Integrally-formed bent-swept combined blade, impeller and axial flow fan

A combined blade and integral molding technology, which is applied to axial flow pumps, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of reducing the aerodynamic performance of mine axial flow fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

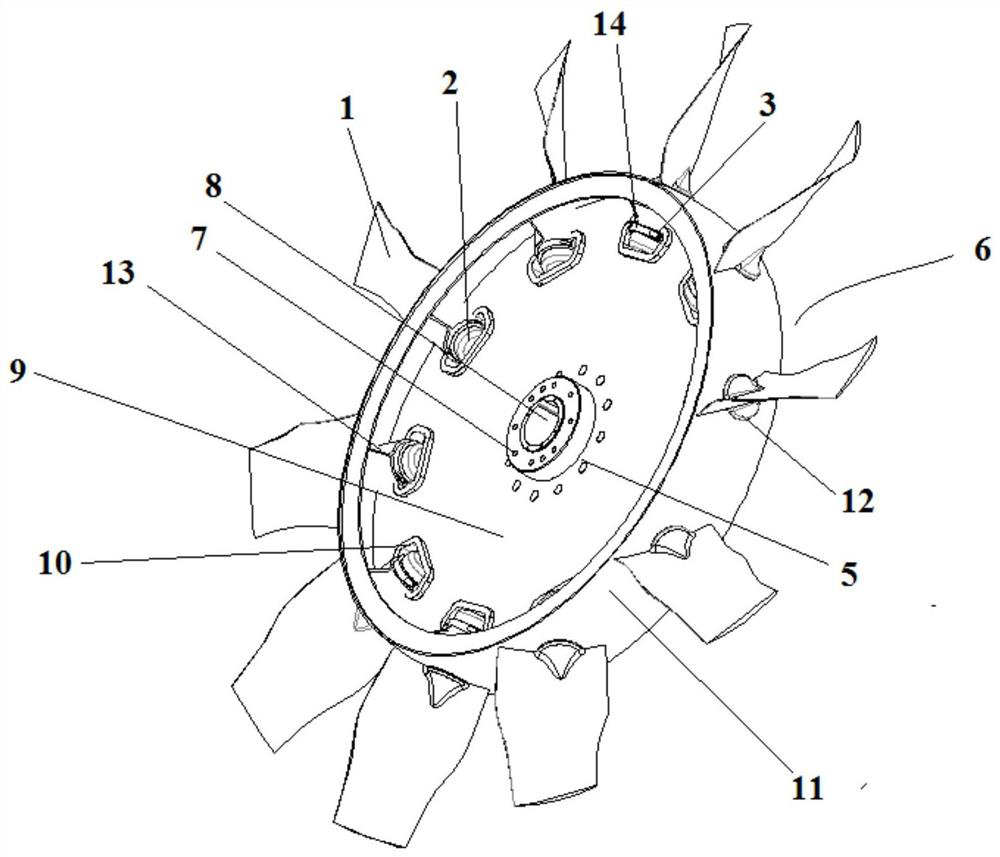

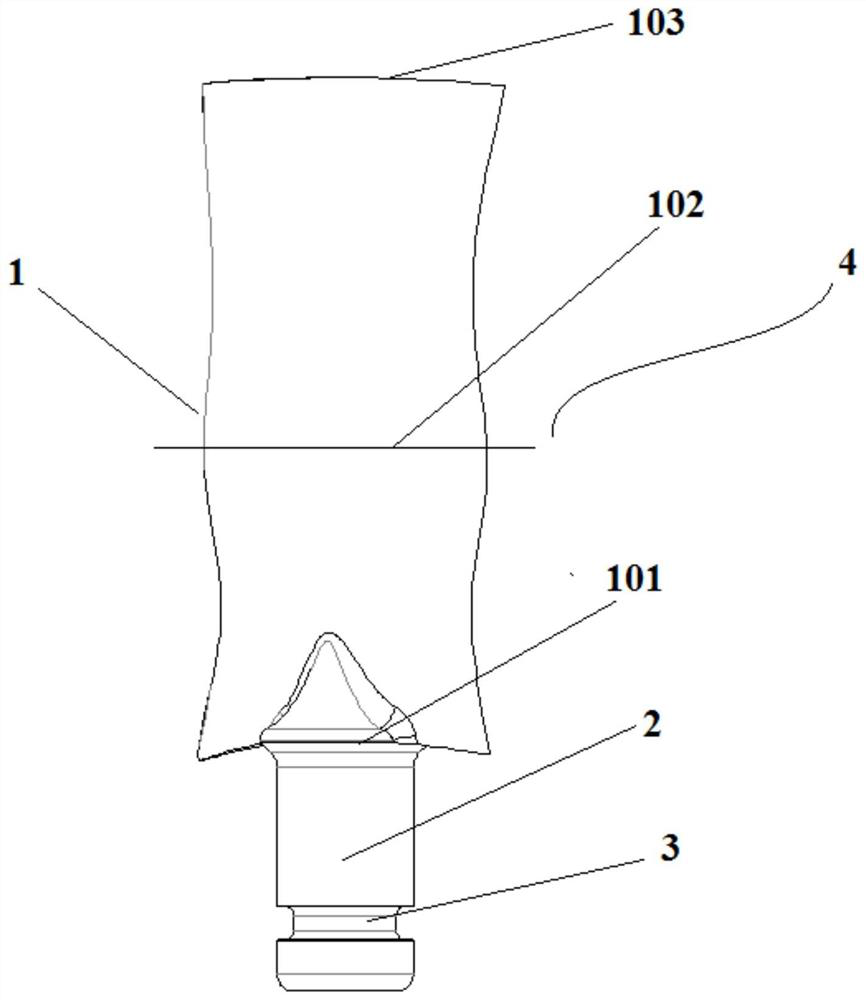

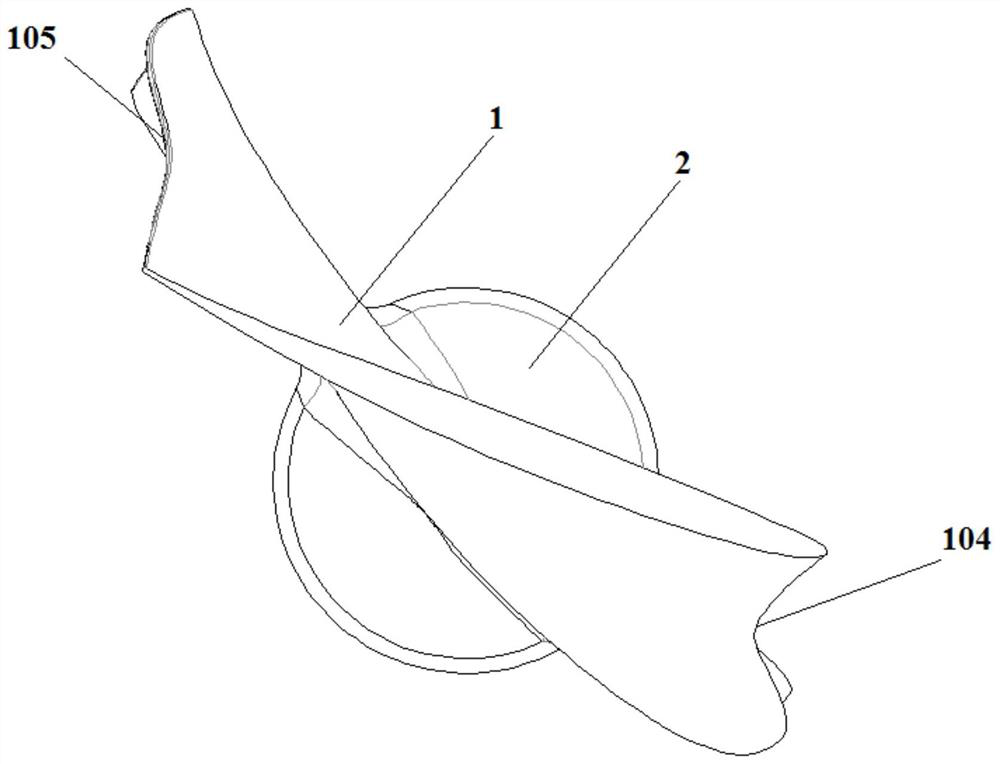

[0098] This embodiment provides an integrally formed curved and swept combined blade, such as Figure 1 to Figure 4 As shown, it includes an integrally formed blade body 1 and a petiole 2; the blade body 1 includes a blade body root 101, a blade body middle 102 and a blade body top 103; The center-of-gravity stacking line of the blade body 1 shape of the control curved-sweep combination blade 4 described above is a quadratic Bezier curve; wherein,

[0099] The center-of-gravity stacking line that controls the shape of the blade body 1 of the curved-swept combined blade 4 is projected in the circumferential plane as the blade forward bending control line, and an x-y plane Cartesian coordinate system is established in the circumferential plane, where x and y are the x-y plane Cartesian coordinates respectively The abscissa and ordinate in the system; in the x-y plane Cartesian coordinate system, take the intersection point of the center of gravity of the blade body root and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com