Optical film continuous automatic film covering device and working method

A coating device and optical membrane technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of inability to eliminate wrinkles and sundries, high product defective rate, low coating efficiency, etc. , to achieve the effects of easy manufacture and use, high lamination efficiency and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

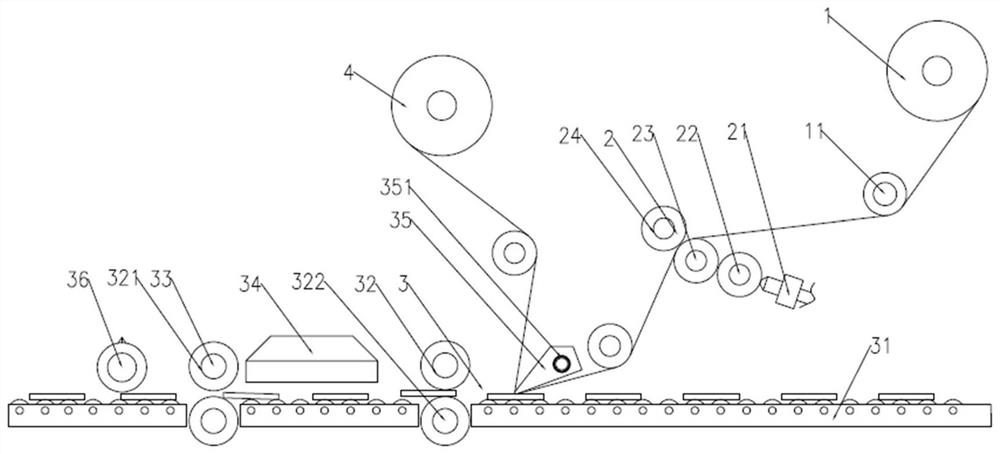

[0020]Such asfigure 1An optical film continuous automatic coating apparatus and a working method, including the discharge device 1, the coating apparatus 2, the coating apparatus 3, the winding device 4, and the optical diaphragm are placed on the discharge device 1. After the glue apparatus 2 is applied to the membrane, the optical diaphragm is separated from the protective diaphragm, and the optical film is coated on the plate surface, and the protective film sheet is transferred to the winding device 4 for recovery. The film apparatus 3 includes a transmission belt 31, and a first compression device 32, a second pressing device 33, and a drying device 34 are provided, and the drying device 34 is disposed in the first pressure. Between the device 33 and the second pressing device 34; the upper portion of the transmission belt 31 is also provided with a protective film and an optical film separated separation block 35.

[0021]The coating apparatus 2 includes a nozzle 21, a first coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com