A sewage purification device

A sewage purification and push device technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem that solid impurities in the filter screen cannot be automatically removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

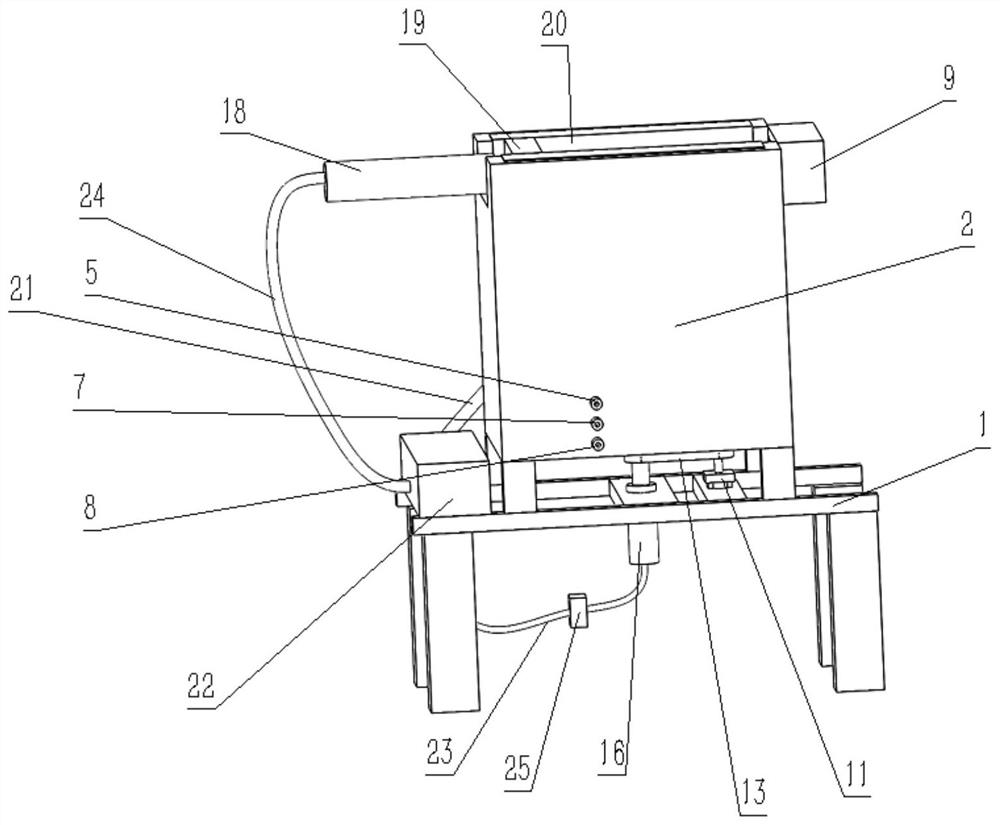

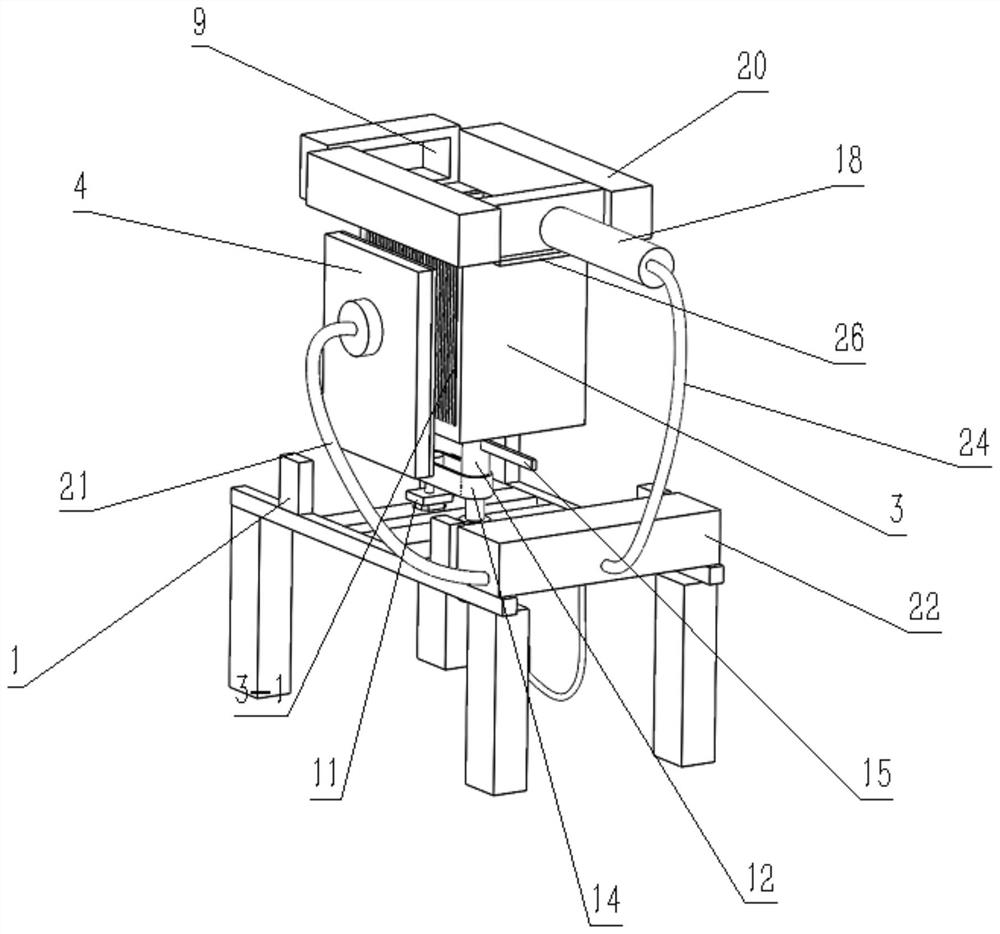

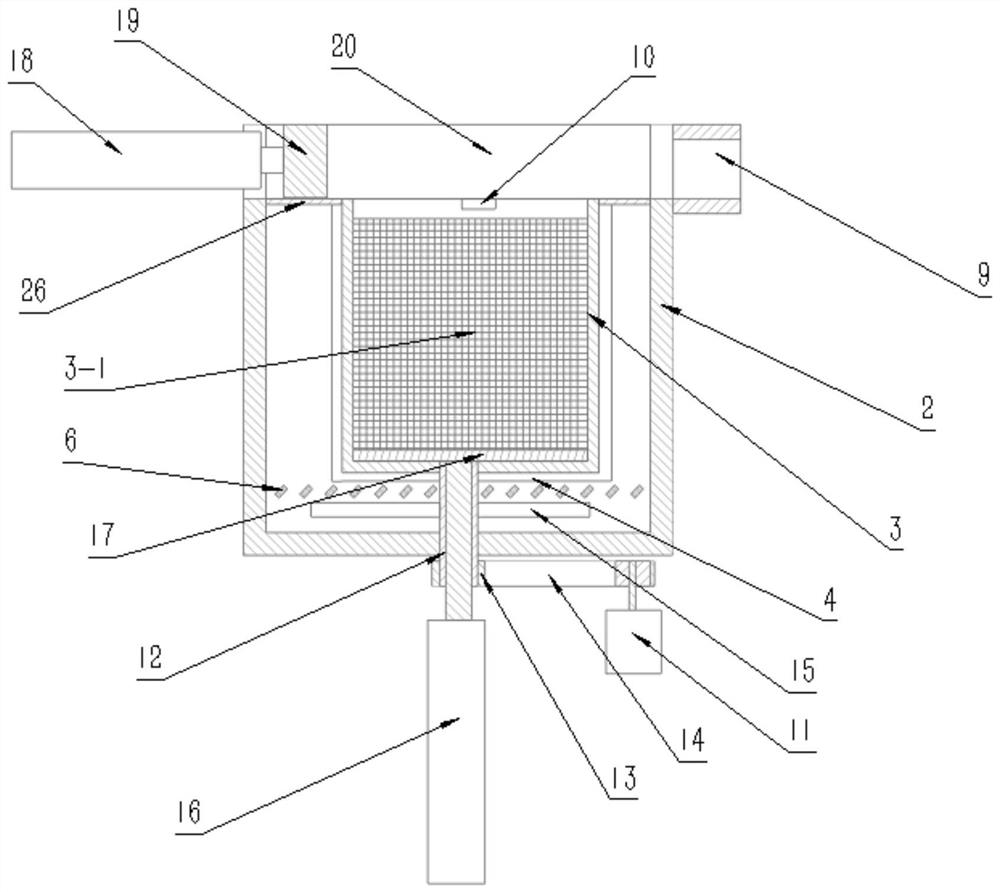

[0026] see Figure 1-3 , a sewage purification device, comprising a frame body 1, a water storage container 2 with an upward opening is arranged on the frame body 1, and a filter box 3 with an upward opening and a filter screen 3-1 on one side is arranged in the water storage container 2 , the inner bottom wall of the filter box 3 is provided with a vertical solid impurity pushing device, and the water storage container 2 is provided with a horizontal solid impurity pushing device that cooperates with the vertical solid impurity pushing device at the opening of the filter box 3, The side wall of the water storage container 2 is provided with an air plate 4 corresponding to the filter screen 3-1. The side wall of the water storage container 2 is sequentially provided with a clean water outlet 5 and a sloping plate below the filter box 3. 6. A drug injection pipe 7 with an on-off valve, an emptying valve 8, and a stirring device under the filter box 3 in the water storage contai...

Embodiment 2

[0029] see Figure 1-3 , a sewage purification device, comprising a frame body 1, a water storage container 2 with an upward opening is arranged on the frame body 1, and a filter box 3 with an upward opening and a filter screen 3-1 on one side is arranged in the water storage container 2 , the inner bottom wall of the filter box 3 is provided with a vertical solid impurity pushing device, and the water storage container 2 is provided with a horizontal solid impurity pushing device that cooperates with the vertical solid impurity pushing device at the opening of the filter box 3, The side wall of the water storage container 2 is provided with an air plate 4 corresponding to the filter screen 3-1. The side wall of the water storage container 2 is sequentially provided with a clean water outlet 5 and a sloping plate below the filter box 3. 6. A drug injection pipe 7 with an on-off valve, an emptying valve 8, and a stirring device under the filter box 3 in the water storage containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com