Intelligent track laying method and intelligent track laying equipment

An intelligent and equipped technology, applied in track laying, track, track maintenance, etc., can solve problems such as low operation efficiency, difficult quality control, and many operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

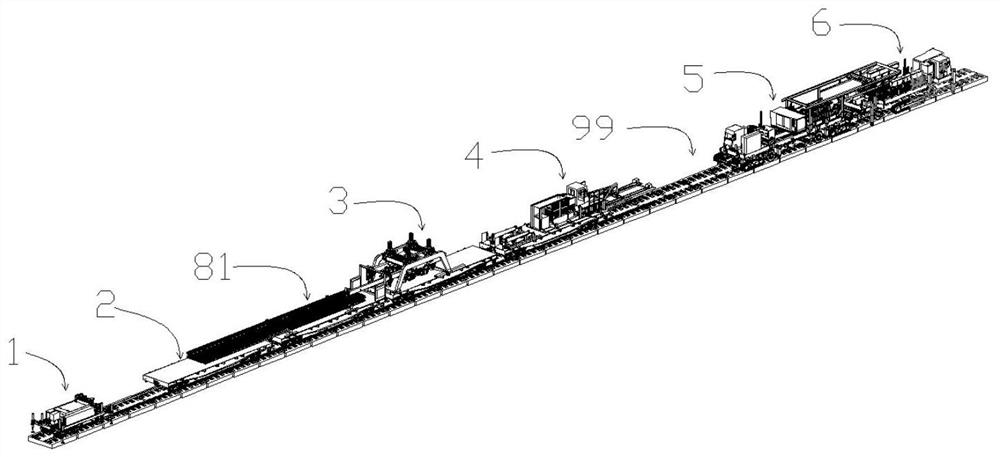

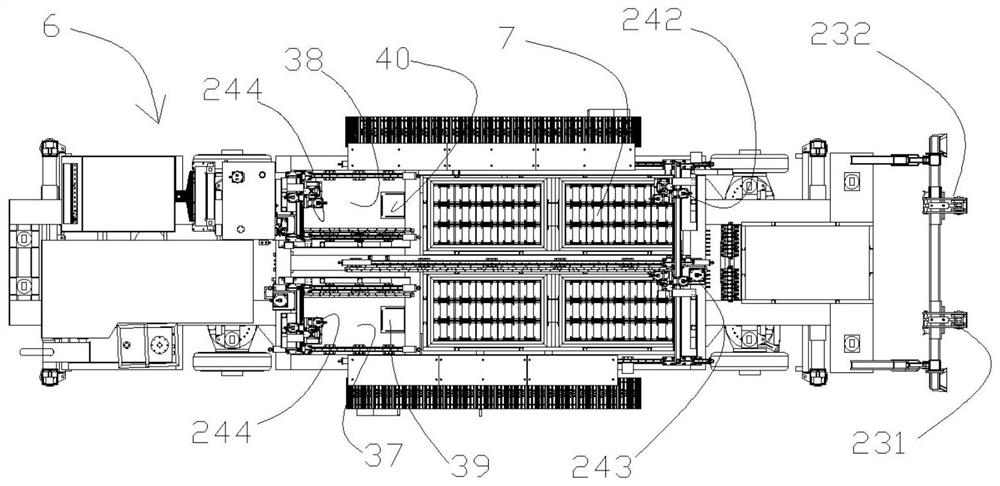

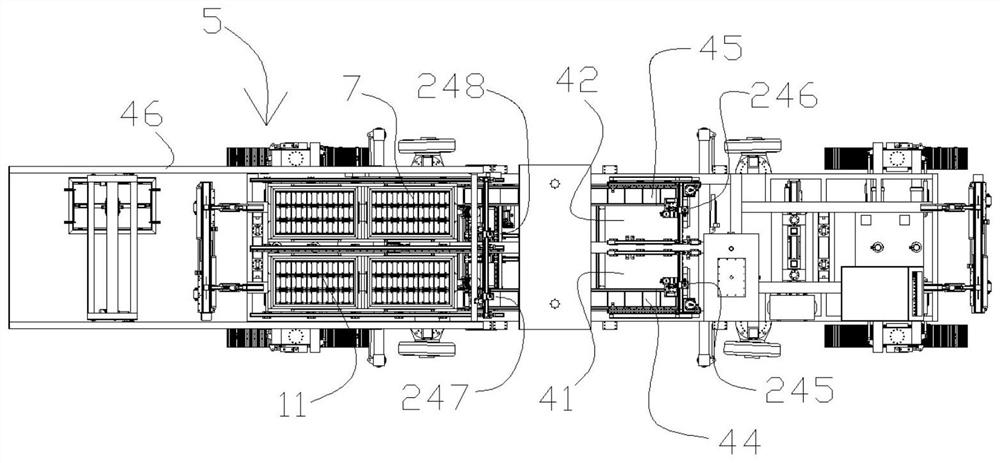

[0064] The present invention will be further described below in conjunction with accompanying drawing:

[0065] Such as Figure 20 As shown in -23, the present invention is applied to the laying of ballastless track of high-speed railway. The work done before includes: the sleeper has been installed according to the set position on both sides of the ballastless bed; Iron backing plate 90, gauge baffle plate, under-rail fine-tuning backing plate, and under-rail backing plate have been installed, and spring bar 96 and spike 98 have been pre-installed informally.

[0066] Since the accessories of the sleeper have been pre-assembled, the sleeper is referred to as a pre-installed sleeper 89 hereinafter.

[0067] The work objects associated with the present invention include steel rails 81 , pre-installed sleepers 89 , iron backing plates 90 , spring bars 96 and spikes 98 .

[0068]Rail 81: the rail head 82 located on the upper part of the rail, the rail bottom 85 located at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com