Amorphous alloy catalyst for hydrogenating cyclobufene sultone and its prepn. and application

An amorphous alloy, sulfolane technology, applied in the preparation of organic compounds, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of unsafe use of skeleton nickel, environmental pollution, etc., and achieve easy industrial scale-up The effect of production, no pollution, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

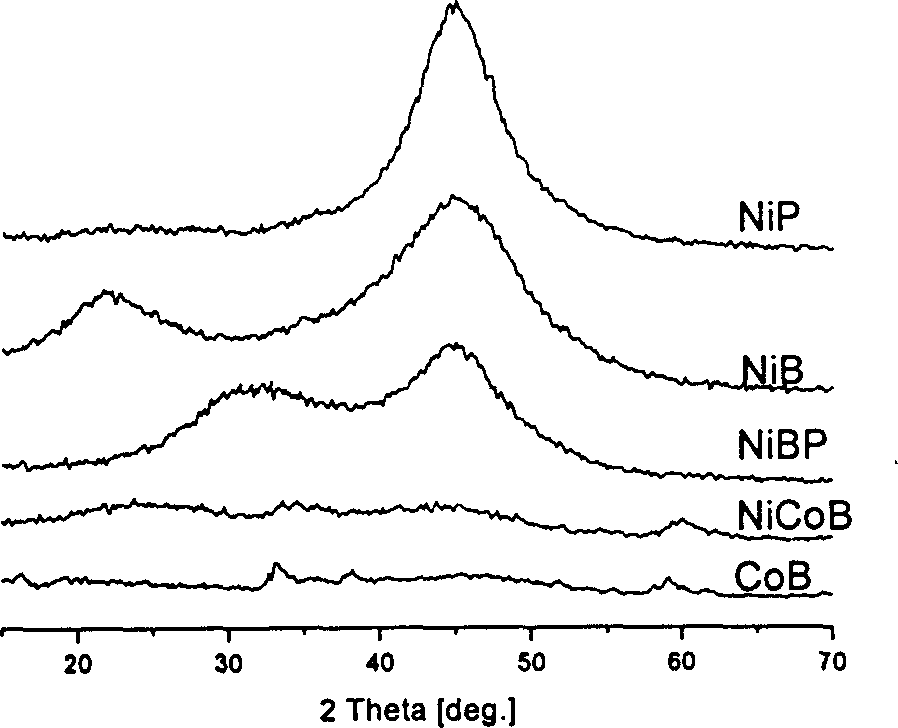

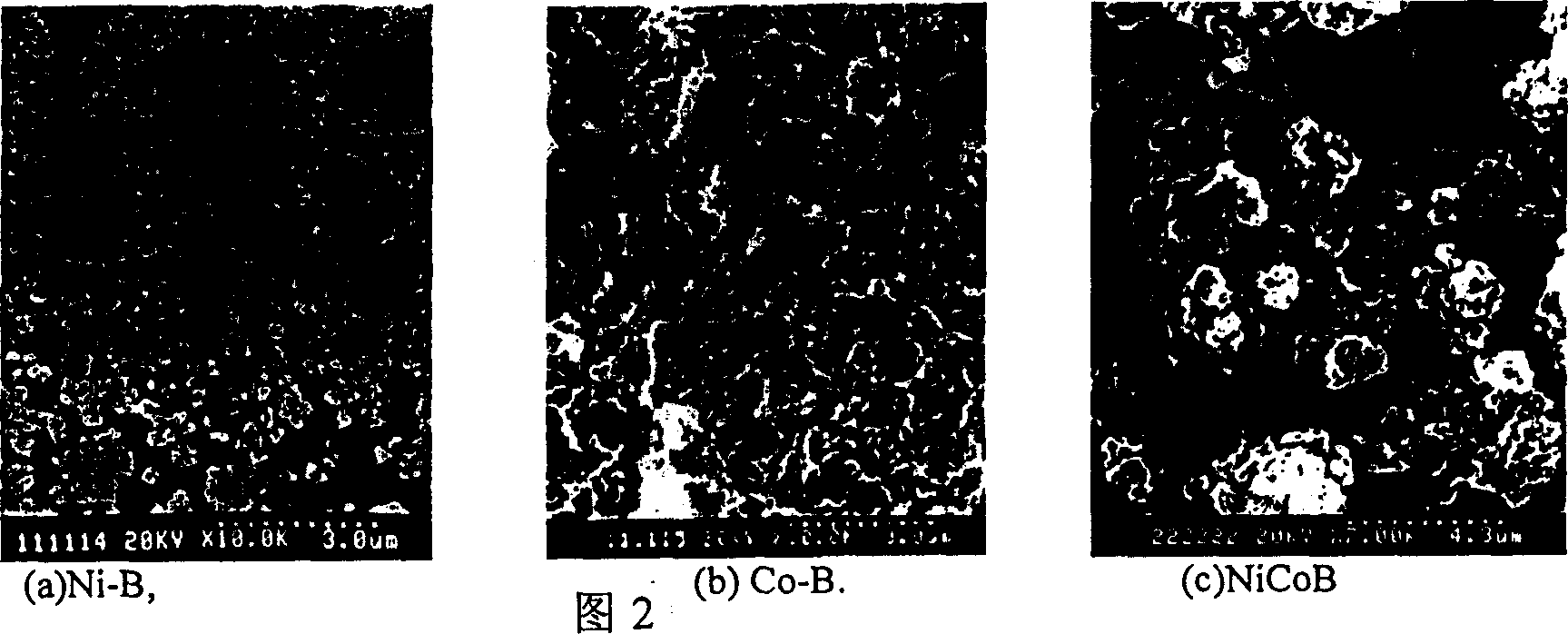

[0015] 268K, under the protection of nitrogen, add nickel nitrate solution (85ml, 0.4mol / l) dropwise to KBH at a speed of 6ml / min 4 (60ml) solution. After the reaction, centrifuge, wash with water until neutral, and then protect in ethanol. In its X-ray diffraction pattern (Figure 1), a broadened diffuse peak appears near 2θ=45°, which is the characteristic diffraction peak of NiB amorphous alloy, indicating that the synthesized NiB alloy is indeed amorphous. The broadened diffuse peak around 2θ=22° belongs to the characteristic peak of amorphous metalloid B. The scanning electron microscope (Fig. 2a) shows that the NiB amorphous alloy particles are approximately spherical, with an average particle size of about 15nm. Product atomic composition: Ni 69 B 31 .

[0016] The present invention uses a 250ml high-pressure reactor to carry out the sulfolene hydrogenation reaction. Reaction conditions: ratio of sulfolene to catalyst 10-1; hydrogen pressure 3MPa; reaction temperat...

Embodiment 2

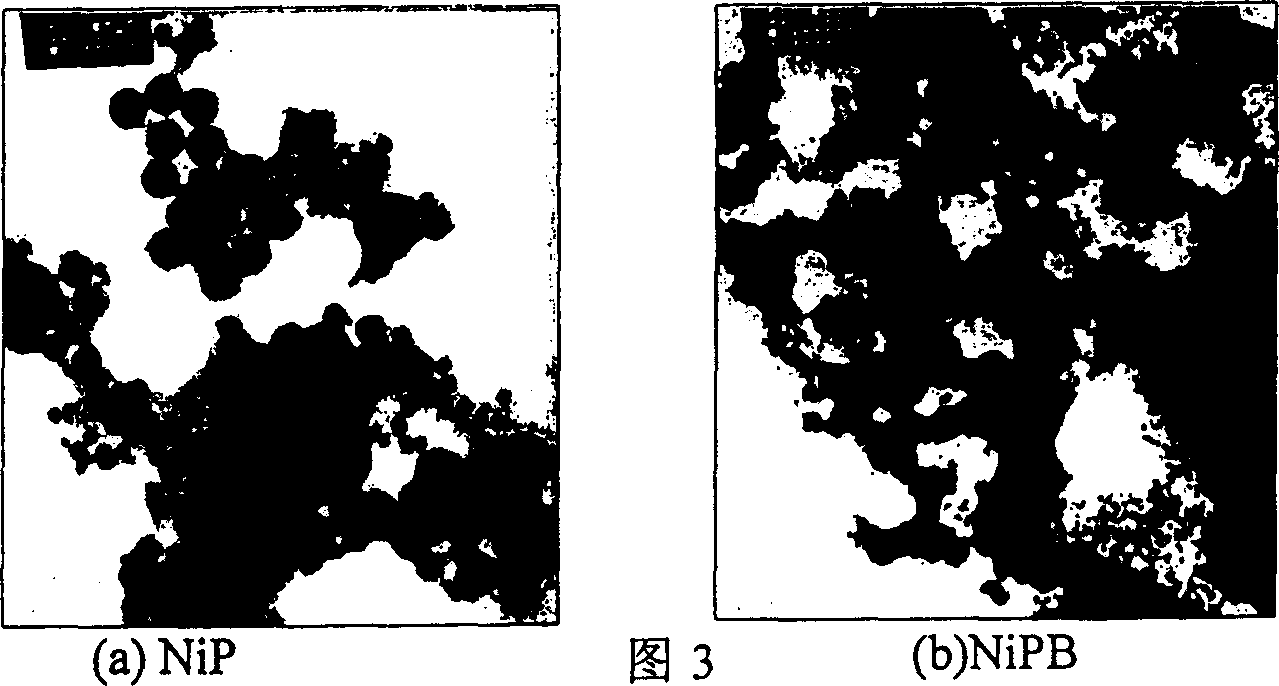

