Backlight source assembling device

A technology for assembling devices and backlight sources, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficulty in realizing automatic assembly of light guide plates, low assembly efficiency, etc., so as to improve assembly efficiency and assembly quality consistency, avoid light leakage, The effect of ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

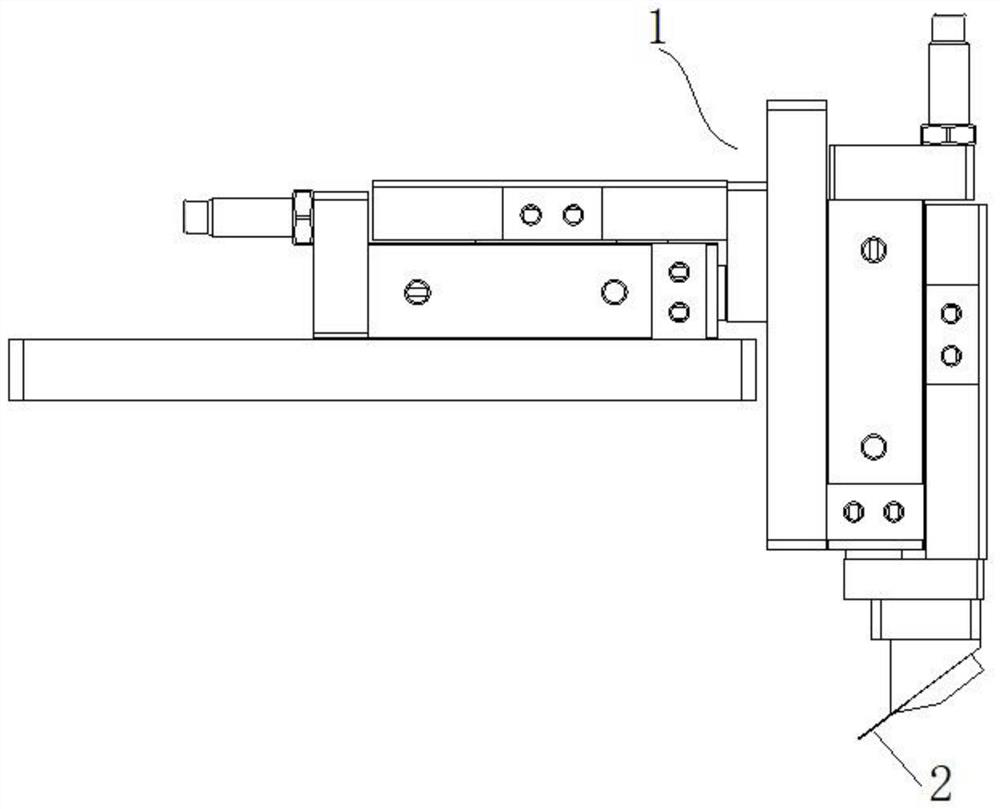

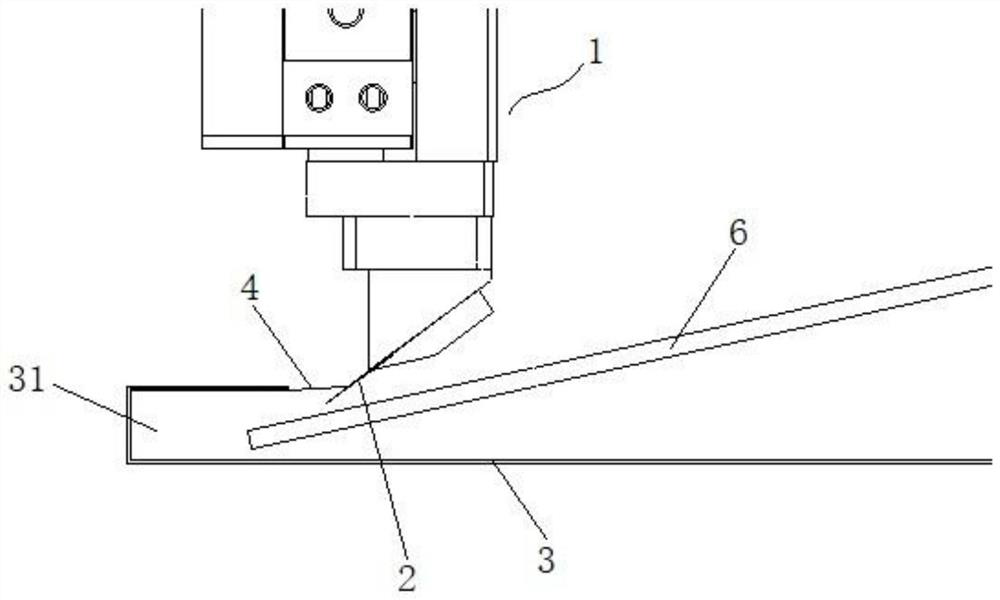

[0023] like figure 1 and figure 2 As shown, a backlight assembly device mainly includes a moving assembly 1 and a paddle 2, and the moving assembly 1 has at least the first degree of freedom of movement along the depth direction of the U-shaped groove of the U-folding backboard 3 and perpendicular to the U The second degree of freedom of movement in the direction of the surface of the folding backboard, the paddle 2 is driven to move by the moving assembly 1, and the paddle 2 is inserted into the U-shaped notch under the drive of the moving assembly 1 and connected to the U-shaped groove 31 The shading strip 4 on the side wall is in contact, and the shading strip 4 is attached to the inner side wall of the U-shaped groove, and extends out of the mouth of the U-shaped groove to achieve the purpose of shading. The surface direction of the U-fold backboard moves toward the outside of the side wall of the U-shaped groove, so that the plectrum 2 turns the light-shielding strip 4 ...

