Cavity making tool for salt cavern gas storage

A technology for gas storage and cavity making, which is applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as the inability to increase the speed of clean water, achieve significant economic and social benefits, improve construction benefits, and save cavity making time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

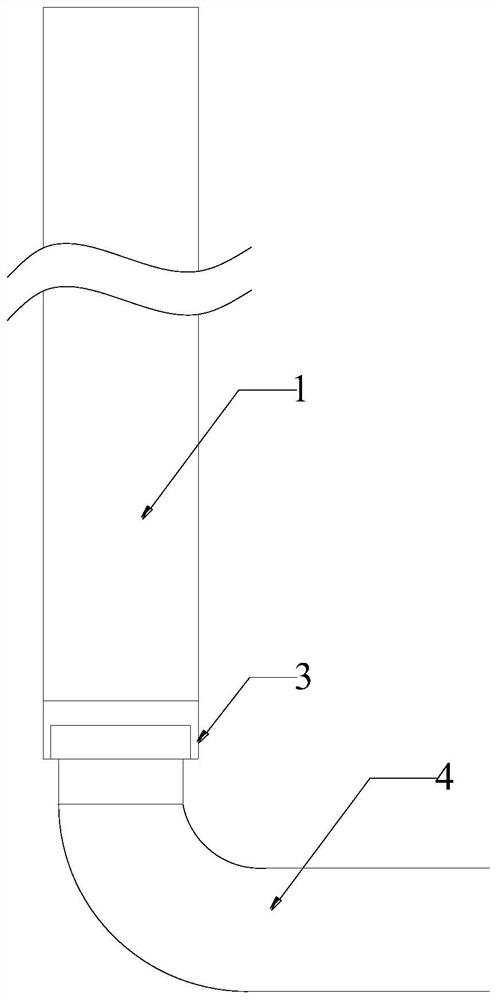

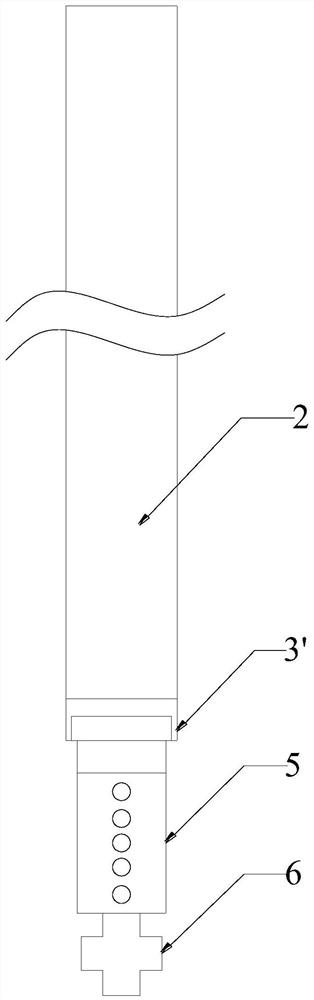

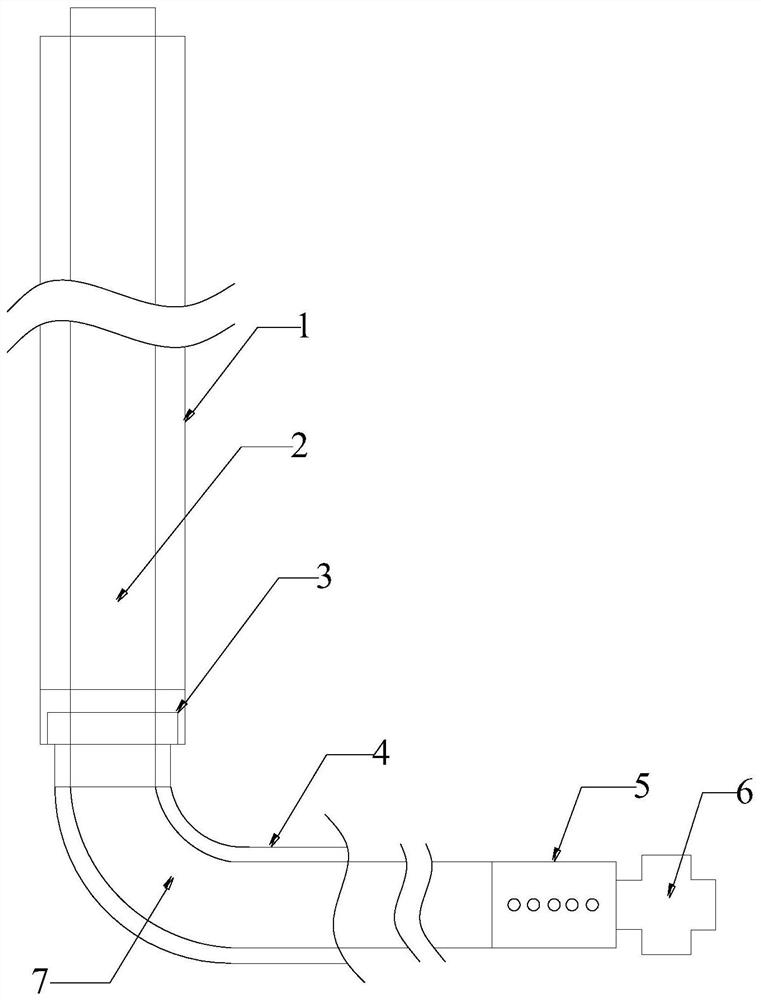

[0029] Such as Figure 1 to Figure 5 As shown, the cavity building tool for salt cavern gas storage in this embodiment includes an outer pipe 1, an inner pipe 2, a first universal steering nipple 3, a second universal steering nipple 3', and a guide pipe 4 (the length of the curved section is about 30m, the central angle of the bending section is 90°), the steering power nipple 5 and the high-pressure nozzle 6; the outer pipe is sleeved outside the inner pipe; the upper end of the first universal steering nipple is connected to the outer pipe, and the lower end is connected to the guide pipe to The outer pipe and the guide pipe can rotate relatively; the upper end of the second universal steering nipple is connected to the inner pipe, and the lower end is connected to the steering power nipple, so that the inner pipe and the steering power nipple can rotate relatively; the high-pressure nozzle is set on the steering power nipple Bottom; the inner pipe, the second universal ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com