Method for preventing and controlling water inrush in mined-out collapse area through sill-pillar-free caving method

A caving method and no bottom pillar technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve problems such as water inrush and flooding of wells, unsatisfactory plans, and changes in mining working faces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

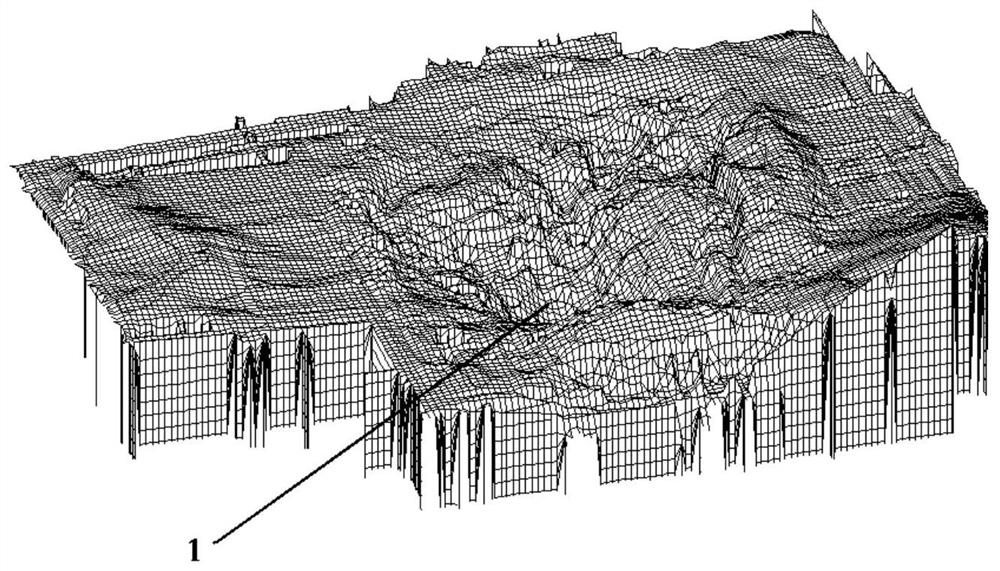

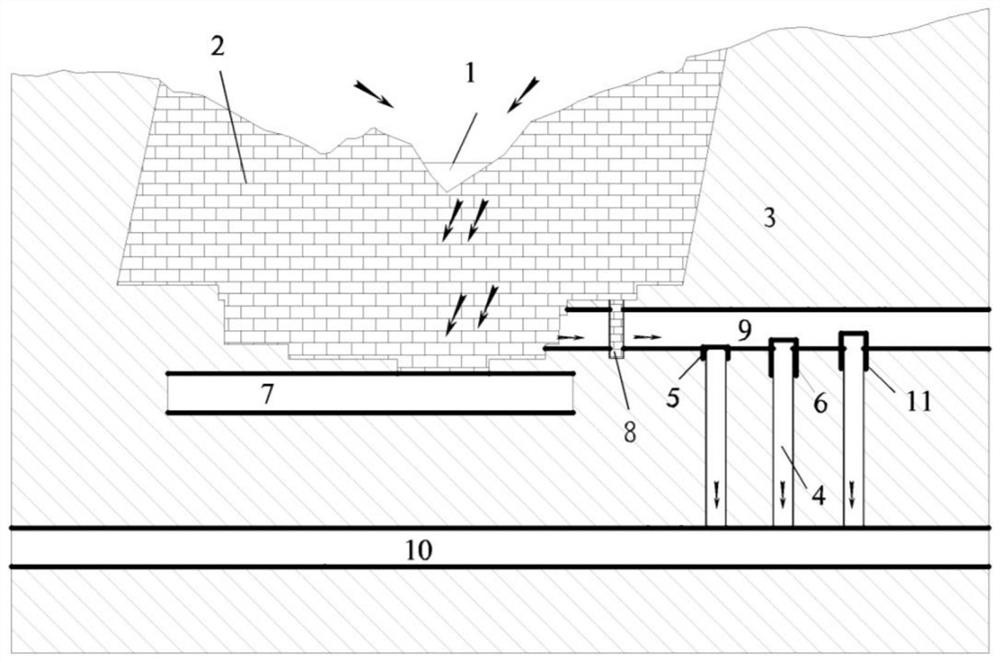

[0035] Embodiment 1: see figure 1 , figure 2 , a method for preventing and controlling water inrush in a goaf subsidence area by a bottomless pillar caving method, said method comprising the following steps:

[0036]Step 1: Use the Surpac 3D modeling software to establish the underground goaf area model and the original surface DTM model of the surface subsidence for less than 10 years, and then drop the subsidence boundary lines at different times on the original surface DTM model to obtain the subsidence of different years Boundary 3D model.

[0037] Step 2: Determine the central axis of the collapse; take the graphic center of the plane projection of the surface collapse boundary line as the plane projection point of the collapse center, and obtain the plane coordinates of the collapse central axis after converting the ACAD graphics of the collapse boundary line into a line file in the SURPAC environment , use SURPAC software line file to create the center point function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com