Oil returning and dripping system of rotary fan

A technology of rotary fan and oil system, which is applied in mechanical equipment, engine components, machines/engines, etc. It can solve the problems of unstable flow rate, reduce the lubrication and cooling effect of the main engine inner wall, and accelerate the consumption of lubricating oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

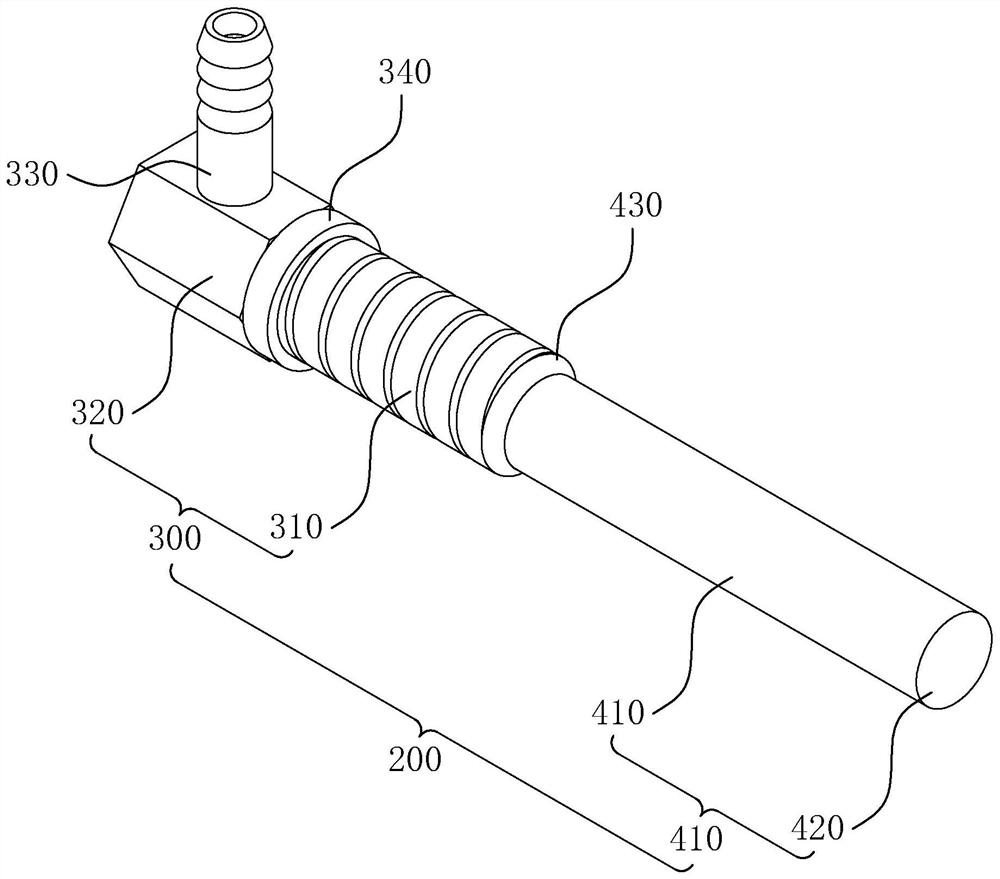

[0042] The following is attached Figure 1-10 The application is described in further detail.

