Novel environment-friendly process for producing lithium carbonate

A lithium carbonate, environment-friendly technology, applied in lithium carbonate;/acid carbonate, mixer with rotary stirring device, dissolving and other directions, can solve the problems of environmental protection, low utilization rate of raw materials, etc. Mixing effect, reducing the risk of dust emissions, increasing the effect of the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing, but protection scope of the present invention is not limited to the following description.

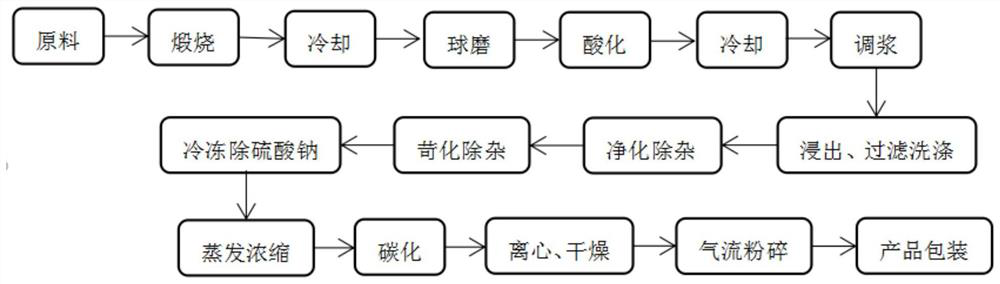

[0054] A kind of technology of novel environment-friendly production lithium carbonate, comprises the following steps:

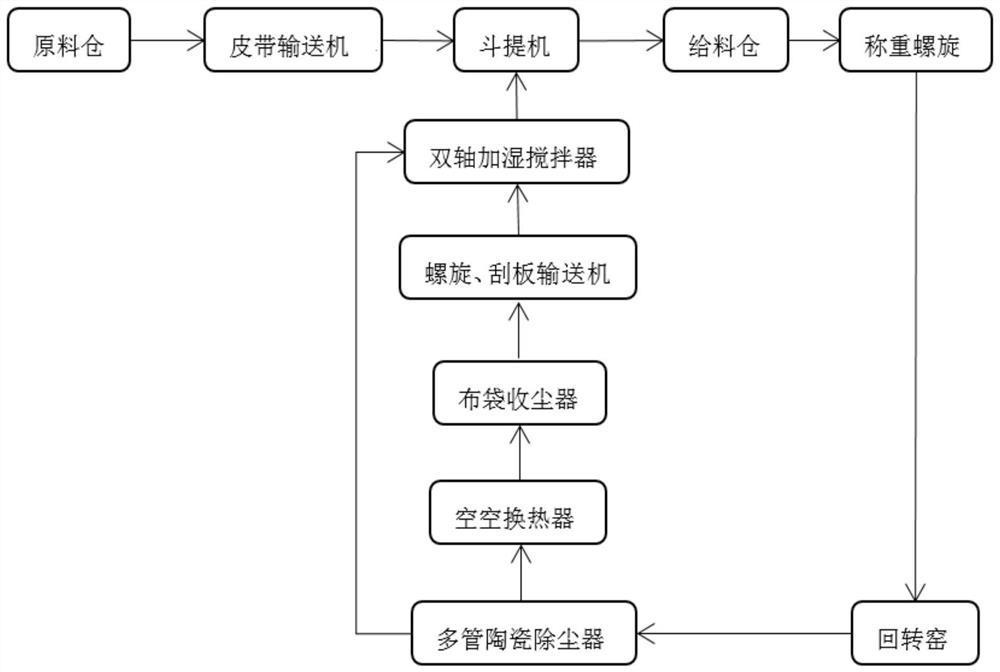

[0055] S1. Transform the spodumene through rotary kiln calcination. The calcination temperature is 950-1200°C. The smoke generated during the calcination process passes through the tail gas treatment system, and the dust is recycled to the twin-shaft humidification mixer for humidification treatment, and then added to the rotary kiln for calcination. ; After cooling, fine grinding, acid reaction, and cooling in sequence, the product to be reacted with acid is cooled to ≤90°C and then made into a slurry with water, and the solid content of the slurry is 10% to 70%;

[0056] S2. Add calcium carbonate slurry to the slurry obtained in step S1 and stir for leaching. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com