Continuous metering equipment for granular materials

A technology for granular materials and measuring equipment, which is applied in the direction of weighing equipment, weighing, and measuring devices for materials with special properties/forms, and can solve problems such as difficult implementation and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

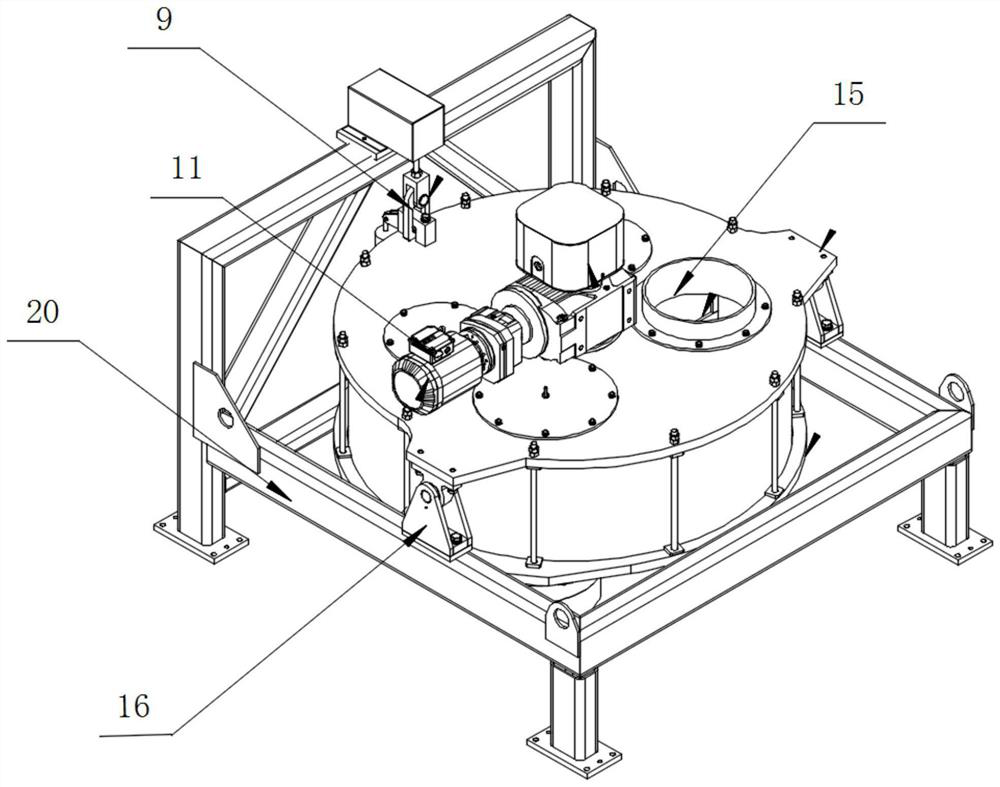

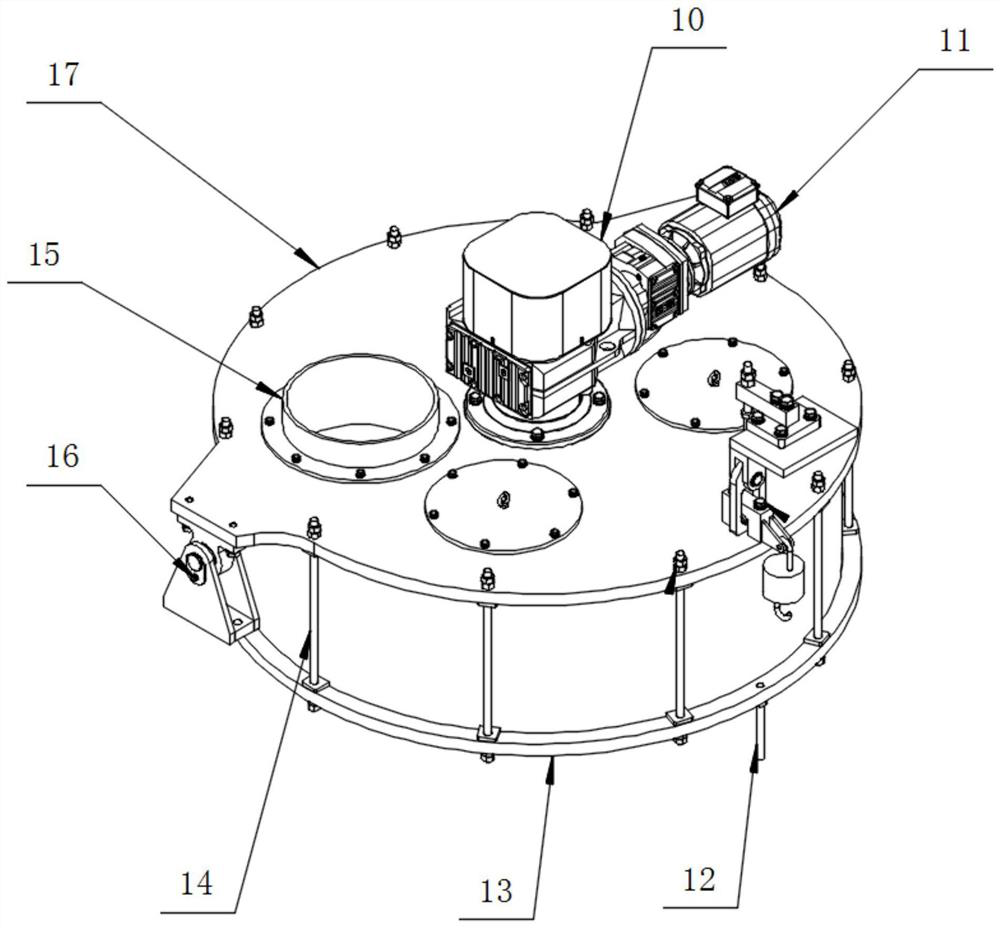

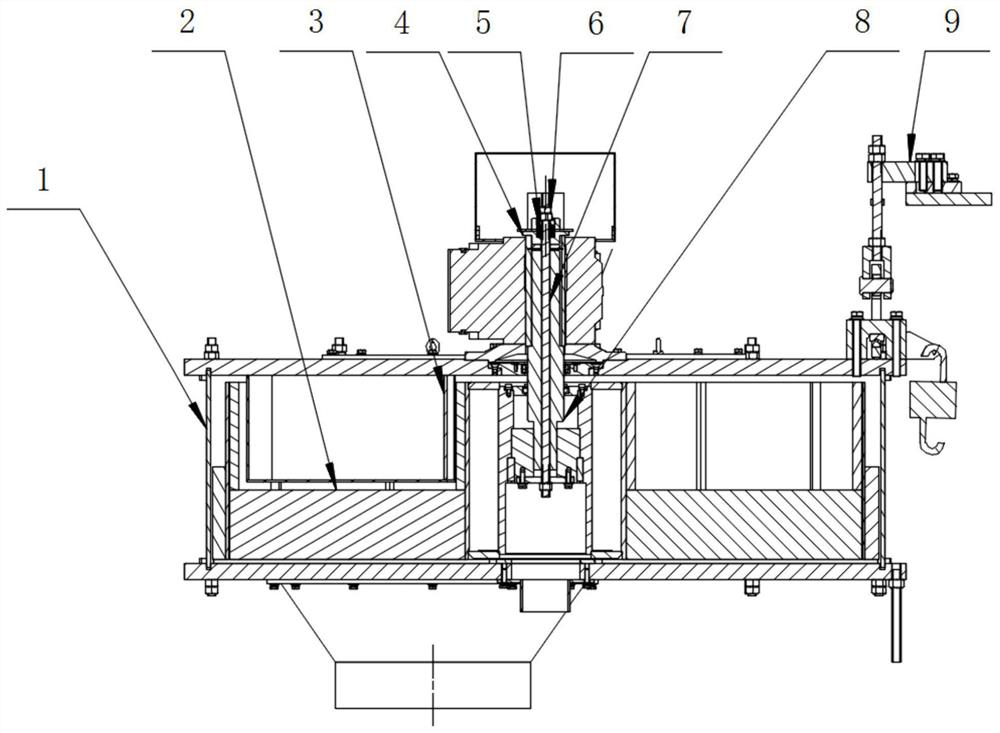

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In conjunction with the accompanying drawings, a device that can be used for continuous metering of granular materials includes a frame body 20 and a housing. The housing includes an upper flange 17, a jacket and a lower flange 13. The upper flange 17 and the lower flange 13 is provided with a jacket, the upper flange 17 and the lower flange 13 are connected by a connecting rod 14, the upper flange 17 is provided with a feed port 15, and the lower end of the upper flange 17 is provided with a stopper Plate 3, the lower flange 13 is provided with a discharge port 18, the outer casing is provided with a rotor 2, the center of the lower flange 13 is provided with a slag discharge port 19, and the center of the upper flange 17 is rotated A shaft 8 is connected, the lower end of the shaft 8 is connected to the rotor 2, the rotor adjustment screw 7 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com