[0018] Add 24 grams of nickel hypophosphite, 2 grams of sodium acetate, and 4 grams of sodium citrate into 100 ml of distilled water at 300K, and adjust the pH of the solution to 7-8 with sodium hydroxide. Add a few drops of KBH while stirring 4 The solution initiates the reaction. The product was centrifuged, washed with water until neutral, and placed in ethanol for protection. In its X-ray diffraction pattern (Figure 1), a broadened diffuse peak appears near 2θ=45°, which is the characteristic diffraction peak of NiP amorphous alloy, indicating that the synthesized NiP alloy is indeed amorphous. The transmission electron microscope image (Fig. 3a) shows that the NiP amorphous alloy particles are spherical, with an average particle size of about 30nm. Product atomic composition: Ni 65 P 35 .

[0019] The reaction conditions are the same as in Example 1.

Embodiment 3

[0021] KBH under 300K 4 The solution (26ml) was dripped into the nickel hypophosphite solution (50ml, 1mol / l) at a rate of 0.9ml / min. The product was centrifuged, washed with water until neutral, and placed in ethanol for protection. In its X-ray diffraction pattern (Figure 1), a broadened diffuse peak appears near 2θ=45°, which is the characteristic diffraction peak of NiPB amorphous alloy, indicating that the synthesized NiPB alloy is indeed amorphous. Transmission electron microscopy (Figure 3b) shows that NiPB particles are irregular in shape, with an average particle size of about 20nm, which is between NiP and NiB. Product atomic composition: Ni 69 B 20 P 11 .

[0022] The reaction conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com