Rotary drilling rig operation platform for upper-soft lower-hard stratum and construction method thereof

A technology for operating platforms and rotary drilling rigs, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of irreconcilable installation errors, poor universality of concrete structures, and poor applicability of different pile positions, etc., to achieve increased Overall load-bearing area, the effect of reducing the stress of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

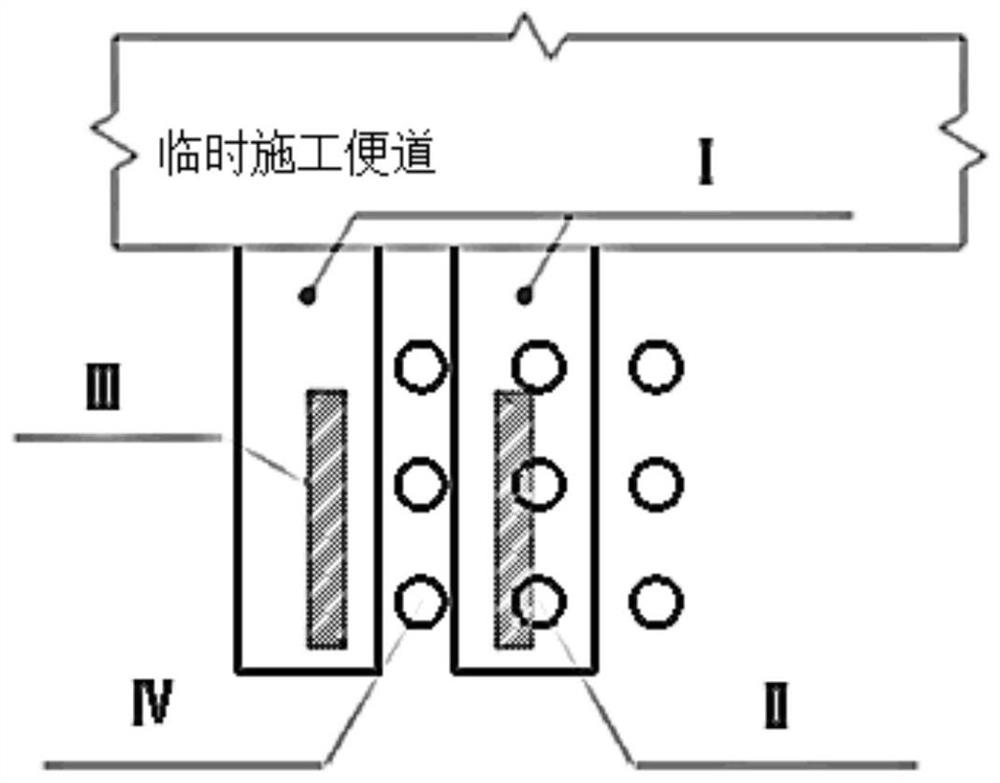

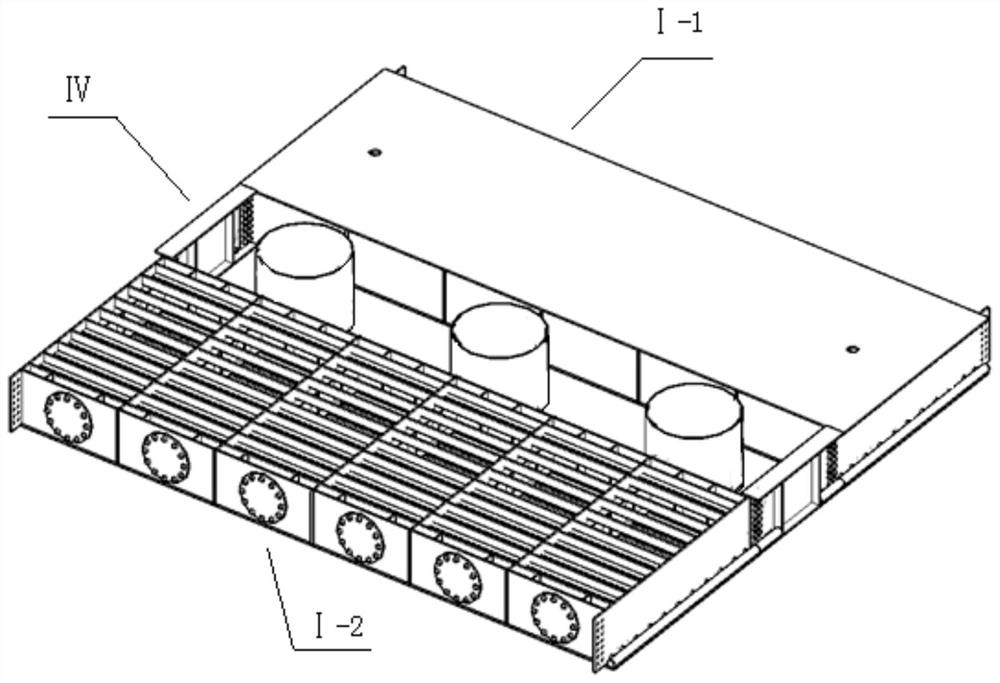

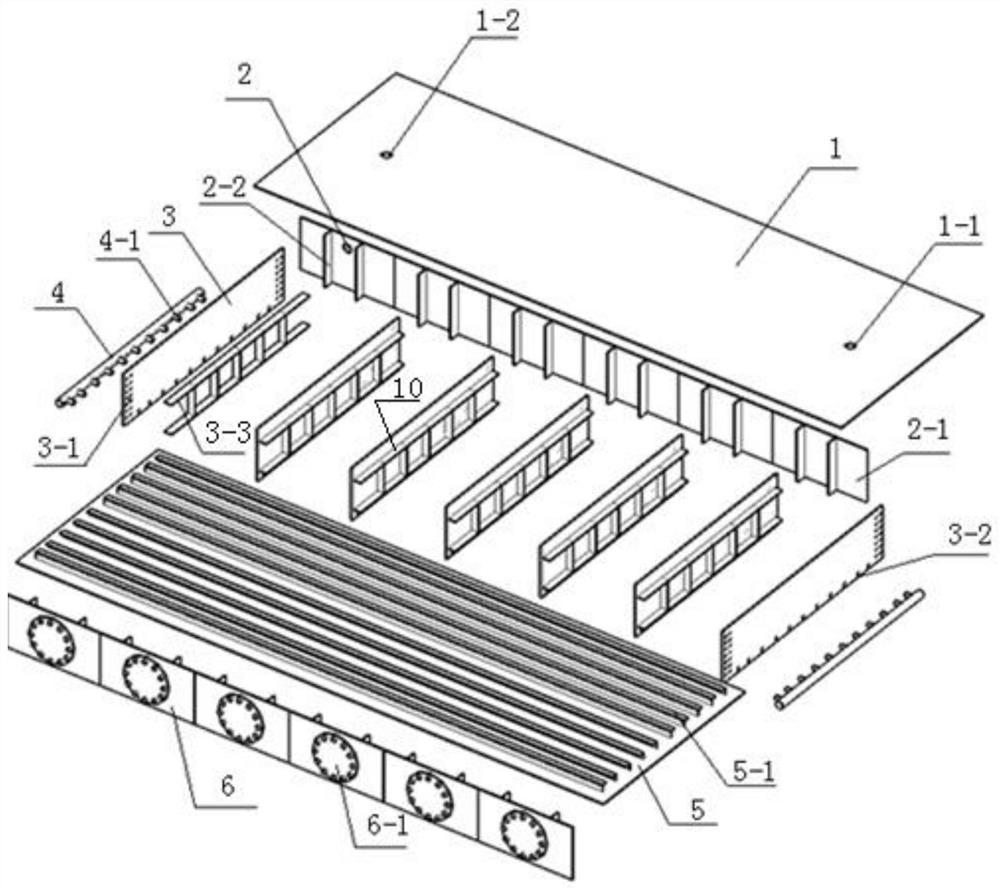

[0078] In this embodiment, the prefabricated platform adopts an all-steel box structure, and a rotary excavator crawler area III is provided on the top surface of the box along the length direction.

[0079] 1.1.1 All steel box structure

[0080] In the double-raft system operating platform I, the area of the single prefabricated platform is relatively large, reaching 24-36m 2 , in order to balance "structural rigidity" and "hoisting weight", the prefabricated platform described in this embodiment adopts an all-steel box structure. the reason is:

[0081] A: The upper limit of the hoisting weight of the temporary measure structure is 18 tons, that is, the maximum weight that can be hoisted by a single 75-ton truck crane within a 6m operating radius - the weight of the measure structure exceeds 18 tons, which means that the truck crane needs to be increased in the project site. Specifications (the hoisting time of a single panel is short, and the crane is purely used for th...

Embodiment 2

[0173] The difference between this embodiment and Embodiment 1 is that the all-steel prefabricated platform different from that described in Embodiment 1 is used instead of a steel-concrete prefabricated platform. Specifically, the steel-concrete prefabricated platform is a closed box structure, It includes a concrete panel and a box-shaped steel support structure; the concrete panel is connected to the box-shaped steel support structure through welding studs 1-4;

[0174] The inner cavity of the steel-concrete prefabricated platform is set as a plurality of interconnected compartments along the length extension direction, and at the same time, the steel-concrete prefabricated platform is provided with a number of diversion holes a3-2 at both ends in the length direction;

[0175] The concrete panel is provided with a maintenance manhole 6-1 corresponding to each compartment, and the maintenance manhole 6-1 is sealed through the maintenance cover; meanwhile, the concrete panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com