Stepped shaft wheel train structure for increasing force transmission strength

A stepped shaft and stepped technology, applied in the field of stepped shaft gear train structure, can solve the problems of increased labor intensity and cost, insufficient transmission torque between shafts and wheels, smaller shaft diameter, etc., to achieve low cost, increased transmission torque efficiency, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

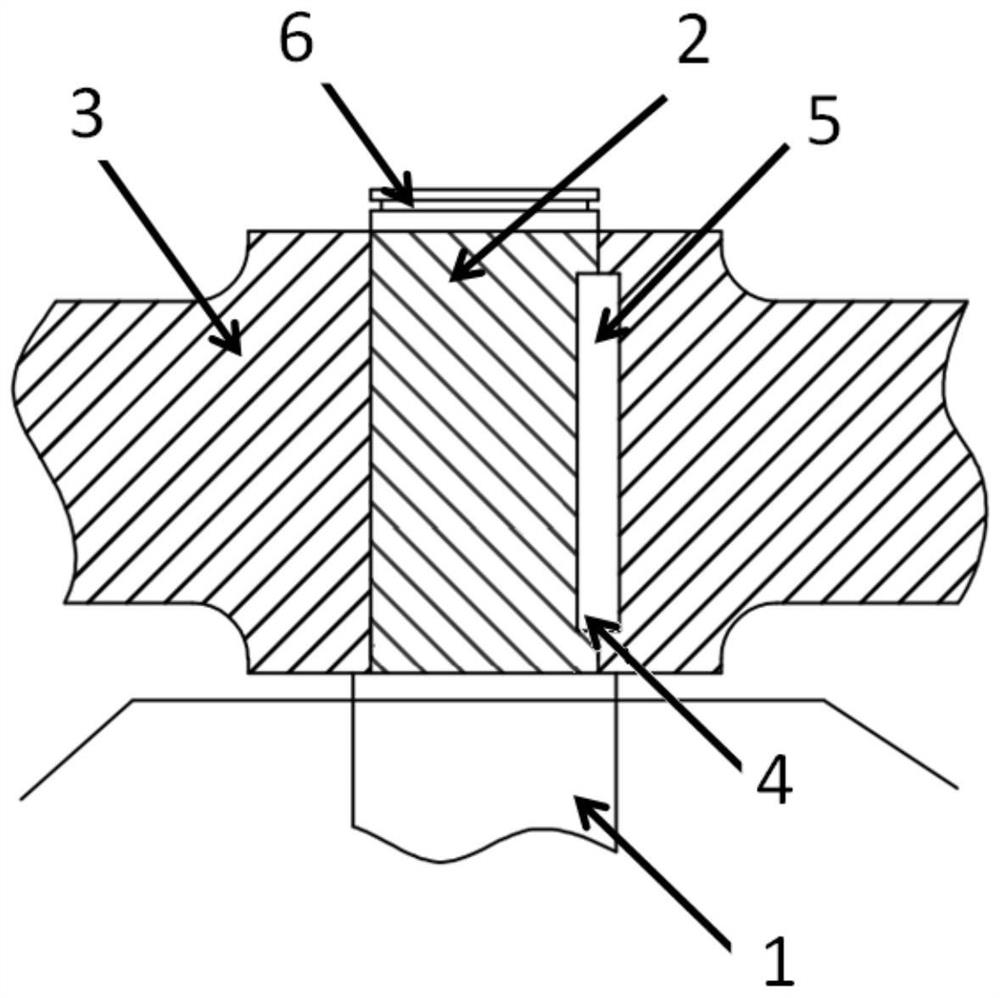

[0016]This example is an example of the rotation wheat scallion axle structure, such asfigure 1 In the original structure, the stepped axis 1 diameter is 70mm, the step two axis 2 is 65mm, the step two axis 2 length is 120 mm, the wheel 3 is fitted on the step two shaft 2, often appears to be a step axis 1 and the step two-axis 2 connection Fatigue breaks.

