Welding processing technology for copper pipe of air conditioner condenser

An air-conditioning condenser and processing technology technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of cumbersome operation engineering and the safety of operators cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

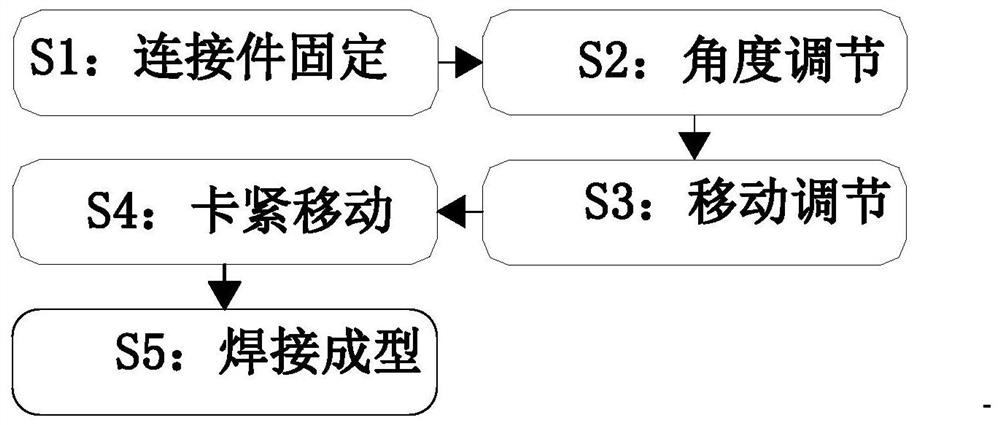

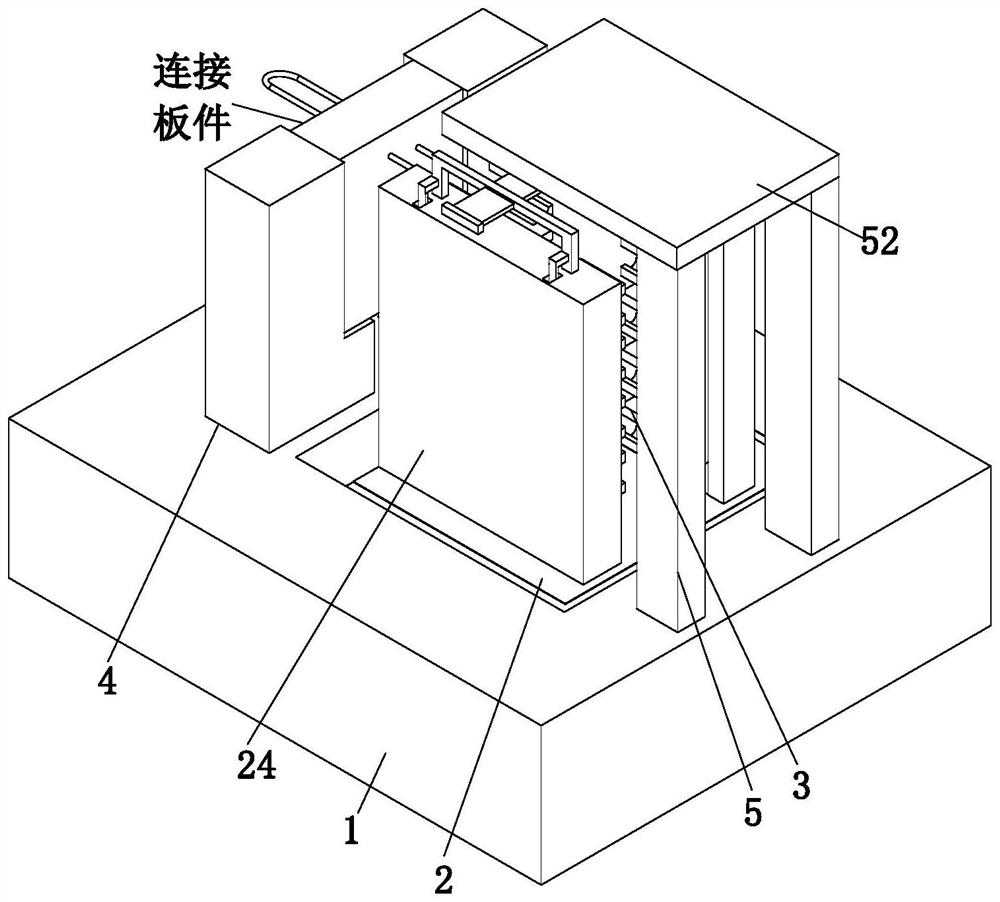

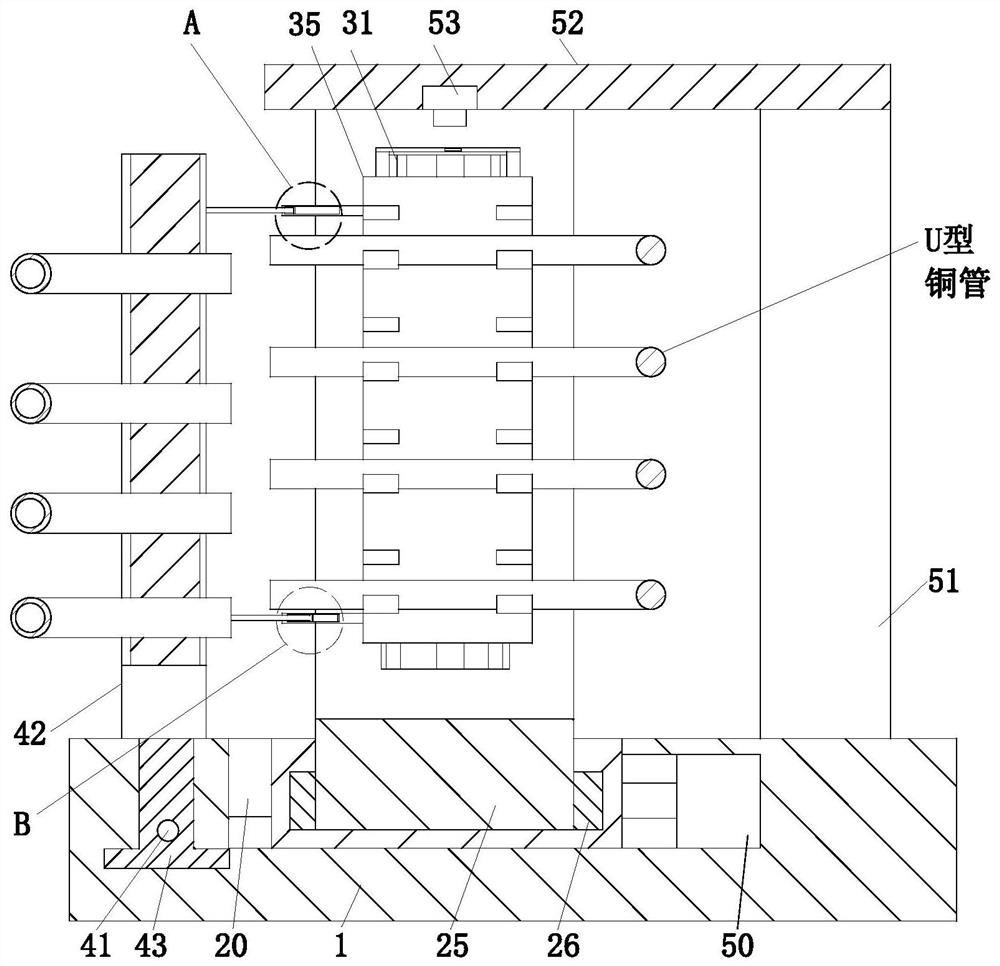

[0035] Such as Figure 1 to Figure 9 As shown, a copper tube welding process for an air conditioner condenser uses a copper tube welding process device for an air conditioner condenser. , Fixing mechanism 4 and pushing mechanism 5, when adopting above-mentioned air-conditioning condenser copper pipe welding processing device to carry out welding processing, specific processing technology is as follows:

[0036] S1. Connector fixation: fix the condenser copper tube connector plate through the fixing mechanism 4;

[0037] S2. Angle adjustment: after step S1, place the U-shaped copper tube in the arc-shaped groove of the front and rear No. 1 slot plate 37, and adjust the placement angle of the U-shaped copper tube according to the condenser copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com