Embodiment 2

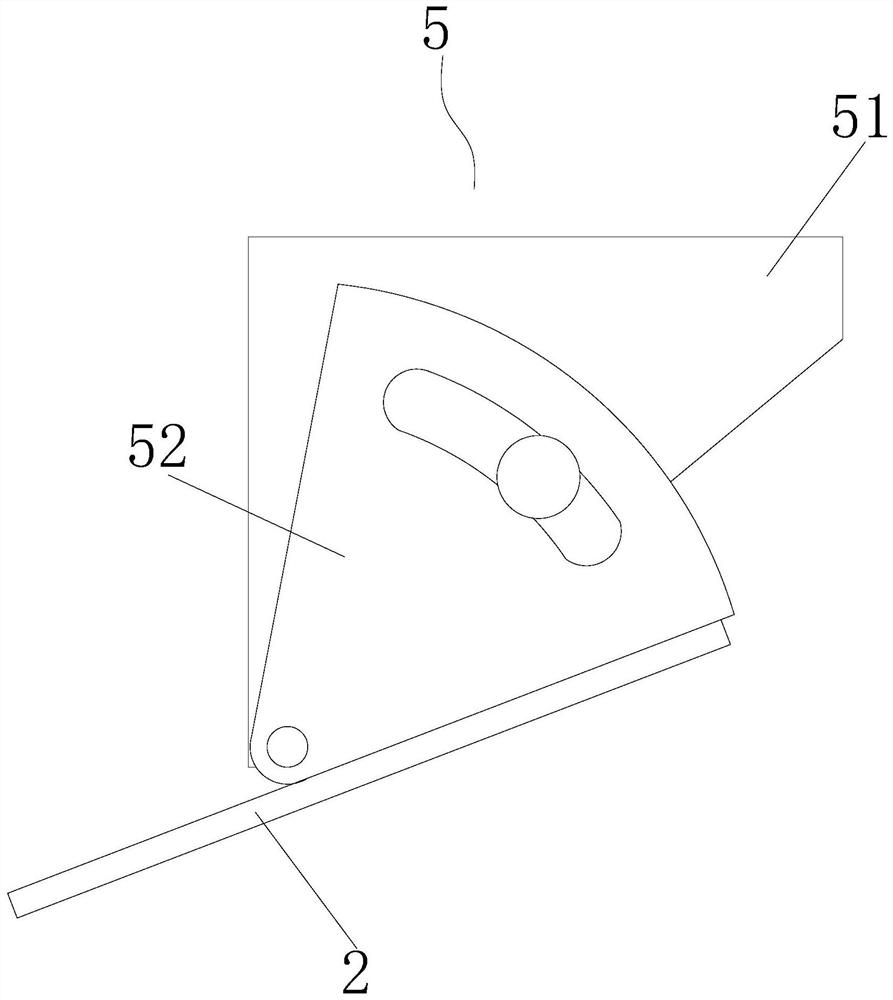

[0028] like image 3 As shown, the difference from Embodiment 1 is that the plectrum 2 is detachably connected to the mobile assembly 1, which is easy to replace and maintain, and the angle of the plectrum 2 inclined to the surface direction of the U-fold backboard 3 can be adjusted. Adjustment, so as to be able to adapt to the assembly of backlight sources of different specifications, and increase the scope of application. Specifically, the paddle 2 is connected to the moving assembly 1 through the adjusting assembly 5, and the adjusting assembly includes a base part 51 connected to the moving assembly 1 and an adjustable part 52 hinged on the base part 51, so The above-mentioned adjustable part 52 is provided with an arc-shaped chute, and the above-mentioned base part 51 is provided with a fixing hole, and the bolt passes through the chute and is locked in the fixing hole. On the adjustable part 52, the adjustable part 52 can be rotated freely by loosening the bolts. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com