Cement concrete pavement patching machine

A technology for repairing cement concrete and pavement, which is applied in road repair, roads, roads, etc. It can solve the problems of easy traffic accidents, high work intensity, casualties, etc., and achieve the goal of facilitating work progress, improving the degree of automation, and facilitating stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

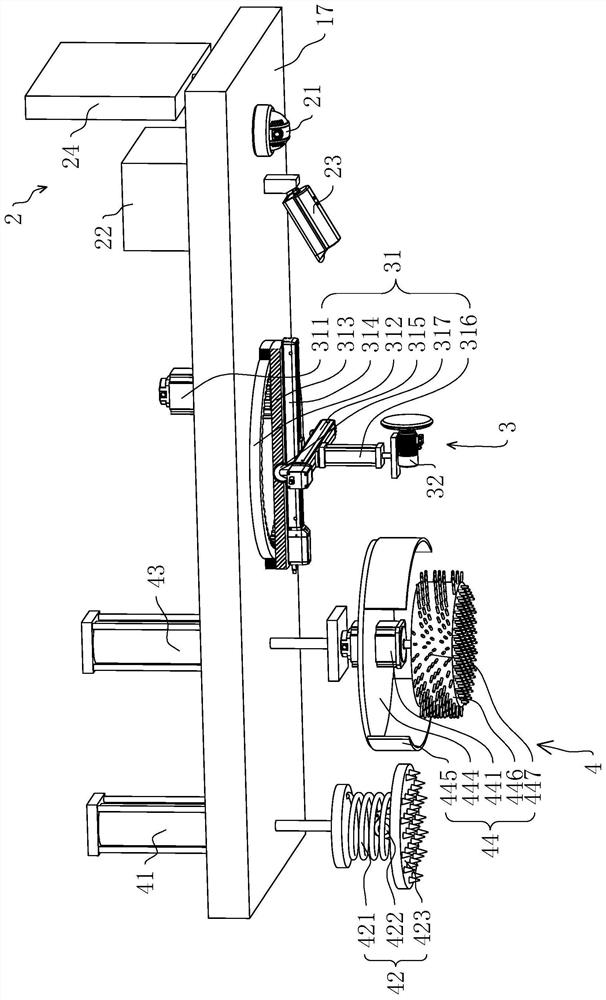

[0040] The following is attached Figure 1-5 The present invention is described in further detail.

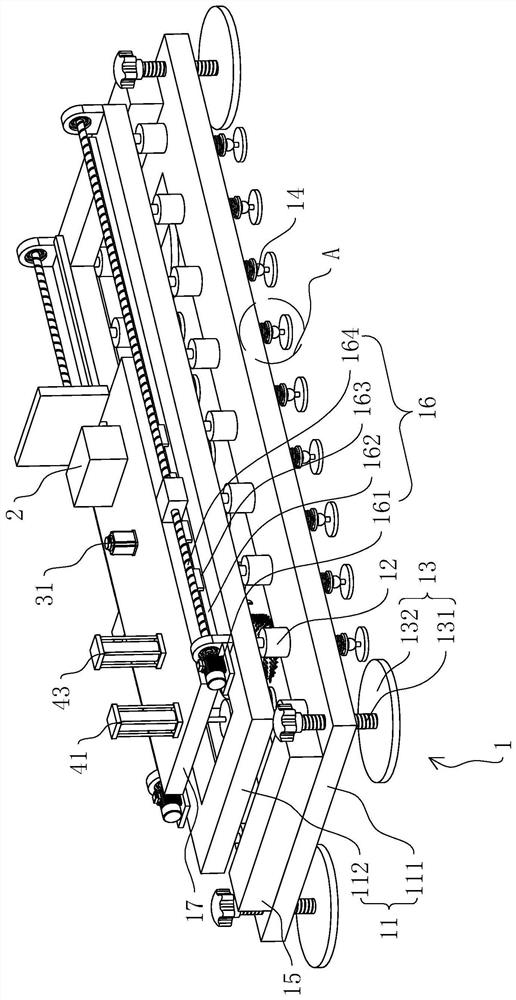

[0041] The embodiment of the application discloses a cement concrete pavement patching machine. refer to figure 1 and figure 2 , The cement concrete road patching machine includes a mobile device 1 and a visual measurement device 2 , a road surface cutting device 3 and a road surface cleaning device 4 sequentially arranged on the mobile device 1 .

