Medical waste incineration, filtration and purification equipment

A technology for filtering and purifying medical waste, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as inability to realize automation, disease spread, and harm to physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

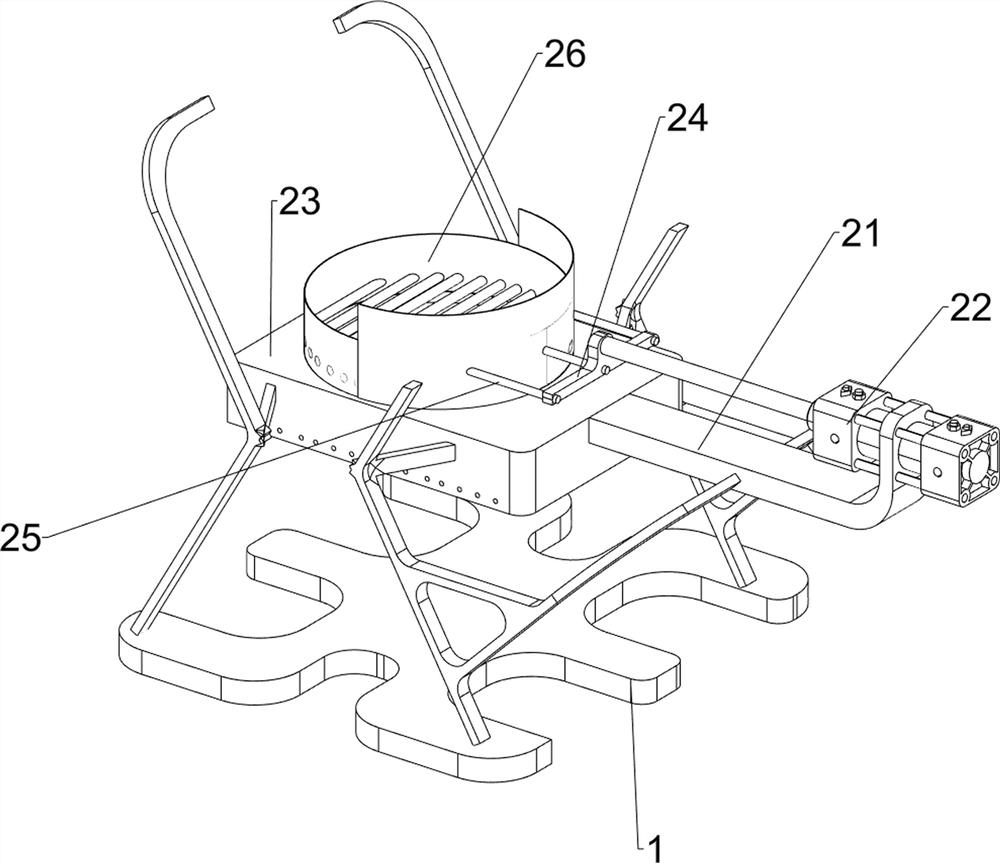

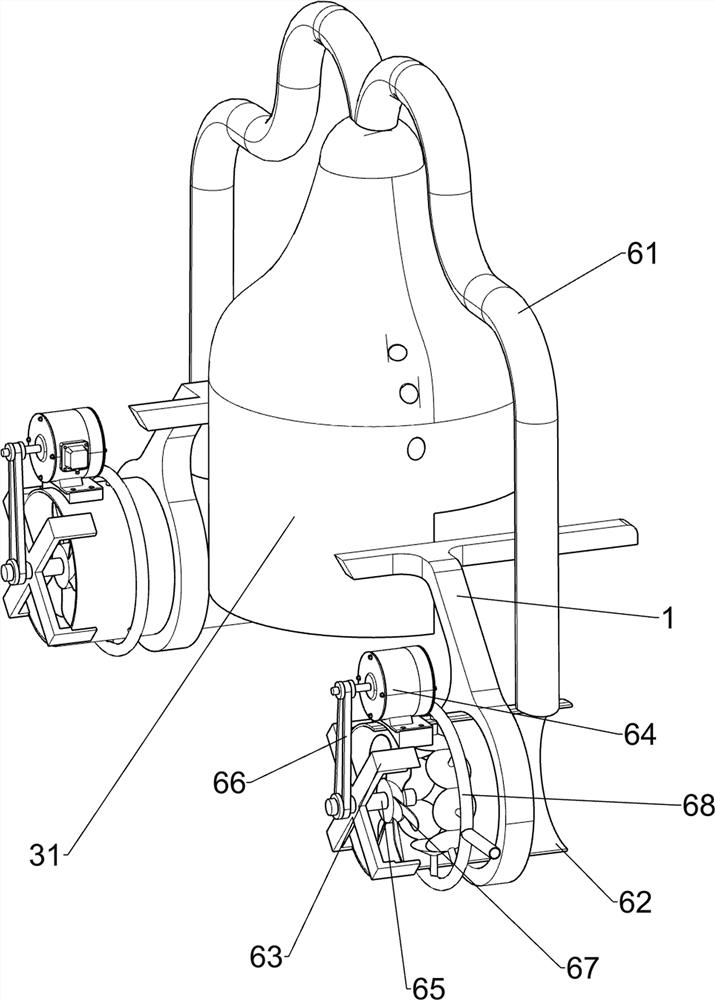

[0069] A medical waste incineration filter purification equipment, such as figure 1 with figure 2 As shown, a base frame 1, a material holding mechanism 2 and an incineration mechanism 3 are included.

[0070]When people need to incinerate medical waste, they can use this medical waste incineration filter purification equipment. First, people put the medical waste in the material holding mechanism 2, and then start the material holding mechanism 2, and the material holding mechanism 2 pushes the medical waste to the On the lower side of the incineration mechanism 3, the incineration mechanism 3 incinerates the medical waste, and closes the material holding mechanism 2 when pushing is not required.

Embodiment 2

[0072] On the basis of Example 1, such as image 3 with Figure 4 As shown, the material holding mechanism 2 includes a fixed plate 21, a cylinder 22, a mounting frame 23, a push block 24, a connecting column 25 and a hopper 26, the base frame 1 is connected with a mounting frame 23, and the mounting frame 23 rear portion is provided with a mounting plate 21. A cylinder 22 is installed at the rear of the fixed plate 21, and the telescopic rod of the cylinder 22 is connected with a push block 24. The front side of the push block 24 is evenly provided with three connecting columns 25, and the front part between the three connecting columns 25 is connected with a hopper 26 , The hopper 26 is slidably connected with the mounting frame 23 .

[0073] First, people put medical waste in the hopper 26, and then start the cylinder 22. The telescopic rod of the cylinder 22 drives the push block 24 and the connecting column 25 to reciprocate back and forth, thereby driving the hopper 26 ...

Embodiment 3

[0077] On the basis of Example 2, such as Figure 5-8 As shown, a fire valve mechanism 4 is also included. The fire valve mechanism 4 includes a first elastic assembly 41, a moving block 42, a top block 43, a slide bar 44 and a valve block 45. Top block 43, the upper side of the first fixed block 32 is slidingly provided with a first elastic assembly 41, the rear part between the two first elastic assemblies 41 is connected with a moving block 42, and the rear part of the moving block 42 cooperates with the front part of the top block 43 , The upper side of the middle part of the moving block 42 is provided with a slide bar 44, the rear part of the slide bar 44 is connected with a valve block 45, and the valve block 45 is slidably connected with the catheter tube 34 front side.

[0078] The reciprocating movement of the hopper 26 drives the top block 43 back and forth. When the hopper 26 drives the top block 43 to move forward to the bottom of the incinerator 31, the top block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com