Linear manipulator comprising planet row transmission structure

A technology of transmission structure and manipulator, which is applied in the field of medical equipment, can solve the problems of high total friction force of steel wire rope, long wire rope routing path, complicated manipulator circuit, etc., and achieve the effect of convenient operation, reduction of total friction force and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

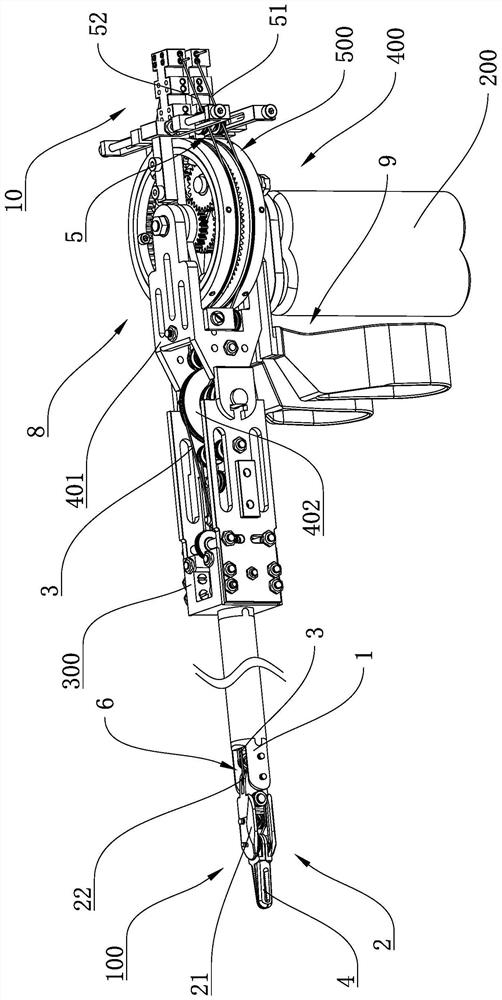

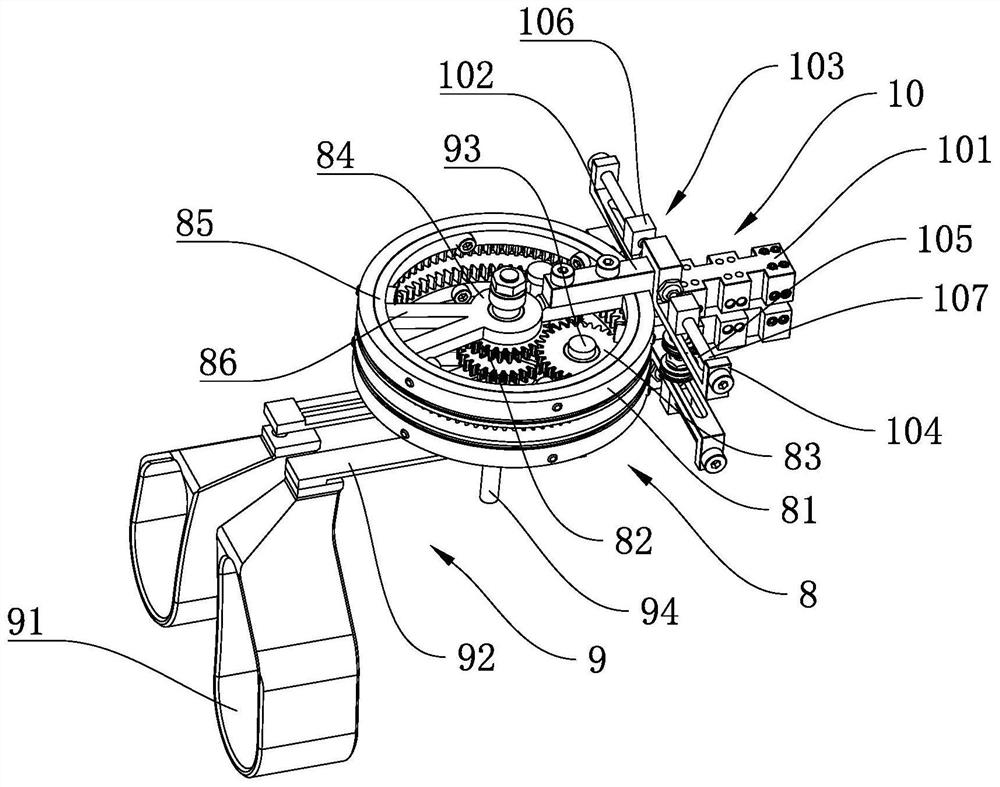

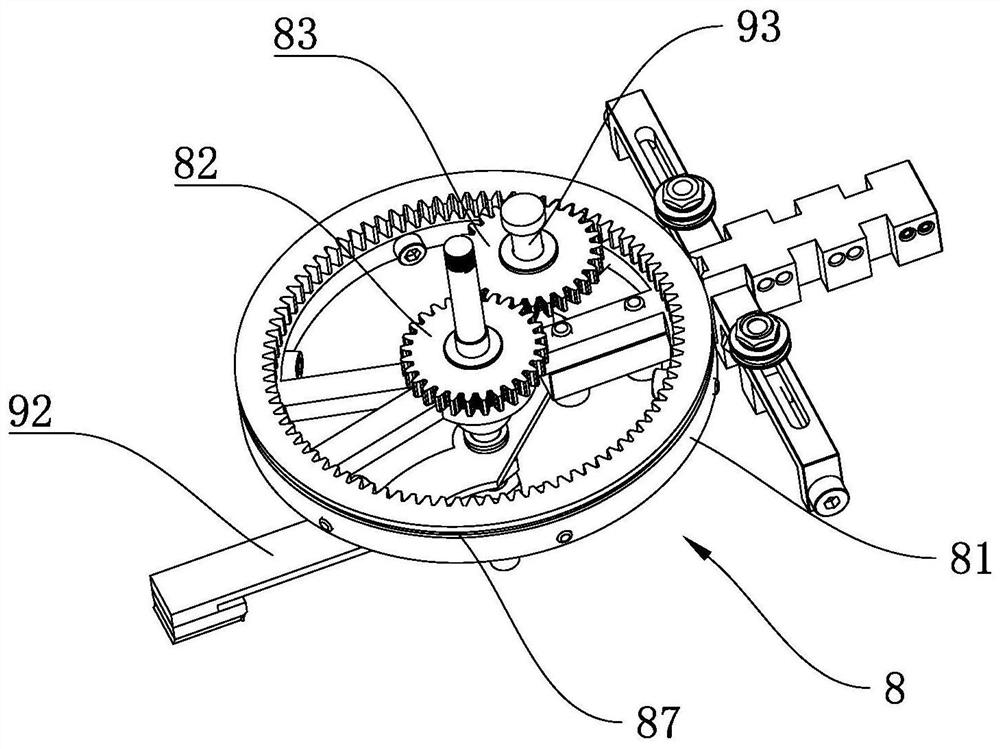

[0032] Such as figure 1As shown, a linear manipulator including a planetary row transmission structure includes a manipulator body 300, an operating assembly 400 is rotatably connected to the manipulator body 300, and a gripping portion 200 is connected to the operating assembly 400. The operating assembly 400 includes An operating frame 401, the operating frame 401 is rotationally connected with the manipulator body 300, the grip part 200 is connected to the operating frame 401, the operating frame 401 is connected with a planetary row assembly 8, and the planetary row assembly 8 is connected with a power input Assembly 9 and power output assembly 10, moving the power input assembly 9 can drive the power output assembly 10 to move, the end of the manipulator body 300 away from the operating frame 401 is provided with a clamping assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com