Miniature vibration motor

A vibrating motor and miniature technology, applied in the field of motors, can solve the problem of single function and achieve the effect of heat dissipation function, good heat dissipation performance and thin space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

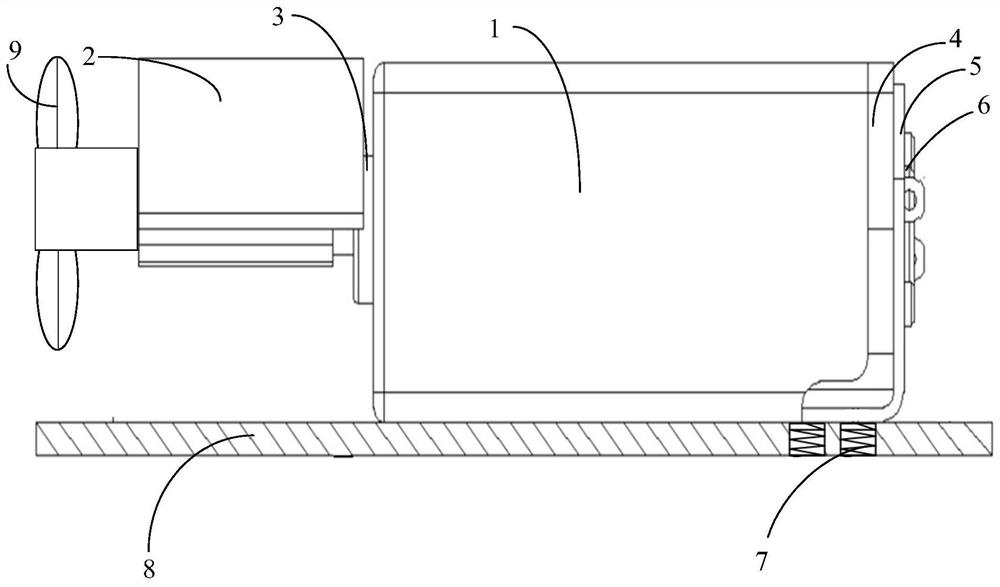

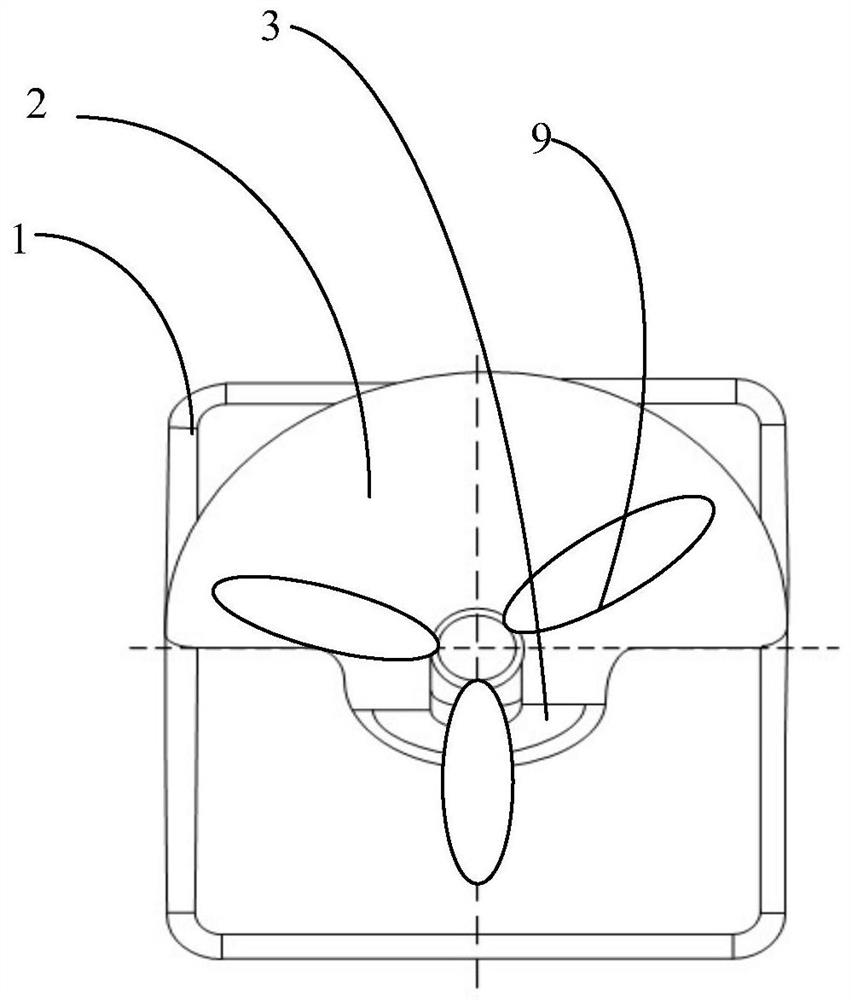

[0013] The present invention proposes a micro vibrating motor, referring to figure 1 and figure 2 , the miniature vibrating motor includes a stator 2, a rotor 3 and a motor casing 1; the rotor 3 includes a coil winding, a rotor 3 iron core, a commutator and a central shaft, and one end of the central shaft is provided with an end cover 5, so The end cover 5 is set on one end of the motor housing 1; the stator 4 is sleeved on the rotor 3; the stator 4 is used to generate a rotating magnetic field and provide the rotating magnetic field to the rotor 3 The rotor 3 is used to rotate in the rotating magnetic field generated by the stator 4 to generate a load torque, and transmit the load torque to the standard vibrator 2 and the exhaust vibrator 9 through the central shaft; The standard vibrator 2 is eccentrically sleeved on the central shaft and located on one side of the motor casing 1; the exhaust vibrator 9 is sleeved at the end of the central shaft close to the standard vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com