particle size of 5-10 μm, and 10 kg of ordinary Portland cement labeled 32.5, add 25 kg of water and continue stirring evenly to obtain Fly ash based cementitious material. After curing, the 1-day compressive strength was 3.4MPa, the 3-day compressive strength was 8.3MPa, and the 7-day compressive strength was 20.3MPa as measured by a mechanical strength tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com