Multi-station high-flux pipetting equipment

A high-throughput, multi-station technology, applied in the direction of measuring tubes/pipettes, laboratory utensils, laboratory containers, etc., can solve the deformation of supporting mechanisms, skewing of pipetting components, Liquid tip insertion failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

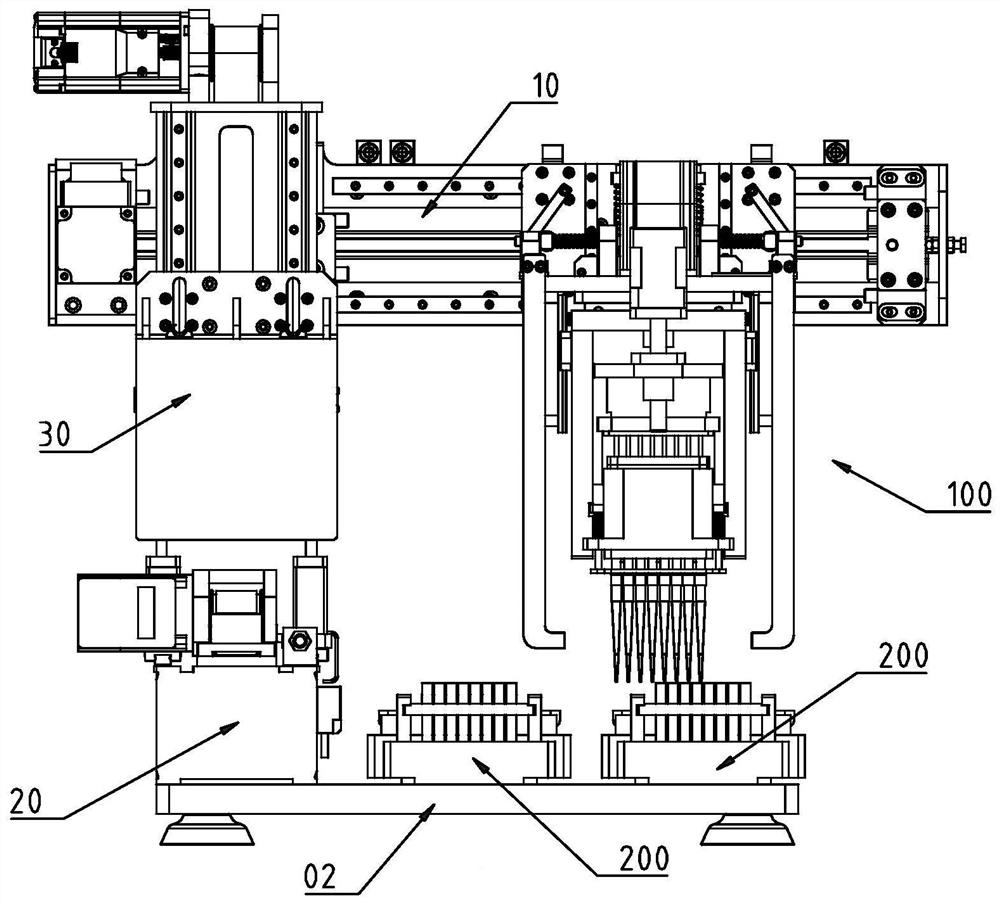

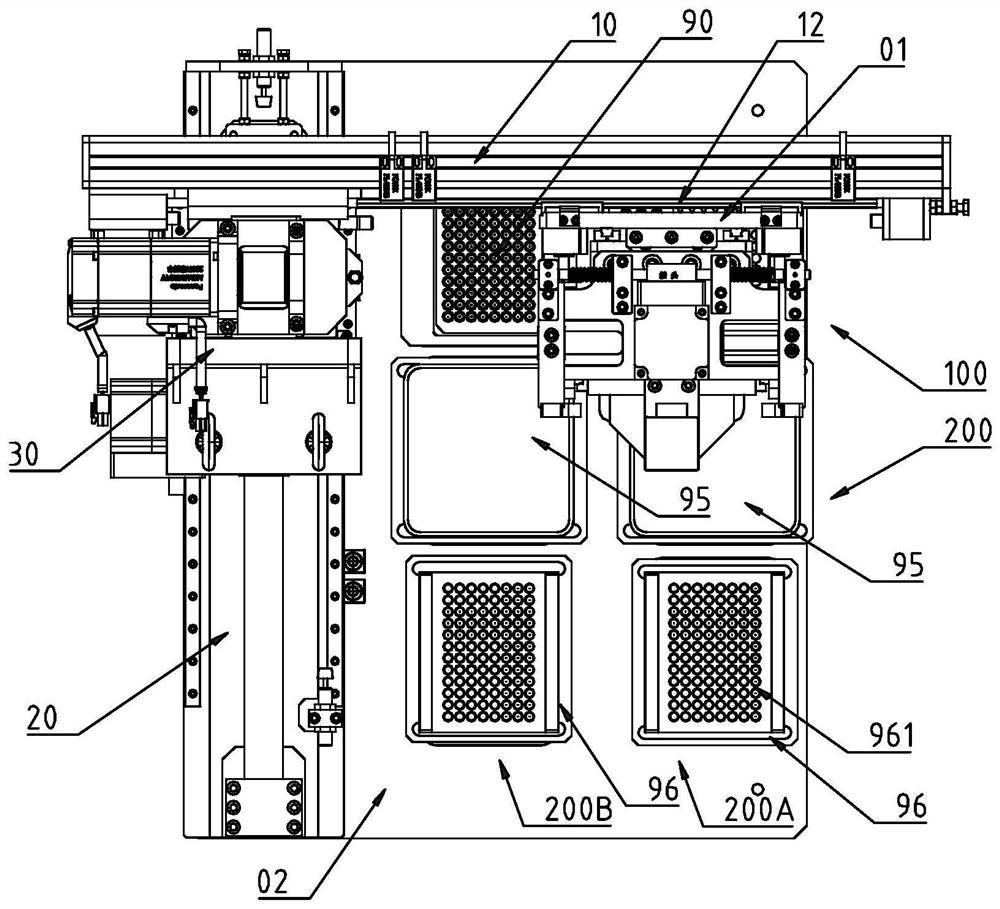

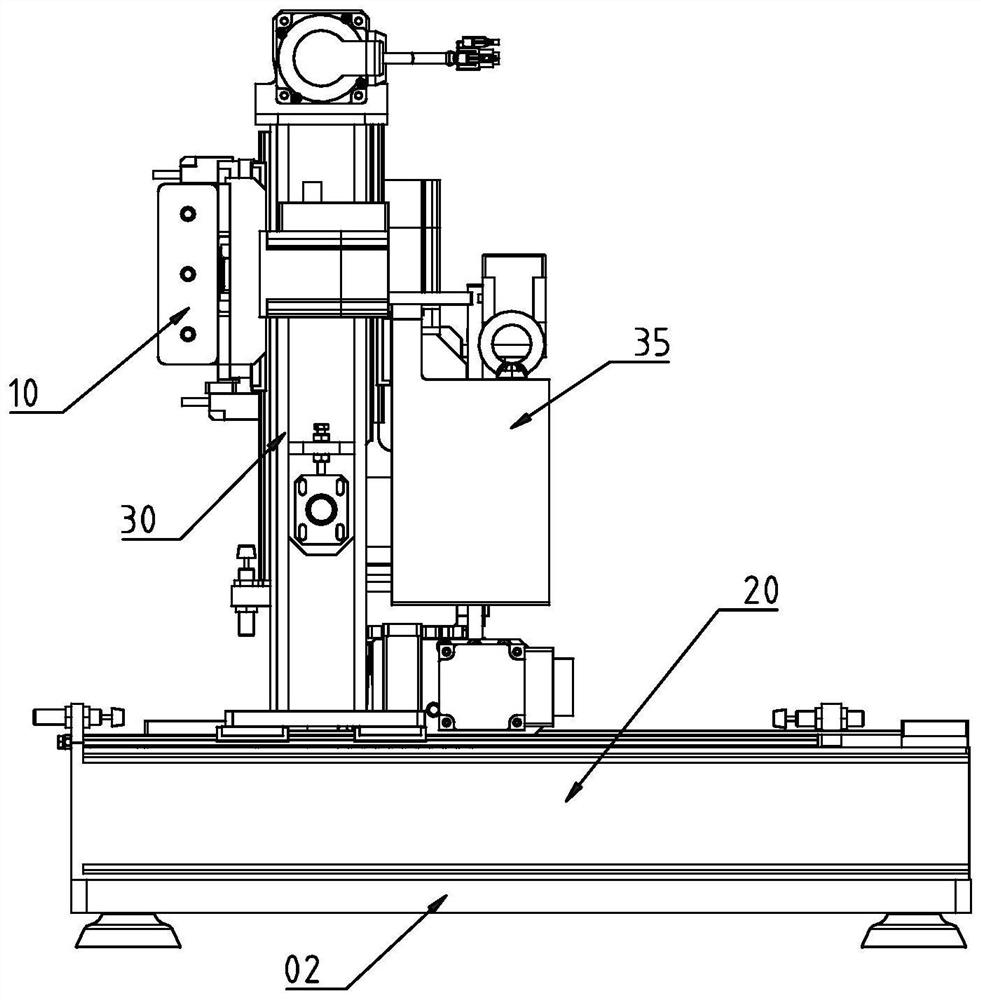

[0048] The structure of the multi-station high-throughput pipetting device in the embodiment of the present invention is as follows: Figure 1 to Figure 20 As shown, it includes a base 02, an X-axis driving mechanism 10, a Y-axis driving mechanism 20, a Z-axis driving mechanism 30, a pipetting head 100 and two columns of pipetting instruments 200. The pipetting head 100 includes a pipetting mechanism and an insertion mechanism. Each row of pipetting instruments 200 includes a pipetting tip box 90 , a liquid sample box 95 and a test tube box 96 .

[0049] The Y-axis driving mechanism 20 includes a linear module, and the linear module of the Y-axis driving mechanism 20 is installed on the base 02 along the Y-axis direction. It includes a housing 21, a Y-axis motor 22, a synchronous belt drive, a driving block 23 and two sets of linear guide rail pairs 24. The driving block 23 is arranged above the bar-shaped housing 21 and is a hollow structure, including two side plates 231 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com