Chain type driving telescopic arm

A telescopic arm and chain-type technology, which is applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve the problems of high processing precision requirements, small application range, and simple overall structure, so as to reduce equipment and use costs and ensure independence. Sex and tightness, the overall structure is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present application will be described in detail below in conjunction with specific embodiments.

[0030] This application relates to a chain-driven telescopic arm, which is mainly used as a drive structure for linear motion in the vertical direction, and is used for various mechanical processing, especially for shot blasting, painting, etc., which have sealing requirements, and the mechanical arm is easily damaged. In case of contamination by foreign substances.

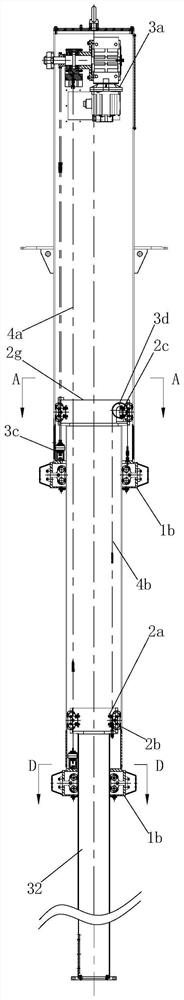

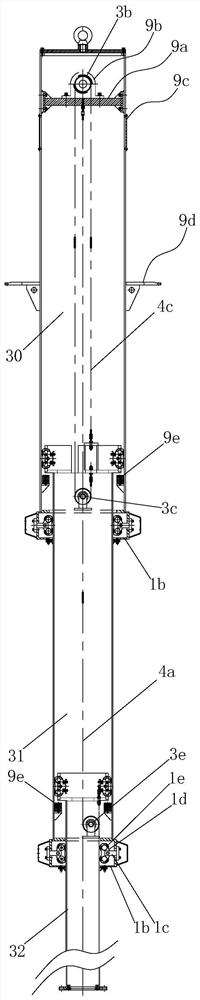

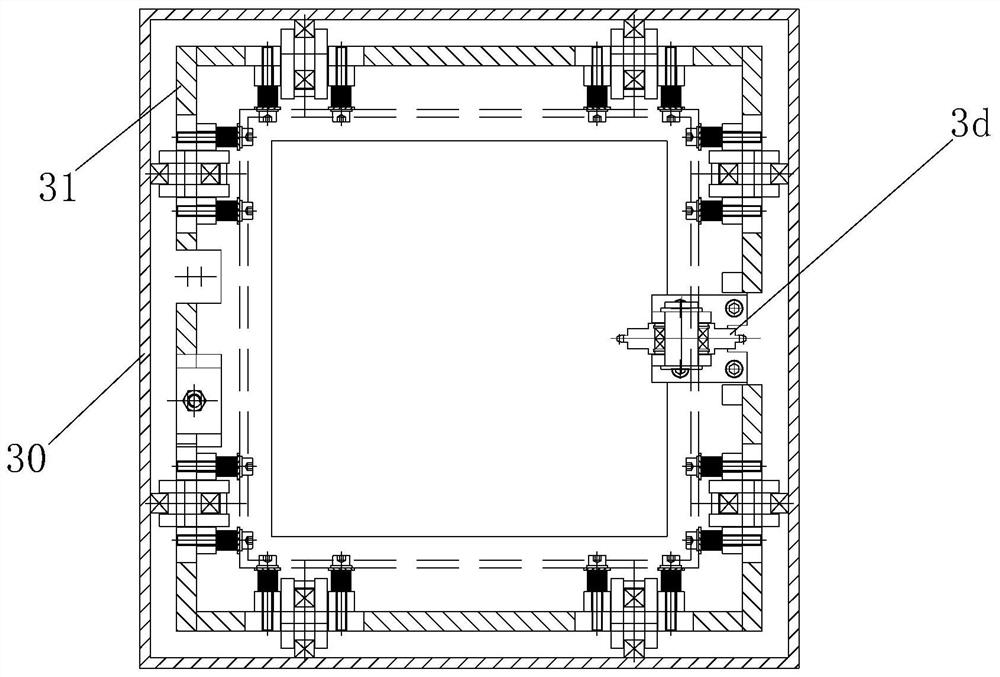

[0031] Such as figure 1 , figure 2 As shown, its basic structure includes a fixed arm, a telescopic arm, a terminal arm, and a servo drive assembly for driving the aforementioned arms; the fixed arm, the telescopic arm and the terminal arm are sequentially socketed;

[0032] The fixed arm includes: a cylindrical fixed arm body 30 with an open lower end, and a fixed arm support kit arranged at the lower end of the arm body 30;

[0033] The fixed arm is a basic support and connection structure. In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com