Capping device for oil drum in workshop

A technology for oil drums and equipment, which is applied in the field of oil drum capping equipment for workshops, can solve the problems of low capping efficiency, long time-consuming capping, and large energy consumption, so as to reduce trouble, reduce physical strength, and reduce burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

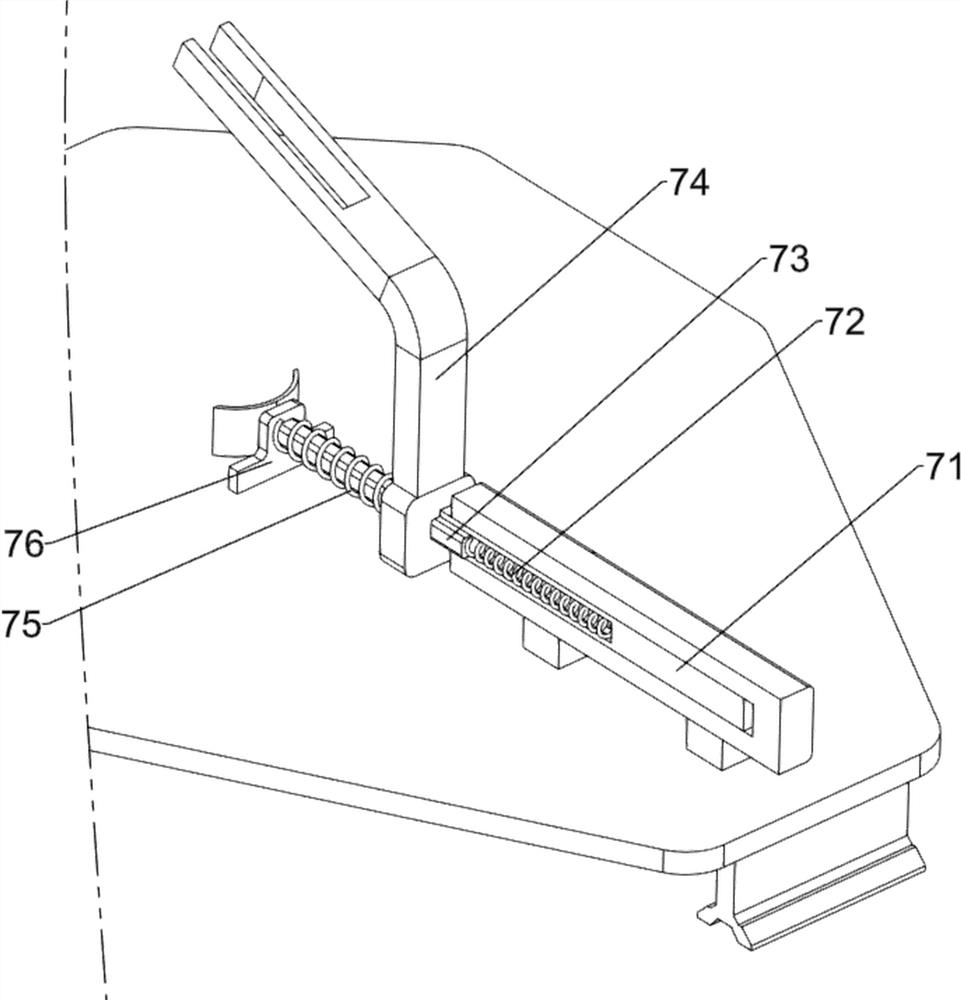

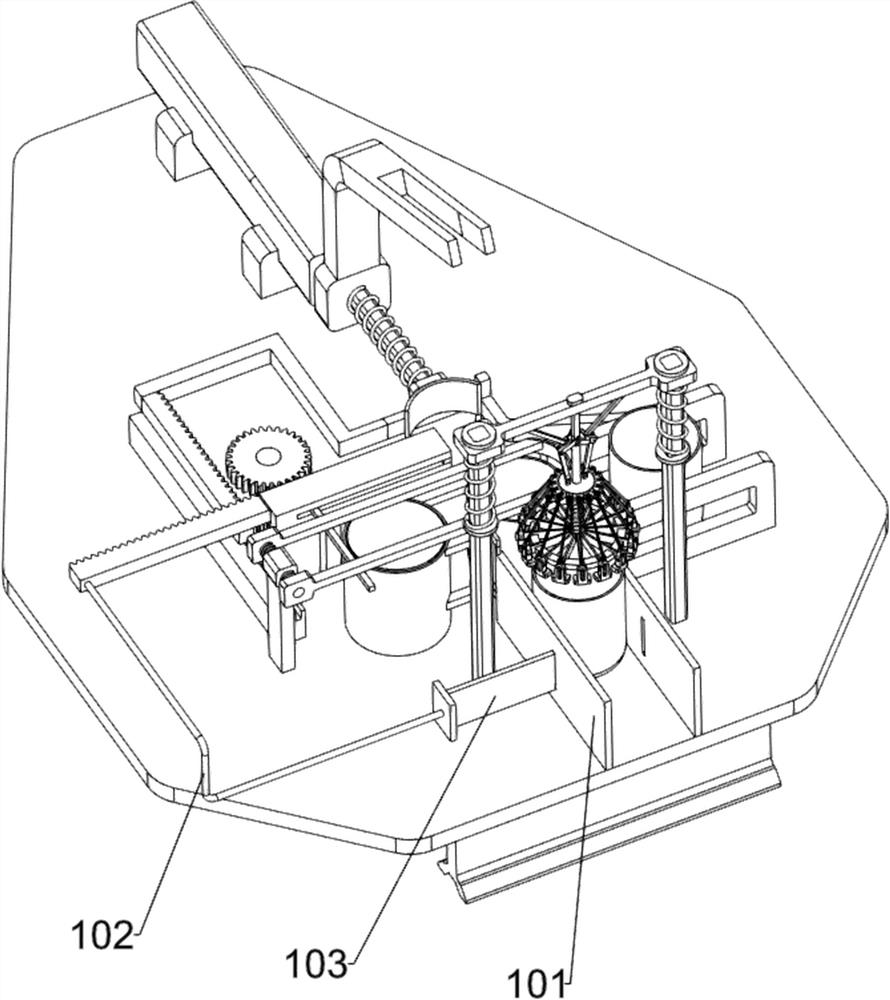

[0031] A workshop oil drum capping equipment, such as figure 1 and figure 2 As shown, it includes a base 1, a support block 2, a pressing mechanism 3 and an edge banding mechanism 4. The front side of the base 1 is fixed with two front and rear support blocks 2 by screws, and a pressing mechanism 3 is provided on the rear upper side of the base 1. , The pressing mechanism 3 is provided with an edge banding mechanism 4 .

[0032] When the oil barrel needs to be sealed, the oil barrel cover is placed on the oil barrel, and then the oil barrel is moved to the pressing mechanism 3 times, and then the edge sealing mechanism 4 is controlled, and the edge sealing mechanism 4 will seal the oil barrel After the oil barrel is capped, the edge banding mechanism 4 is no longer controlled, and the pressing mechanism 3 will drive the edge banding mechanism 4 to automatically reset, then remove the capped oil barrel, and then repeat the above operations.

