Fault detection method and device for a special motor

A special motor and fault detection technology, applied in the direction of measuring devices, motor generator testing, measuring electricity, etc., can solve the problem of inaccurate fault diagnosis and achieve the effect of accurate fault diagnosis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

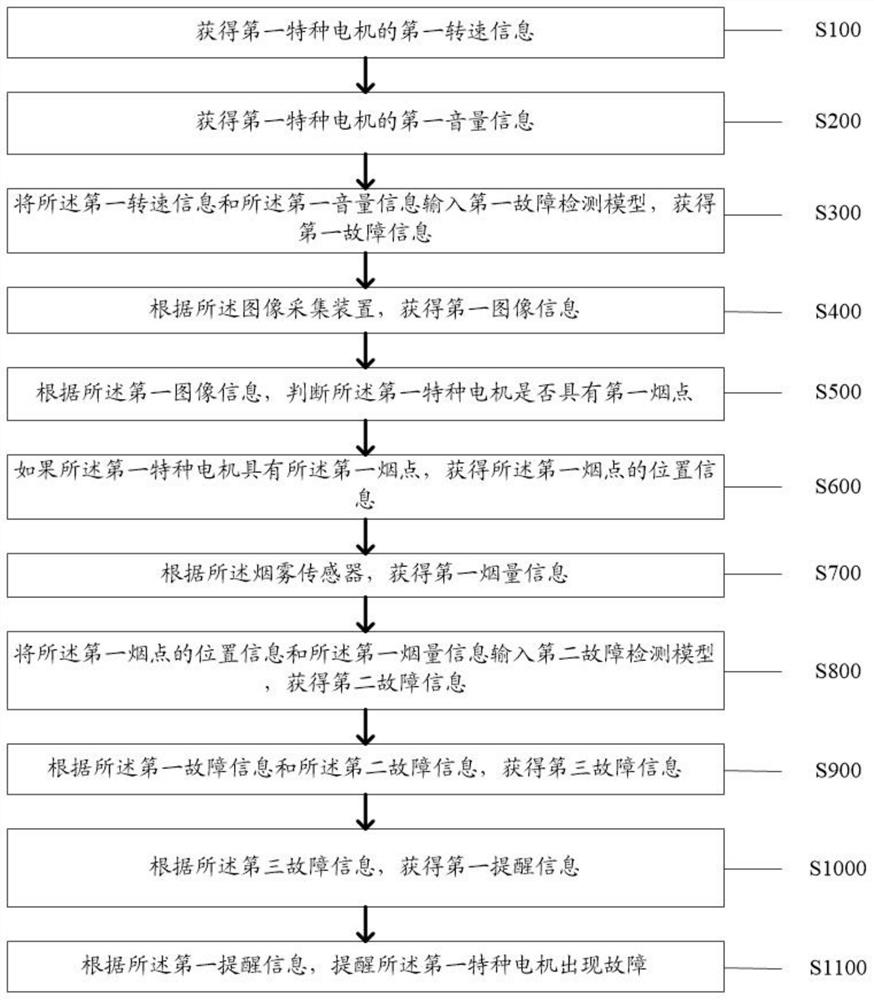

[0024] Such as figure 1 As shown, the embodiment of the present application provides a fault detection method for a special motor, wherein the method is applied to a fault detection device for a special motor, and the device includes an image acquisition device and a smoke sensor. The method include:

[0025] Step S100: Obtain the first rotational speed information of the first special motor;

[0026] Specifically, the fault detection device is a device for fault diagnosis and detection of special motors, the image acquisition device is a device that can collect images of motors, and the smoke sensor is a sensor that can detect the amount of smoke , the first rotational speed information is the current rotational speed information of the first special motor.

[0027] Step S200: Obtain the first volume information of the first special motor;

[0028] Specifically, the volume information is the volume information generated by the first special motor when it is working, and th...

Embodiment 2

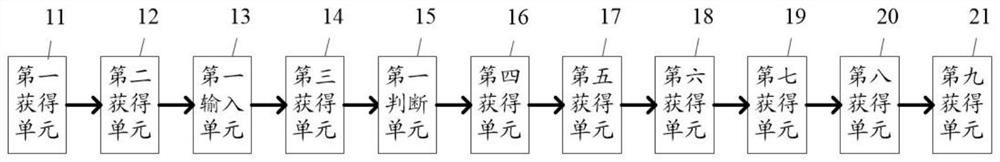

[0088] Based on the same inventive concept as the fault detection method of a special motor in the foregoing embodiments, the present invention also provides a fault detection device for a special motor, such as figure 2 As shown, the device includes:

[0089] A first obtaining unit 11, the first obtaining unit 11 is used to obtain the first rotational speed information of the first special motor;

[0090] A second obtaining unit 12, the second obtaining unit 12 is used to obtain the first volume information of the first special motor;

[0091] A first input unit 13, configured to input the first rotational speed information and the first volume information into a first fault detection model to obtain first fault information;

[0092] A third obtaining unit 14, the third obtaining unit 14 is configured to obtain the first image information according to the image acquisition device;

[0093] A first judging unit 15, configured to judge whether the first special motor has a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com