Production process and production line of steel bar truss laminated slab

A steel truss and production process technology, applied in the field of steel truss composite panel production process and production line, can solve the problems of incapable of maximizing the release of production capacity, low efficiency, long production line production cycle, etc., to shorten the production cycle, reduce the number of times, improve the The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

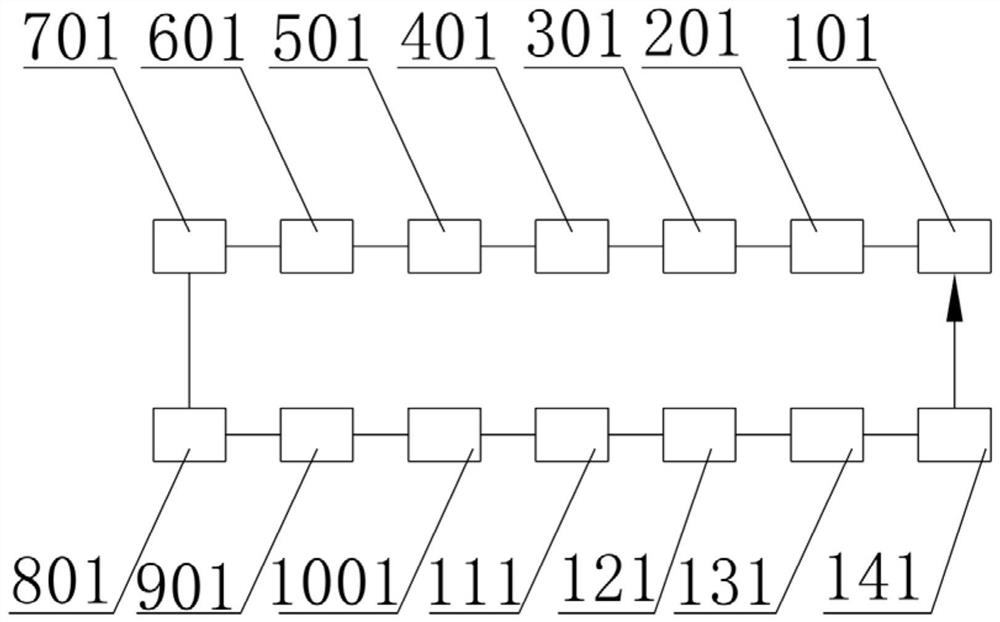

[0025] refer to figure 1 and figure 2 , a steel truss laminated plate production process, comprising the following steps:

[0026] Process 1 101: Molds and trolleys are cleaned. Molds and trolleys are recycled. A set of molds and trolleys travel between the entire production line, so molds and trolleys will leave the upper group of laminated plates during production. Residual concrete residue. At this time, it is necessary to remove the concrete residue on the mold and trolley with long and short flat shovels at one time. There are some small residues that are difficult to remove with a flat shovel. At this time, a hand-held broom is required to clean the remaining dust on the trolley; in order to ensure that the surface of the mold and the trolley is clean, the mold and the trolley should be thoroughly cleaned with compressed air ;

[0027] Process 2 201: Mold assembly, after the mold and the trolley are cleaned, the preparation for pouring is to be carried out. Firstly, ...

Embodiment 2

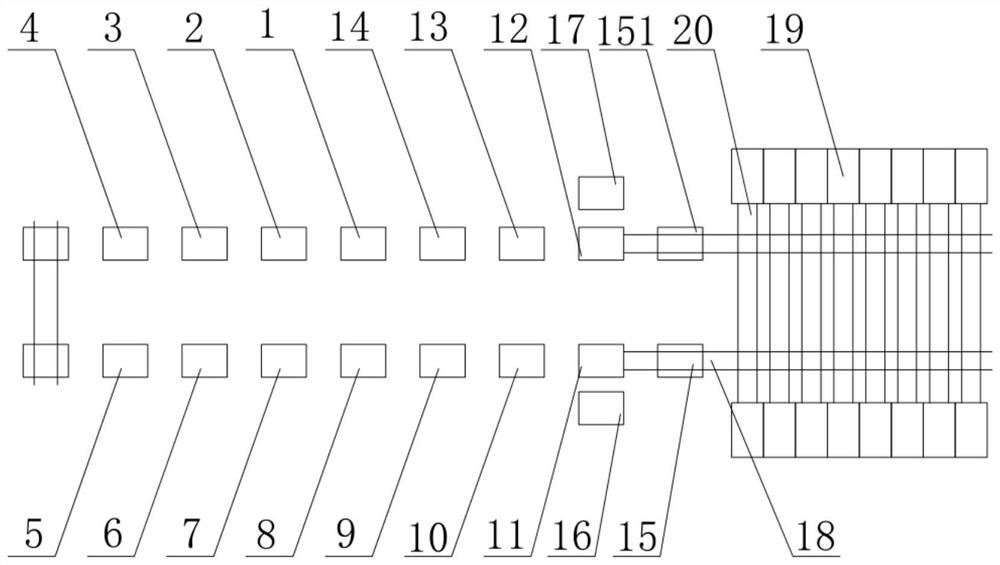

[0041] This embodiment provides a steel truss laminated slab production line that implements the steel truss laminated slab production process in Embodiment 1.

[0042] refer to figure 1 and figure 2 , the steel bar truss laminated board production line includes a curing kiln 19, a plate lowering machine 17, a first transfer rail car 15, a second transfer rail car 151, a trolley, a running track 18, a plate lifting machine 16, and station one 1, work Station Two 2, Station Three 3, Station Four 4, Station Five 5, Station Six 6, Station Seven 7, Station Eight 8, Station Nine 9, Station Ten 10, Station Eleven 11, Station 12 12, Station 13 13, and Station 14 14, wherein, the lowering machine 17 and the lifting machine 16 are fixed at designated positions, and the first transfer rail car 15 and the second transfer rail car 151 are both in operation. on track 18.

[0043] Among them, process one 101 to process seven 701 correspond to station one 1 to station seven 7 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com