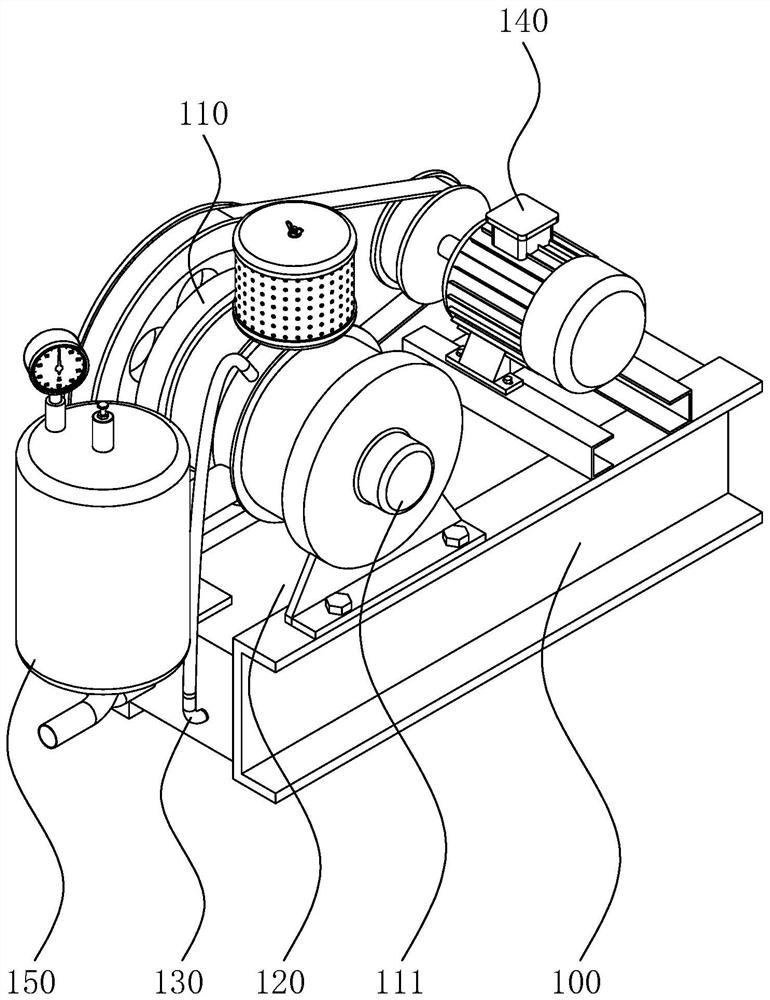

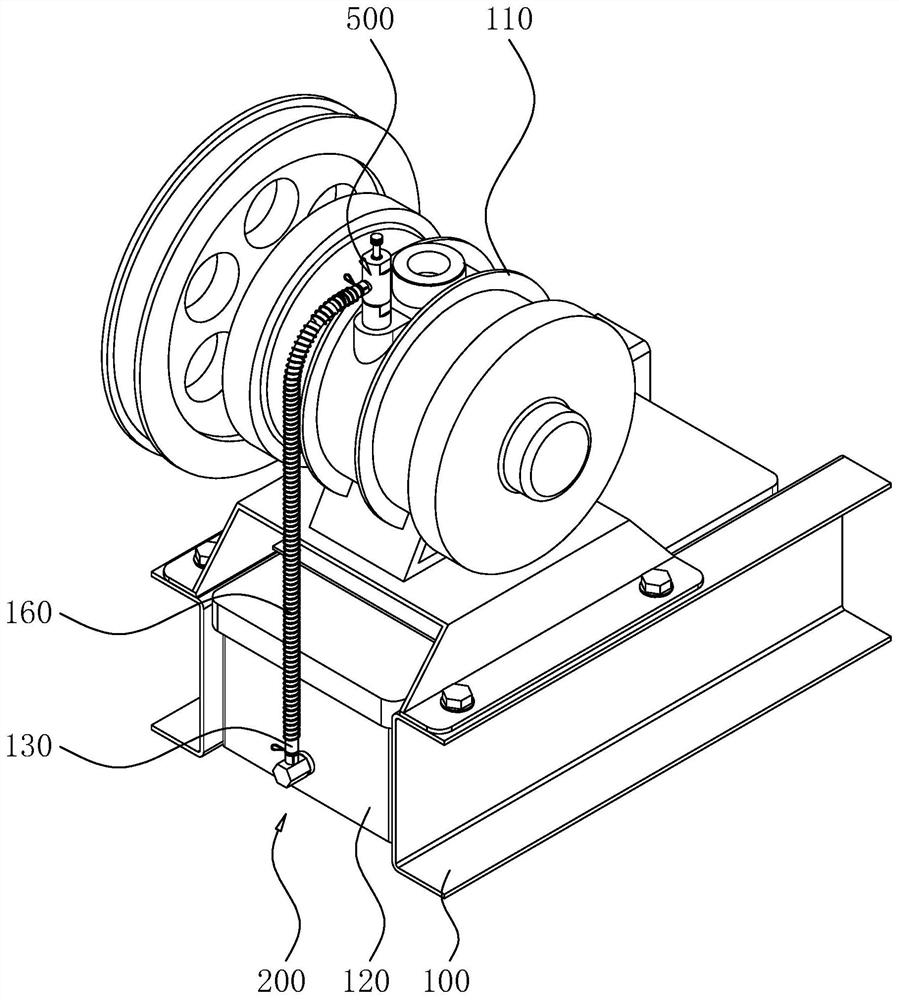

[0043] refer to figure 1 , in the related art, the rotary fan includes a base 100, on which a main engine 110 is fixedly connected by bolts, and a rotor 111 for compressing air is rotatably connected in the main engine 110. The host 110 is provided with an air inlet and an air outlet, and the air in the atmosphere enters the host 110 through the inlet and exits the host 110 through the outlet. A drive motor 140 is also fixedly connected to the base 100 by bolts, and the drive motor 140 is connected to the rotor 111 through a belt. An oil tank 120 is fixedly connected to the base 100 by bolts, and lubricating oil is stored in the oil tank 120 , and the oil tank 120 communicates with the air intake end of the main engine 110 through an oil return pipe 130 .

[0044] When the rotary fan starts, air enters the main engine 110 from the air inlet of the main engine 110, and the lubrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com