Drum-type steel fiber uniform distribution device and steel fiber distribution platform

A steel fiber and drum-type technology, applied in the field of concrete mixing equipment, can solve the problems of inability to effectively control the uniformity of steel fibers, affect the quality of concrete production, and fail to adapt to streamlined production, so as to prevent direct contact, facilitate feeding, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

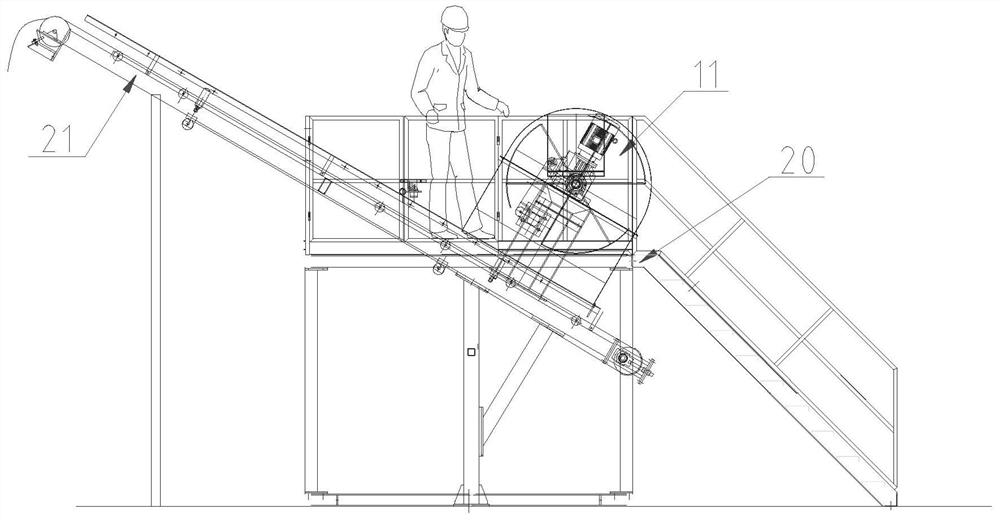

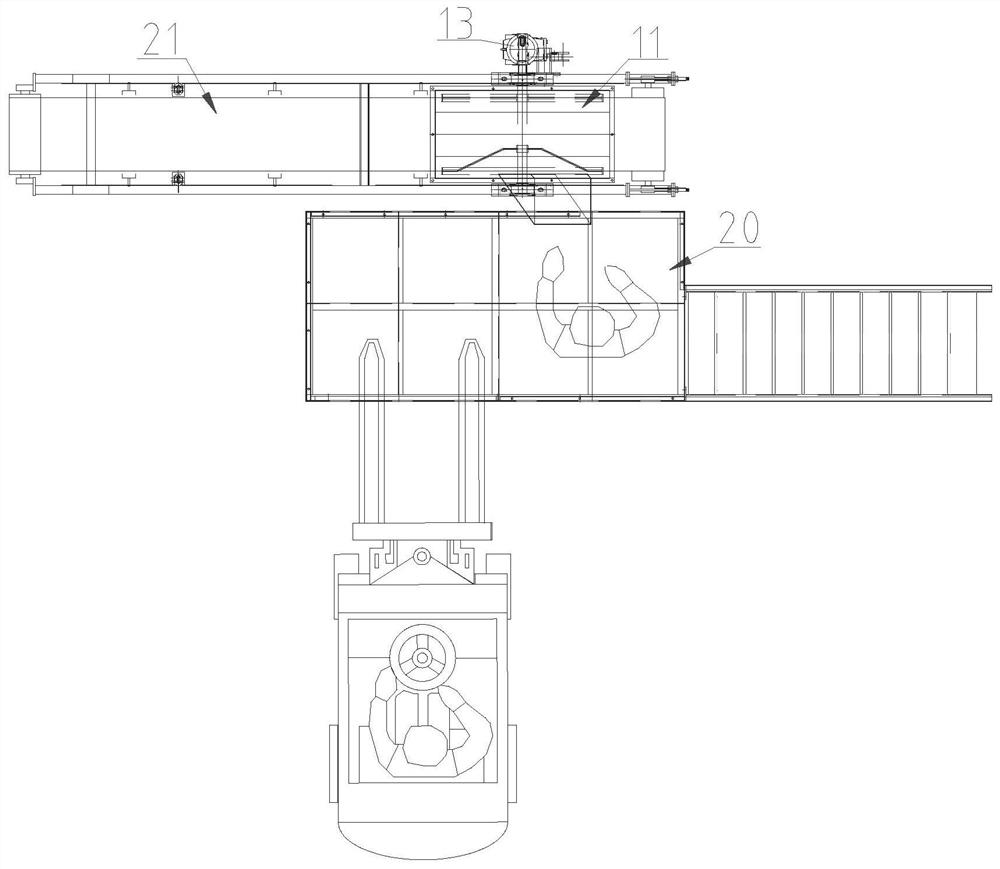

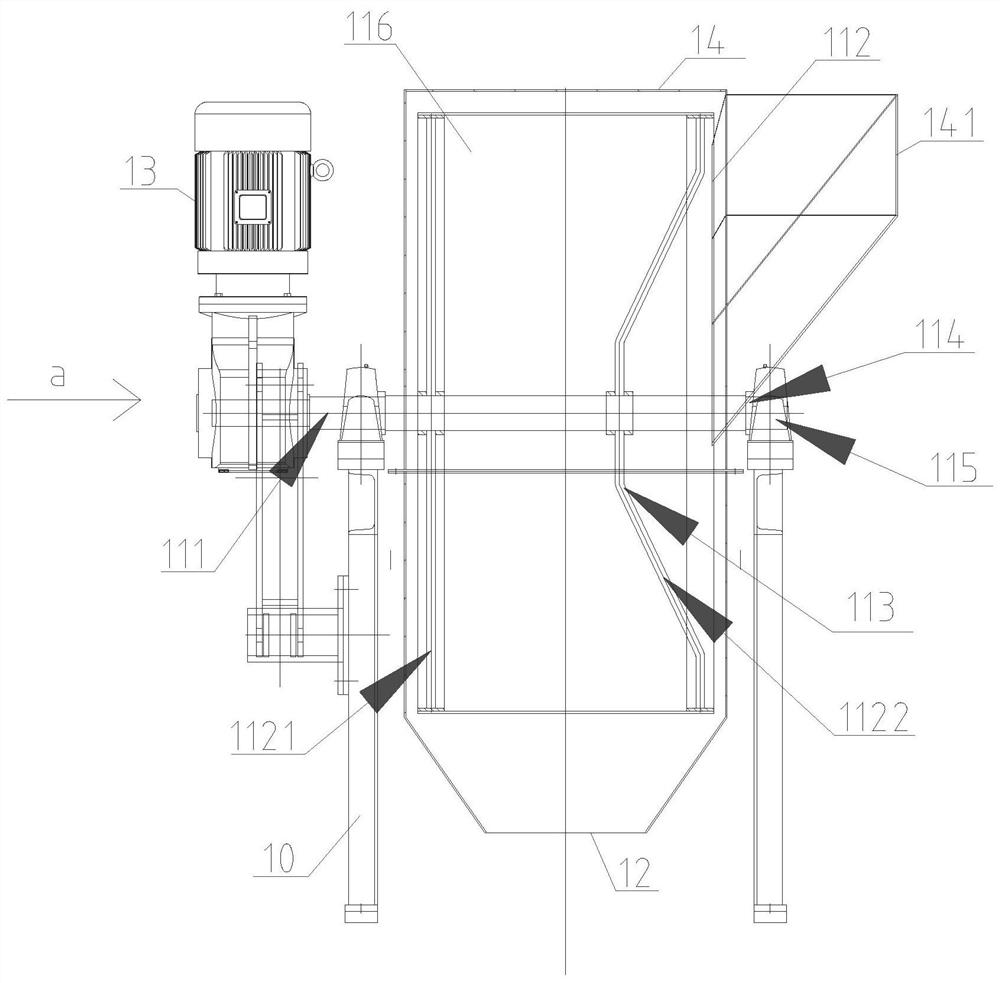

[0033] Please refer to Figure 1-Figure 7 As shown, a drum-type steel fiber uniform distribution device includes a bracket, a drum assembly, a lower box 12 and a motor 13, the drum assembly is arranged on the bracket, the lower box 12 is arranged on the bracket and is located at the bottom of the drum assembly, and the motor 13 Located on the outside of the support, the top of the lower box 12 is provided with a feed inlet, and the bottom of the lower box 12 is provided with a discharge outlet. The drum assembly includes a drum 11 and a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com