Tea leaf tedding device

A technology of tea and buffer device, which is applied in the direction of tea processing before extraction, etc., can solve the problems of inconvenient turning of tea leaves, difficulty in controlling the thickness of tea leaves on the plate, affecting the effect of spreading green, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

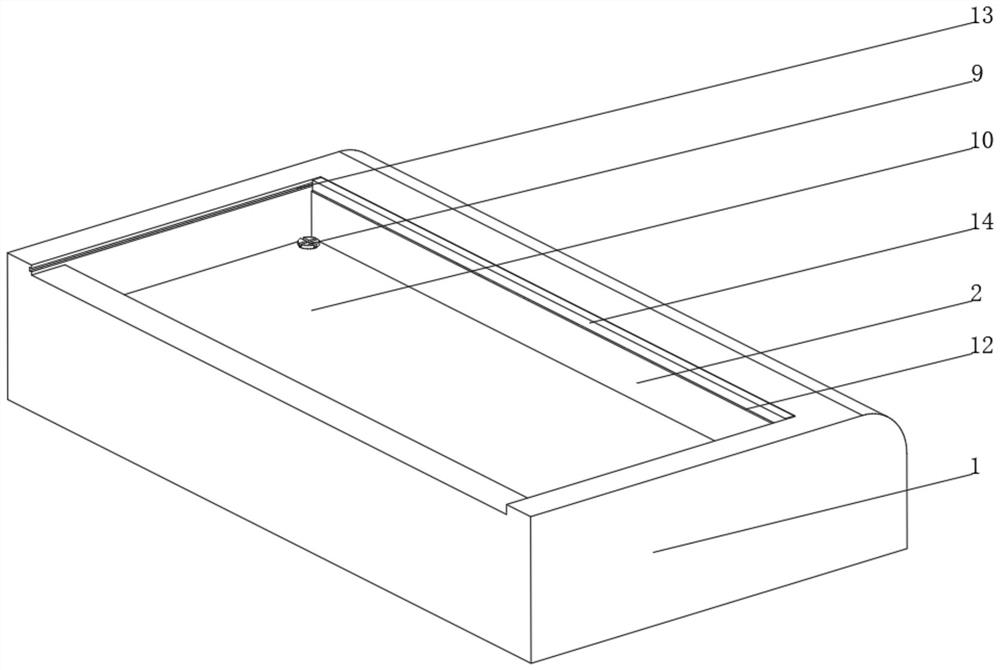

[0031] see Figure 1-3 , the present invention provides a kind of technical scheme: a kind of green tea spreading device, comprises green spreading platform 1, green spreading groove 2 is opened on the top top of green spreading platform 1, and air groove 3 is opened on the bottom of inner wall of green spreading groove 2, and air groove 3 The interior is provided with a ventilation fan 4, the bottom of the air groove 3 is connected with an air inlet duct 5, and the end of the air inlet duct 5 away from the air groove 3 runs through the stand 1 and extends to the outside of the stand 1, and the bottom of the inner wall of the air groove 3 is fixed around the bottom Connected with an electric telescopic rod 6, the top of the electric telescopic rod 6 is fixedly connected with a cylinder 7, and the top of the cylinder 7 is fixedly connected with a buffer device 8, and the top of the buffer device 8 is fixedly connected with a stall net 10 through a bolt 9, and one side of the top...

Embodiment 2

[0034] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the code height device 14 includes a code height slide bar 141, and both ends of the code height slide bar 141 are rotatably connected with rollers 143, and one side of the code height slide bar 141 is provided with Rotating groove 144, both sides of rotating groove 144 inner wall are all fixedly connected with clockwork spring 145, and the side of clockwork spring 145 away from rotating groove 144 inner wall is fixedly connected with arc-shaped hook plate 146, and the top of code height slide bar 141 is provided with extending slide Slot 147, the extension chute 147 inner wall is slidably connected with extension plate 148, and one side of code height device 14 is provided with rotating groove 144 and arc-shaped hook plate 146, which can prevent the pushed tea leaves from slipping away from the bottom of code height slide bar 141, and set There is a clockwork spring 145, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com