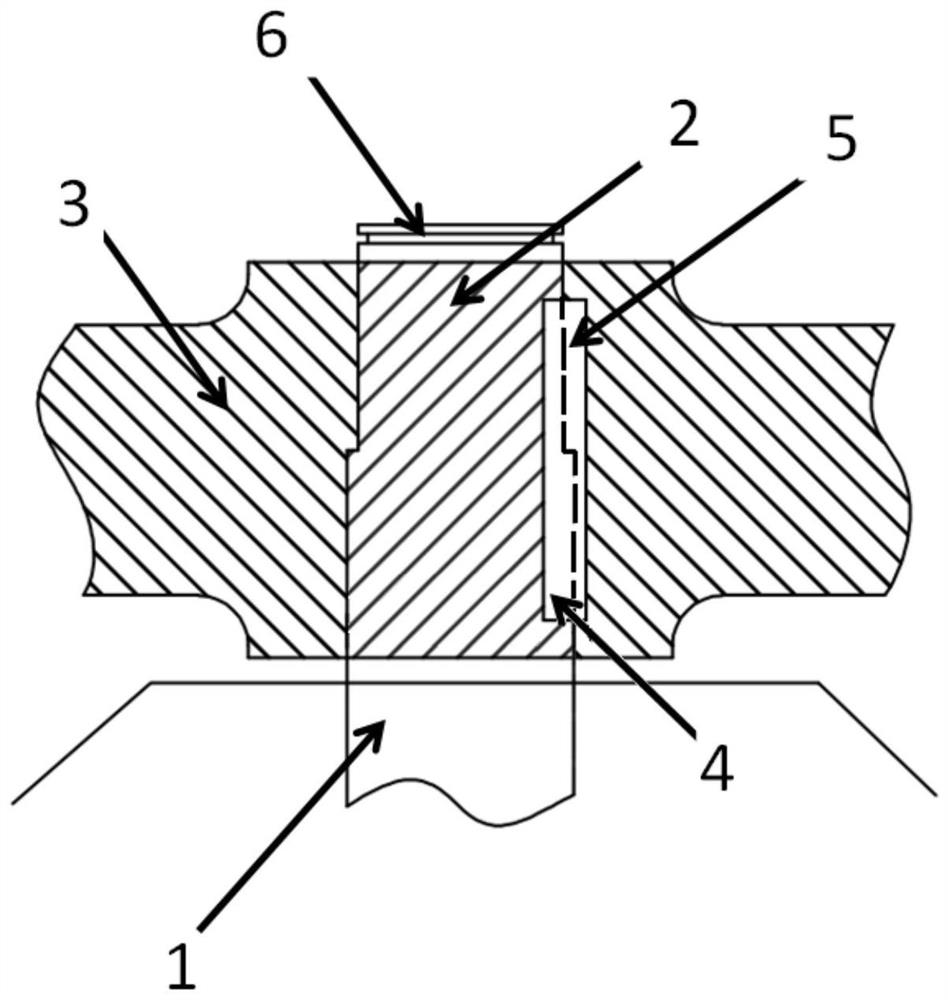

[0017]In this embodiment, a step-axis wheel structure of an increased force transfer strength does not change the diameter of the original shaft, including the step axis inserted into the inner hole and the keyway opening in the step axis and the inner hole, said The step axis is composed of a step-shaped axis 1 having a diameter of 70 mm and a step two-axis 2 having a diameter of 65 mm, and the connection is located in the inner hole of the wheel 3, the inner hole of the wheel 3 is a step of forming the shape size and a step axis outer diameter. Hole, the step bore is composed of a step-axis hole 7 with a step two-axis hole 8, and...

Embodiment 2

[0019]In the step axle gear structure of the increasing force transfer intensity described in this embodiment, each of the structures and connection relationships are the same as in Example 1, and different points are: the stepped axis 7 and the step two-axis hole. The ratio of the length of 3: 7; the stepped axis 1 has a diameter of 10 mm, and the diameter of the step two shaft 2 is 9 mm.

Embodiment 3

[0021]In the step axle gear structure of the increasing force transfer intensity described in this embodiment, each of the structures and connection relationships are the same as in Example 1, and different points are: the stepped axis 7 and the step two-axis hole. The ratio of the length of 7: 3; the stepped axis 1 is 600 mm, and the diameter of the step two shaft 2 is 550 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shaft diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com