[0033] The pressing mechanism 3 ...

Embodiment 2

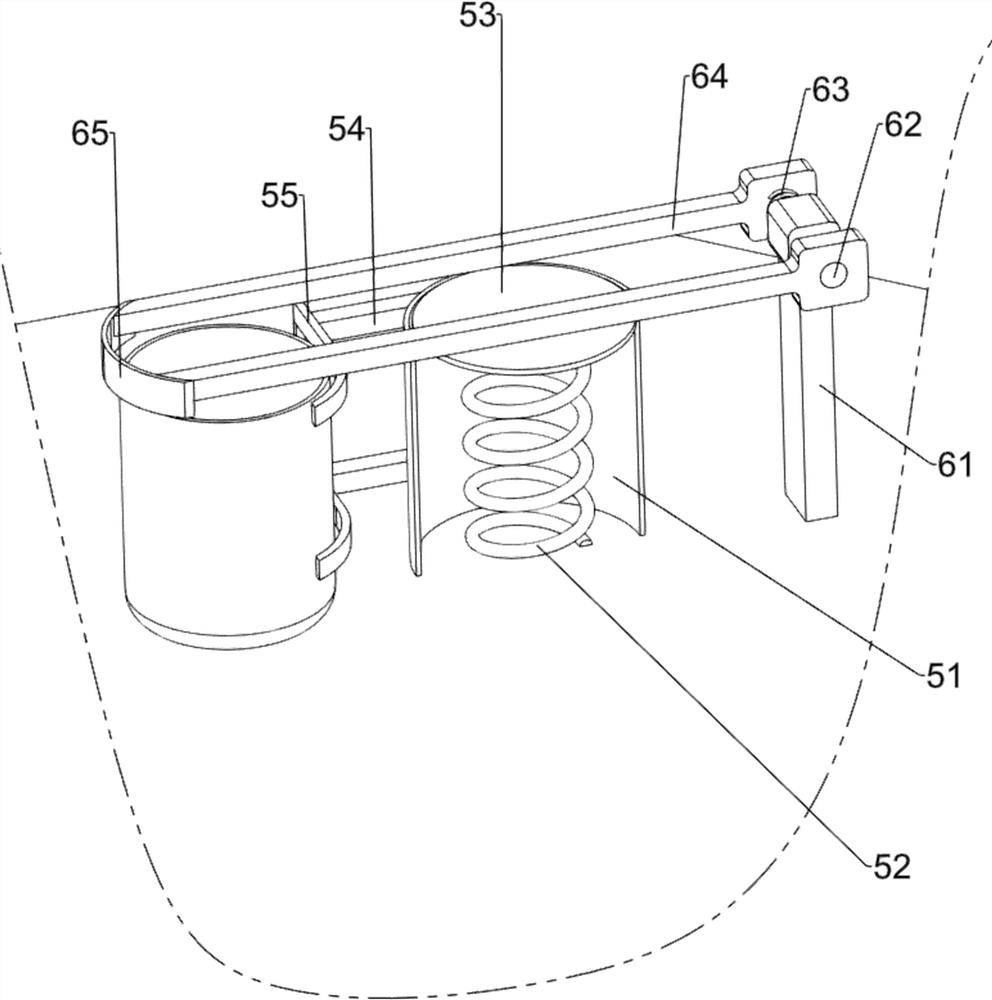

[0038] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a bung storage mechanism 5 is also included, and the bung storage mechanism 5 includes a discharge barrel 51, a third spring 52, a placement plate 53, a third connecting rod 54 and a first stop 55, and the upper side of the base 1 A discharge barrel 51 is provided, the bottom in the discharge barrel 51 is connected with a third spring 52, and the upper side of the third spring 52 is connected with a placement plate 53, and the placement plate 53 cooperates with the discharge barrel 51, and the left side of the discharge barrel 51 A third connecting rod 54 is connected to the front and rear sides of the front part, and a first block 55 is connected between the left side of the third connecting rod 54 .

[0039] When the oil barrel needs to be sealed, the oil barrel lid is placed on the placement plate 53, and the third spring 52 will be deformed. When a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com