Automatic winding equipment and winding method for motor coil

An automatic winding and coil technology, applied in electric components, manufacturing motor generators, electrical components, etc., can solve the problems of difficult alignment of enameled wires, affecting the winding efficiency of pay-off reels, and low threading efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

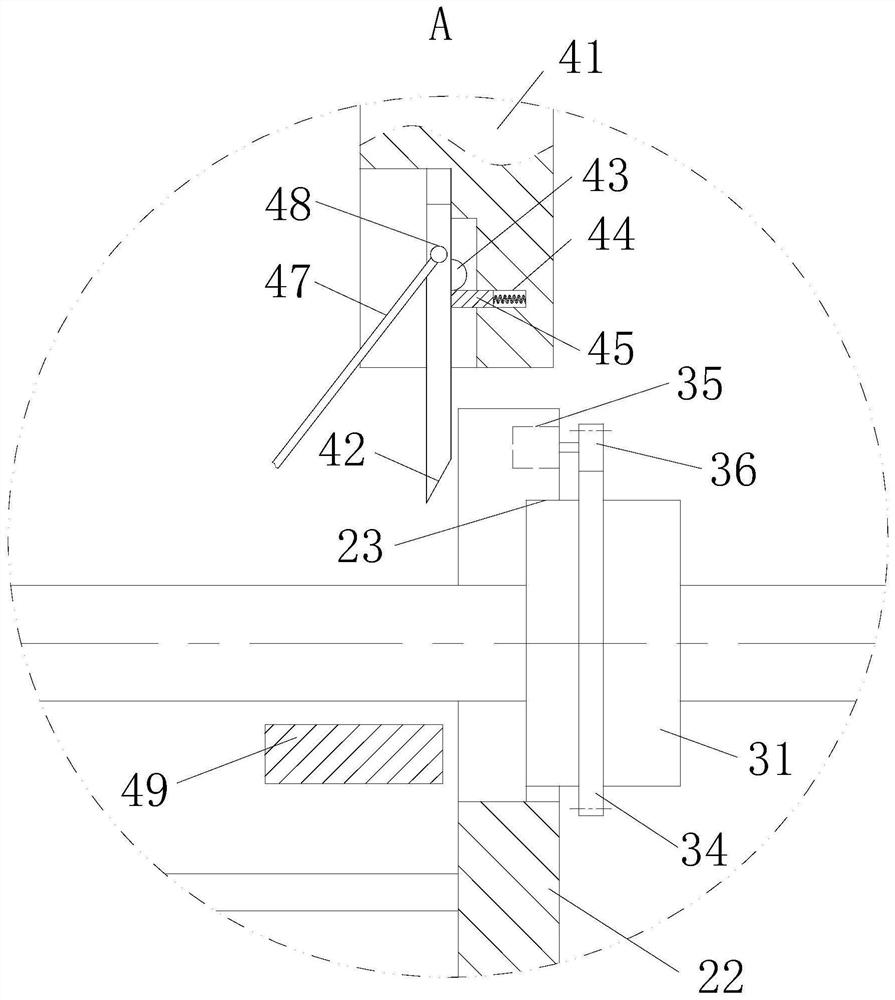

[0035]As an embodiment of the present invention, the clamping unit 3 includes a slip ring 31 and a wedge block 32; the slip ring 31 is opened away from the side of the fork 22, and the wedge block 32 is rounded. The cone hole 33 is slid in the inner circumference and the tapered hole 33; the outer circumferential insulation of the slip ring 31, the outer ring gear 34, the front and the outer gear 34, and the drive motor 35, the drive motor 35 The gear 36 of the output shaft is engaged with the outer gear 34; after the wedge block 32 is tensioned, the push rod 21 pushes the blade 22 toward the direction away from the slider 2, so that the wedge block 32 is driven in the fork 22. The lower cone hole 33 slides, and then the wedge block 32 moves in a direction in which the slide 31 is close to the center and extruded the lacquer line in the slide ring 31, thereby continuously clamping the enamel line, while driving the motor 35 drives the gear 36 to rotate, the gear 36 is driven The rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com