Display panel and preparation method thereof

A display panel and display layer technology, applied in radiation control devices, optics, instruments, etc., can solve the problem of overall thickness of the display panel, achieve the effect of reducing thickness and improving market applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

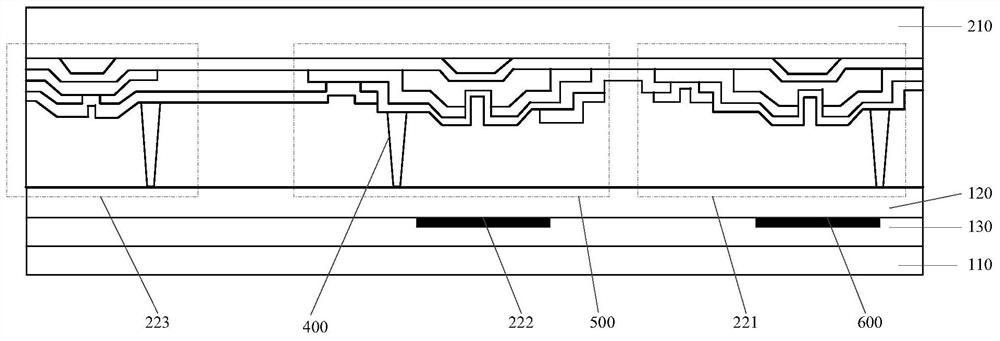

[0037] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0038] The following description is given to enable any person skilled in the art to make and use the application. In the following description, details are set forth for purposes of explanation. It should be understood that one of ordinary skill in the art would recognize that the present application may be practiced without these specific details. In other instances, well-known structures and processes are not described in detail to avoid obscuring the description of the present application with unnecessary detail. Thus, the present application is not intended to be limited to the embodiments shown, but is to be accorded the widest scope consistent with the principles and features disclosed in this application.

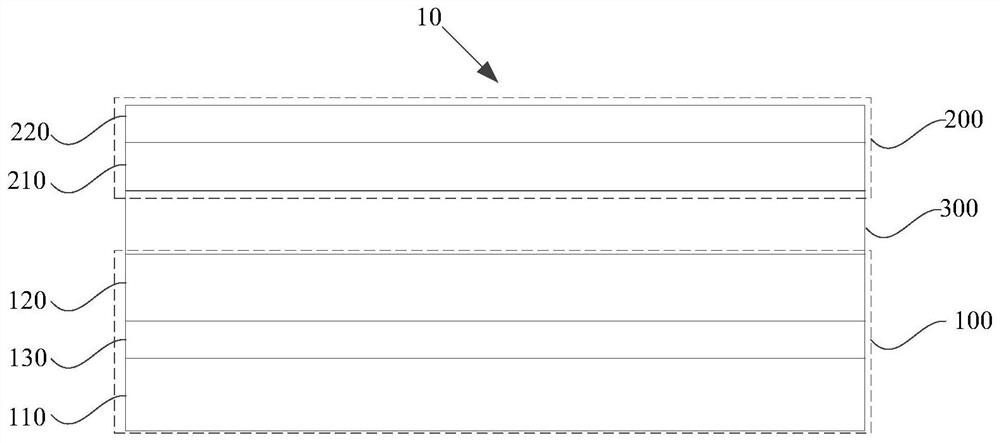

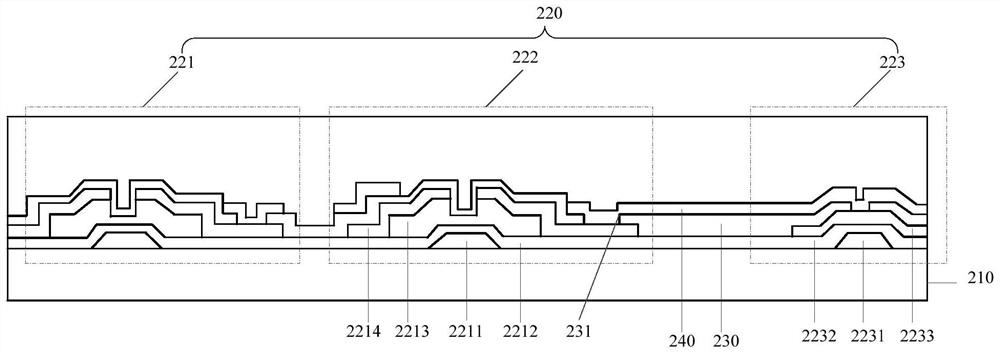

[0039] Embodiments of the present application provide a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com