Soldering paste solderability testing device and method under simulated backflow temperature curve

A technology of reflow temperature and testing equipment, which is applied in the direction of measuring equipment, instruments, scientific instruments, etc., can solve the problems that there is no separate measurement of solder paste, and the change of solderability of the measured object cannot be truly restored, so as to ensure accuracy and guarantee The effect of full exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

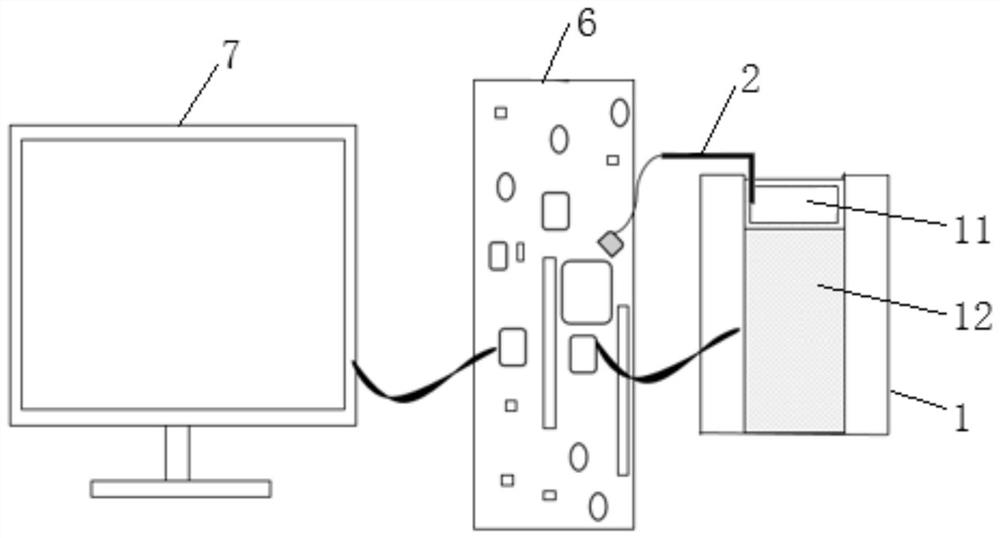

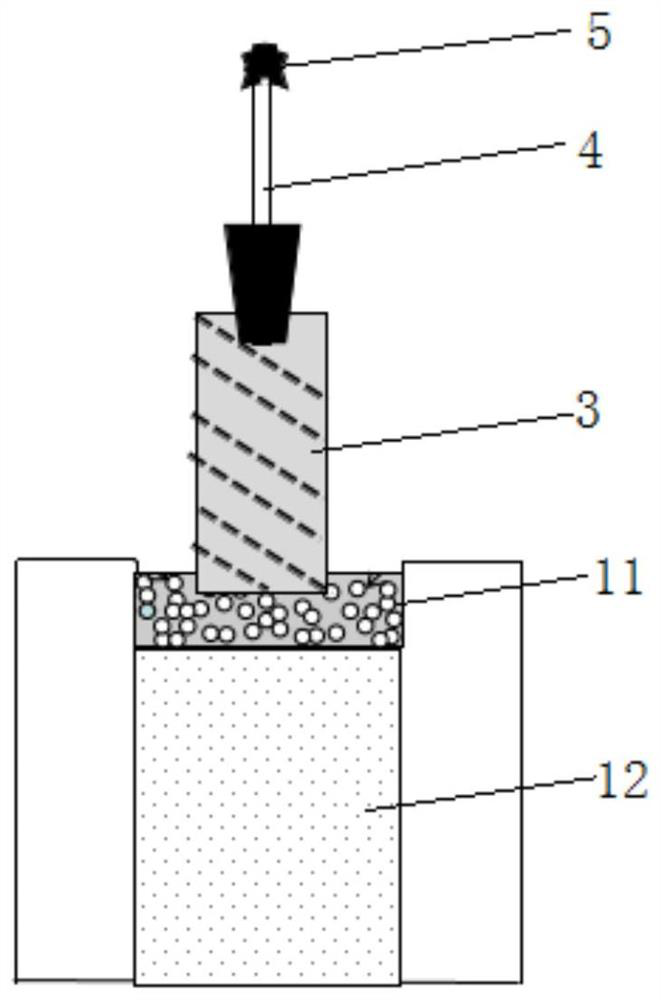

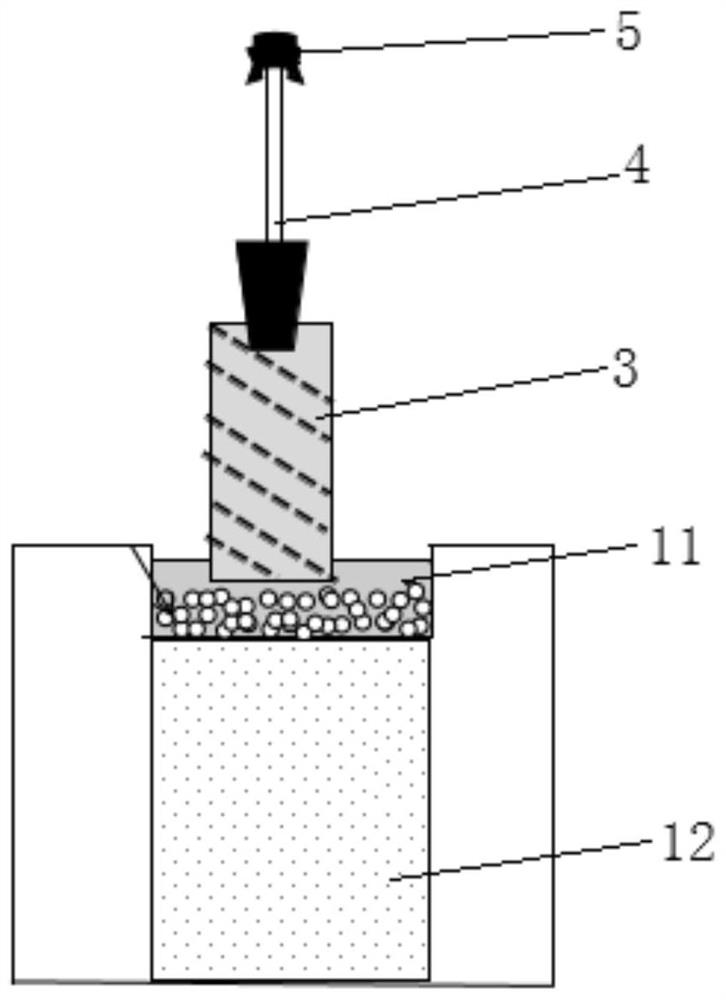

[0036] Such as figure 1 As shown, the present embodiment provides a solder paste solderability testing device under a simulated reflow temperature curve, the device includes a tin furnace 1, the tin furnace 1 includes a tin bath 11 for holding solder paste and a tin bath for heating The heating core 12 of 11, the temperature sensor 2 is arranged in the tin bath 11, and the metal hanger 3 for the absorption of the melted solder paste is hung above the tin bath 11, and the metal hanger 3 is used for inserting tin in the solderability test. In the groove 11, the metal hanger 3 is hung on the force sensor 5 used to obtain the wetting force of the metal hanger 3 during the test,

[0037] The unit also includes:

[0038] An elevating platform for adjusting the insertion depth of the metal hanger 3 into the tin bath 11, a controller for controlling the real-time temperature in the tin bath 11 as the simulated reflow temperature curve changes, collecting real-time wetting force and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com