Cold and hot primary air forced mixing system and method for inlets of double-inlet and double-outlet coal mill

A double-inlet, double-outlet, forced mixing technology, applied in the system field, can solve problems such as the temperature deviation of the mixed air at the inlet of both ends of the coal mill, the increase of the outlet temperature of the coal mill, and the inconsistency of the outlet temperature of the coal mill, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

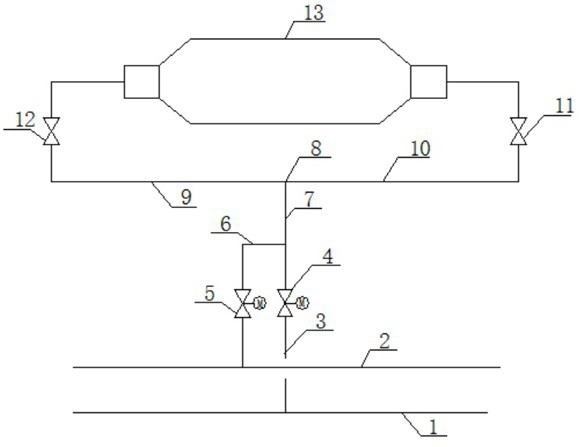

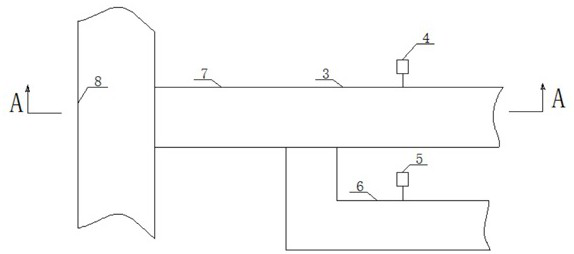

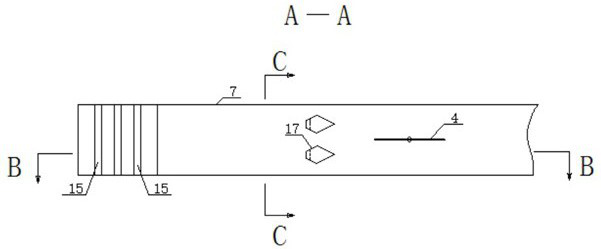

[0020] see Figure 1 to Figure 5 In this embodiment, the double-inlet and double-outlet coal mill inlet cold and hot primary air forced mixing system includes a hot primary air main pipe 1, a cold primary air main pipe 2, a hot primary air pipe 3, a hot primary air regulating baffle 4, and a cold primary air main pipe 1. Primary air adjustment baffle 5, cold primary air duct 6, mixing air duct 7, split tee 8, left mixing air branch pipe 9, right mixing air branch pipe 10, coal mill 13, cold primary air corner deflector 16 , primary cold air diversion device 17 and primary cold air spout 18; one end of primary primary air pipe 3 and primary primary air pipe 6 is connected to the side wall of primary primary air primary pipe 1 and secondary primary primary air primary pipe 2 respectively, The adjusting baffle 4 and the cold primary air adjusting baffle 5 are arranged on the hot primary air pipe 3 and the cold primary air pipe 6 respectively, and the shafts of the hot primary air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com