A kind of betel nut extract for improving gastric motility and its preparation process and application

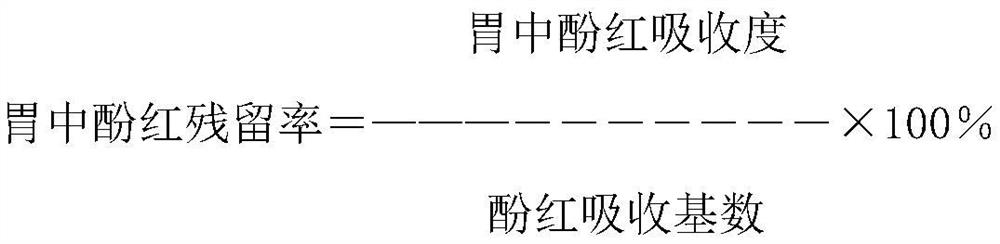

A preparation process and extract technology, applied in betel nut extract and its preparation process and application field, can solve the problems of poor transfer rate of active ingredients, affecting drug safety, affecting drug activity, etc., to reduce the residual rate of phenol red, Good gastric emptying effect, enhanced activity and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

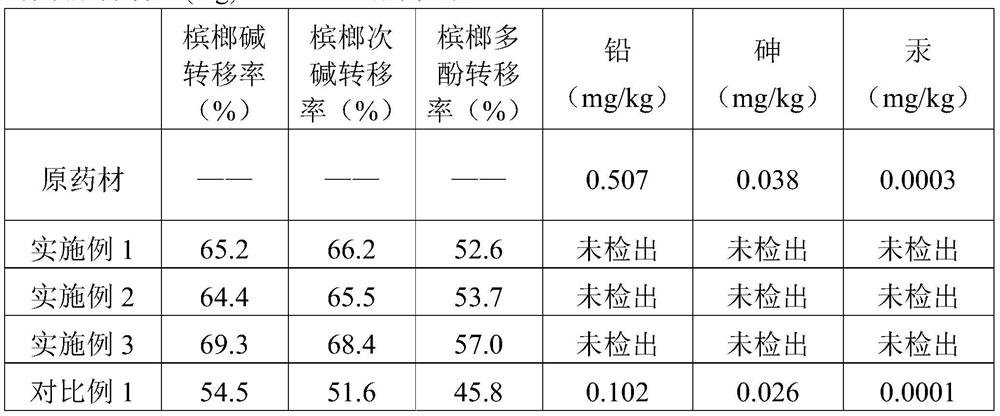

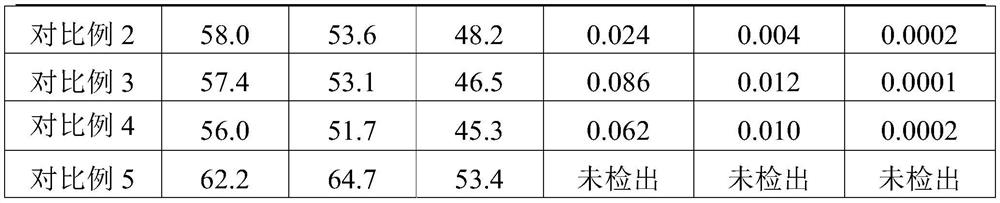

Examples

Embodiment 1

[0022] The preparation of embodiment 1-betel nut extract

[0023] Take the fried betel nut Chinese medicinal material and crush it, use ether, ethanol, and chloroform as the extraction solvent in a volume ratio of 1:0.2:0.03, the mass volume ratio of the crushed betel nut to the extraction solvent kg / L is 1:8, and then add the Carbonate buffer solution, the volume ratio of the extraction solvent to the carbonate buffer solution is 100:5, shake and extract at 140rpm for 40 minutes, then heat and reflux for 20 minutes, collect the extract, repeat the reflux extraction 3 times, and combine The total extract is added with a composite adsorbent, the mass volume ratio of the composite adsorbent to the total extract kg / L is 1:10, and the composite adsorbent is composed of chitosan, diatomaceous earth and 1. Prepared by activated carbon, let it stand for 15 minutes; filter, concentrate the filtrate under reduced pressure at 60-70°C to form a thick paste, and dry it to obtain it.

Embodiment 2

[0024] The preparation of embodiment 2-betel nut extract

[0025] Take the fried betel nut Chinese medicinal material and crush it, use ether, ethanol, and chloroform as the extraction solvent in a volume ratio of 1:0.3:0.05, the mass volume ratio kg / L of the betel nut to the extraction solvent after crushing is 1:12, and then add Carbonate buffer solution, the volume ratio of the extraction solvent to the carbonate buffer solution is 100:7, shake and extract at 160rpm for 20 minutes, then heat and reflux for 40 minutes, collect the extract, repeat the reflux extraction 3 times, and combine The total extract is added with a composite adsorbent, the mass volume ratio of the composite adsorbent to the total extract kg / L is 1:12, and the composite adsorbent is composed of chitosan, diatomaceous earth and , prepared by activated carbon, let it stand for 20 minutes; filter, concentrate the filtrate under reduced pressure at 60-70°C to form a thick paste, and dry it to obtain it.

Embodiment 3

[0026] The preparation of embodiment 3-betel nut extract

[0027] Take the fried betel nut Chinese medicinal material and crush it, use ether, ethanol, and chloroform as the extraction solvent in a volume ratio of 1:0.28:0.04, and the mass volume ratio kg / L of the betel nut to the extraction solvent after crushing is 1:10, and then add Carbonate buffer solution, the volume ratio of the extraction solvent to the carbonate buffer solution is 100:6, shake and extract at 150rpm for 30 minutes, then heat and reflux for 30 minutes, collect the extract, repeat the reflux extraction 3 times, and combine The total extract is added with a composite adsorbent, the mass volume ratio of the composite adsorbent to the total extract kg / L is 1:10, and the composite adsorbent is composed of chitosan and diatomite with a mass ratio of 1:0.07:0.15 1. Prepared by activated carbon, let it stand for 18 minutes; filter, concentrate the filtrate under reduced pressure at 60-70°C to form a thick paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com