Chemical storage device with damping function based on chemical production

A technology for chemical production and storage devices, used in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve problems such as difficulty, reinforcement, and liquid seepage at the cover plate, to improve unit elastic strength and improve buffering. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

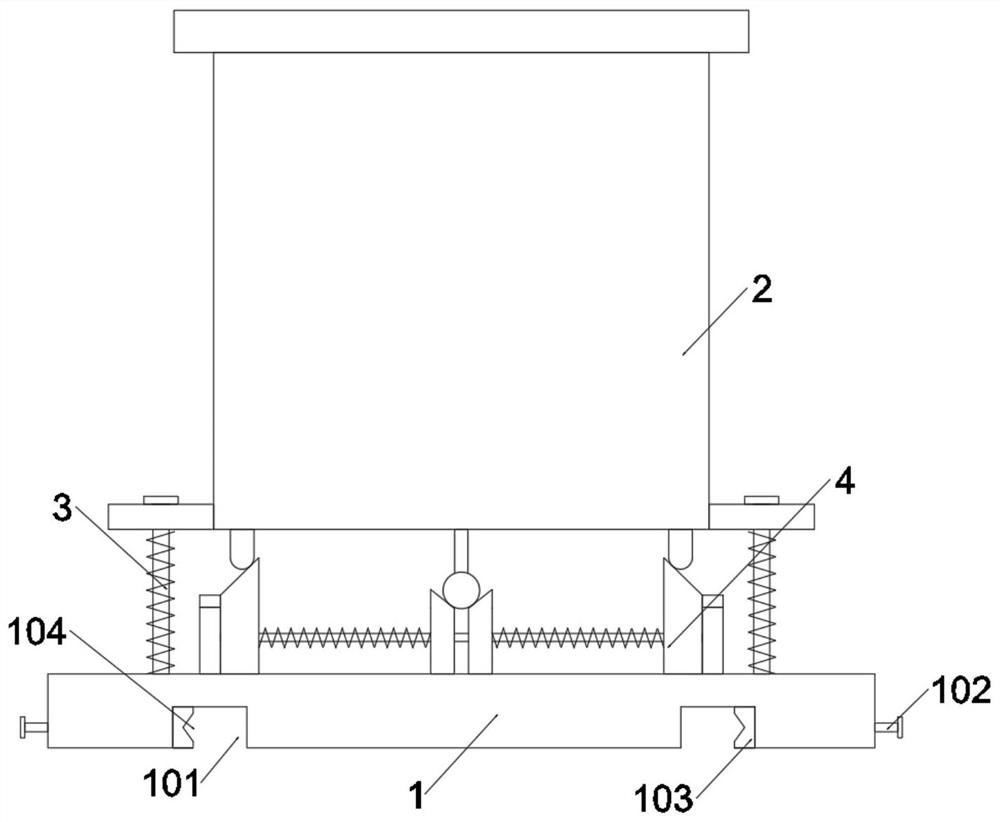

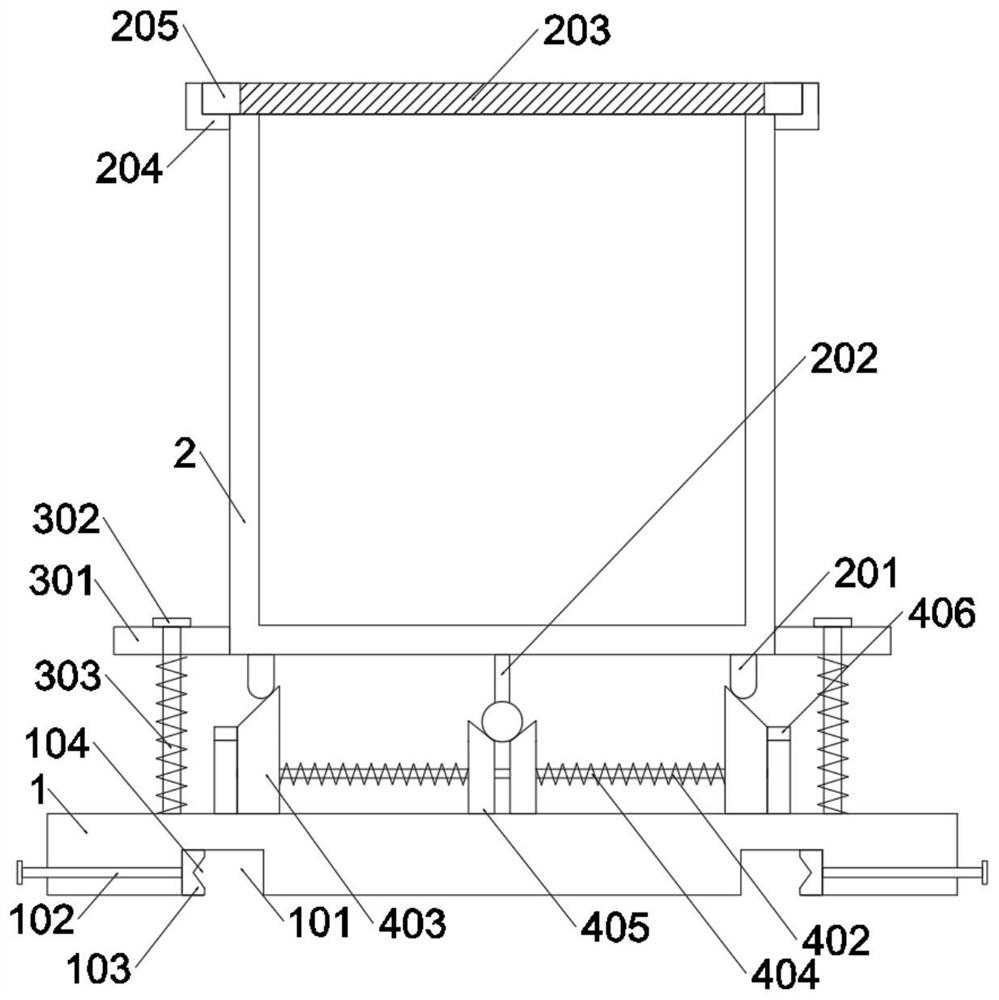

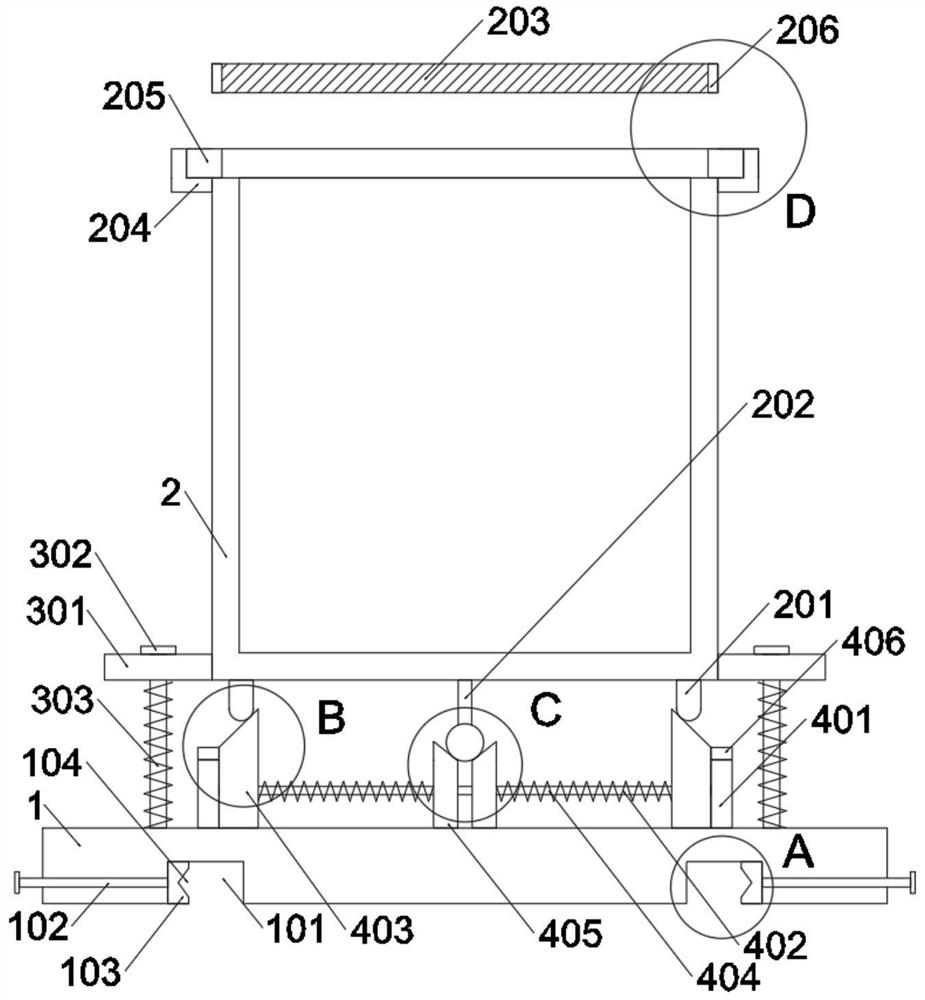

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The invention provides a chemical storage device with a shock-absorbing function based on chemical production, including a base 1; a buffer structure 3 is installed on the base 1, and a storage bucket 2 is installed on the buffer structure 3, and a shock-absorbing Structure 4; refer to eg image 3 with Figure 5 The storage bucket 2 includes a toggle block A201, two toggle blocks A201 are symmetrically welded on the bottom surface of the storage bucket 2, and the toggle block A201 is in contact with the top surface of the force-bearing block A403, and the top surface of the force-bearing block A403 is an inclined structure , so that when the toggle block A201 moves downwards following the storage bucket 2, buffering and shock absorption can be achieved by elastically squeezing the toggle block A201; refer to image 3 with Image 6 , the shock absorbing structure 4 includes a force-bearing block B405, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com