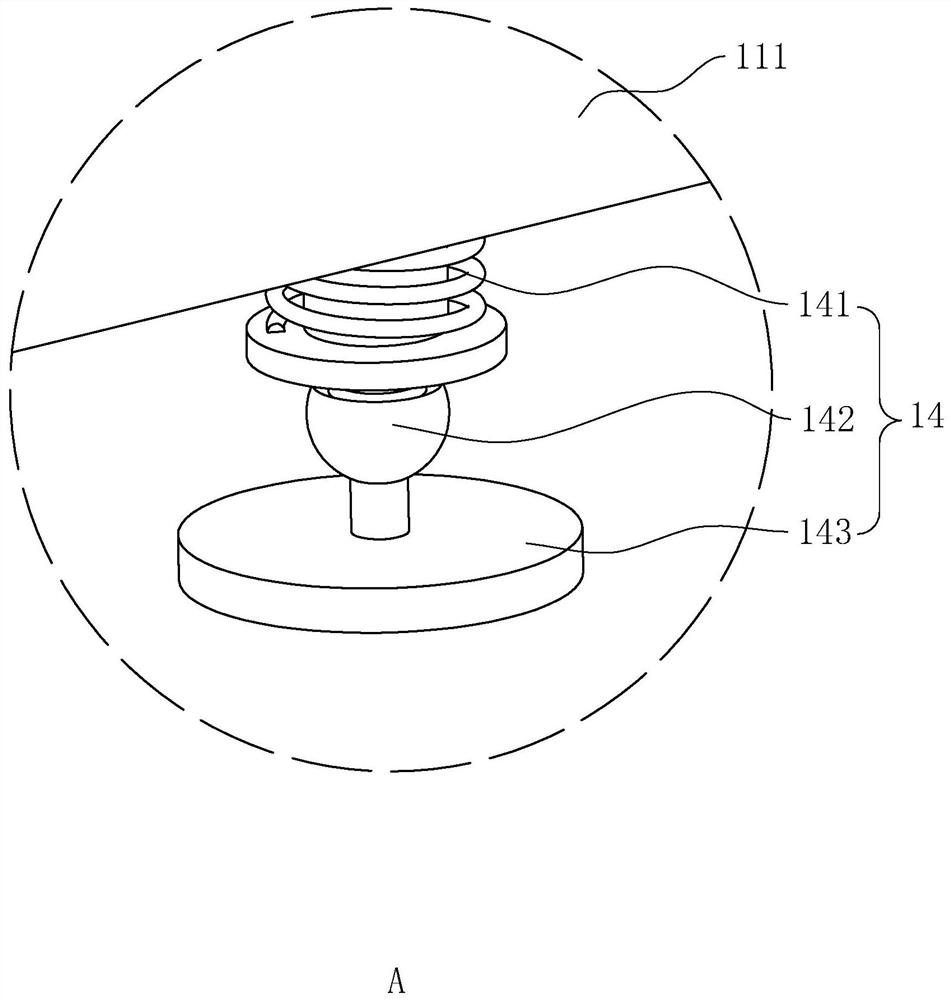

[0042] refer to figure 1 , the mobile device 1 includes a fixed frame 11, the fixed frame 11 includes a first bracket 111 and a second bracket 112 arranged above the first bracket 111, a shock absorbing spring 12 is arranged between the first bracket 111 and the second bracket 112, The damping spring 12 is configured as a gas spring, one end of the gas spring is fixed on the first support 111 , and the other end of the gas spring is fixed on the second support 112 .

[0043] refer to figure 1 , the first bracket 111 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com