Air suction silencer for reciprocating piston type compressor

A technology of reciprocating pistons and compressors, used in machines/engines, liquid variable-capacity machinery, mechanical equipment, etc., can solve the problems of low suction mass flow, low refrigerant gas density, and low compressor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

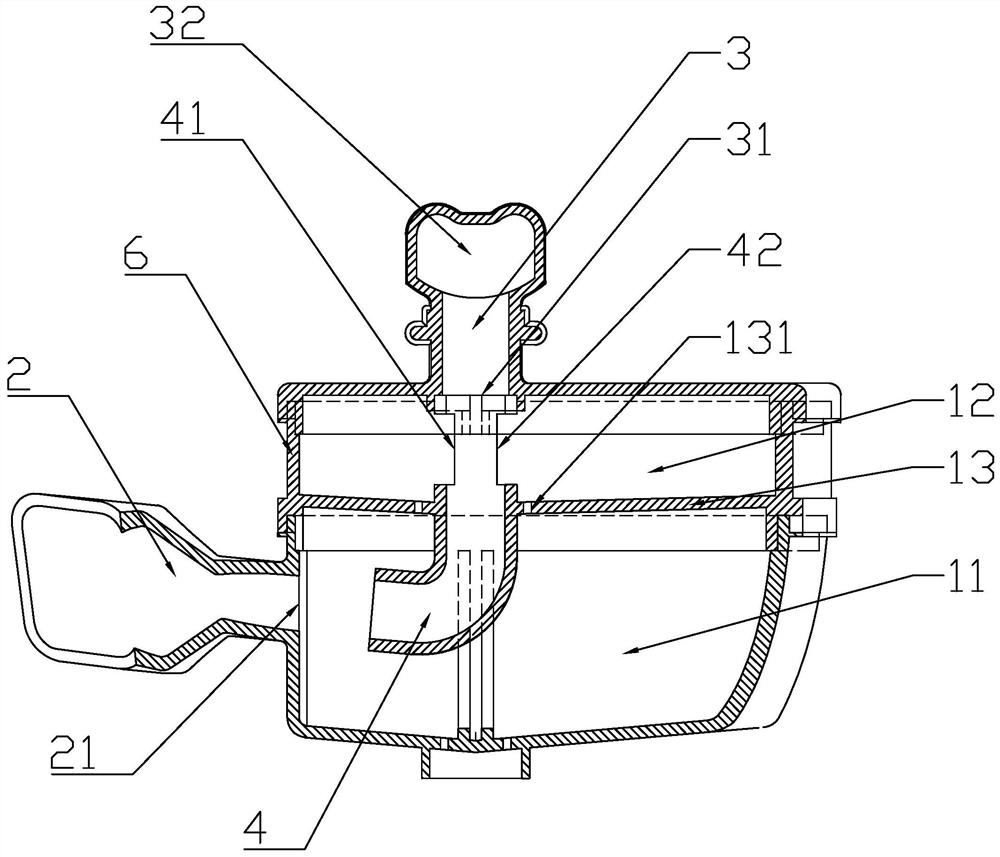

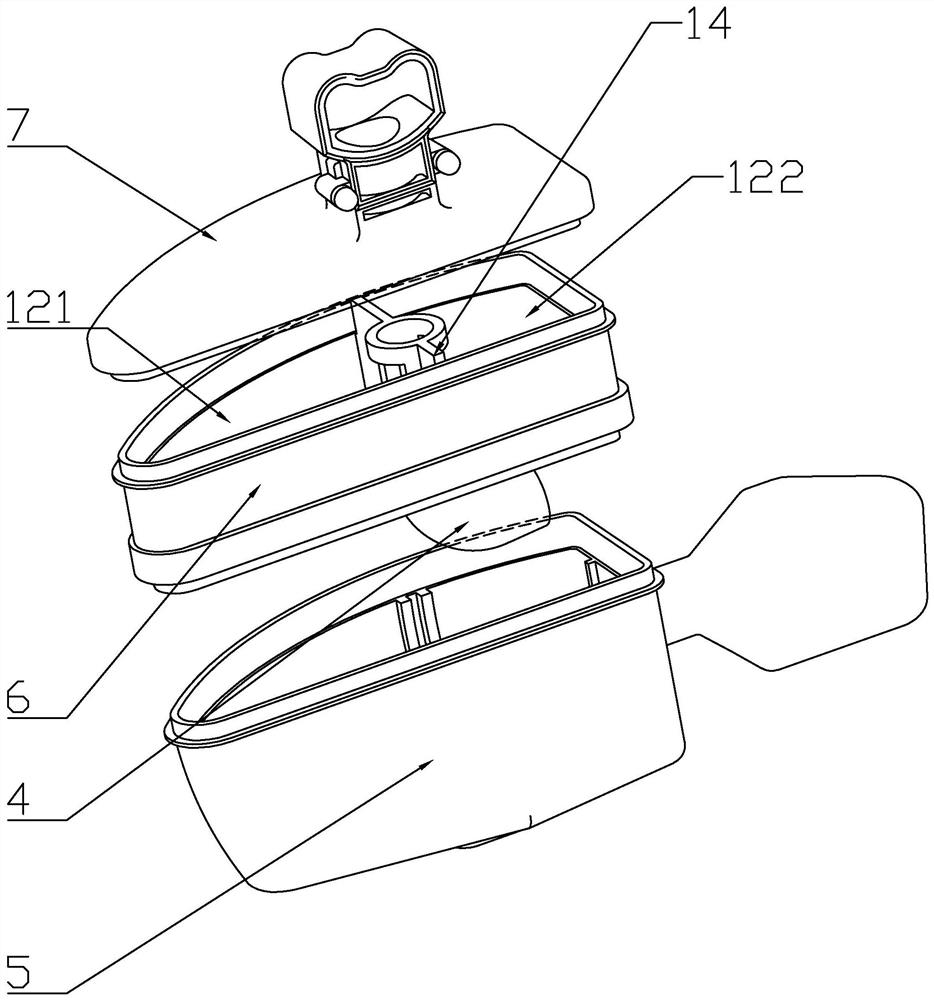

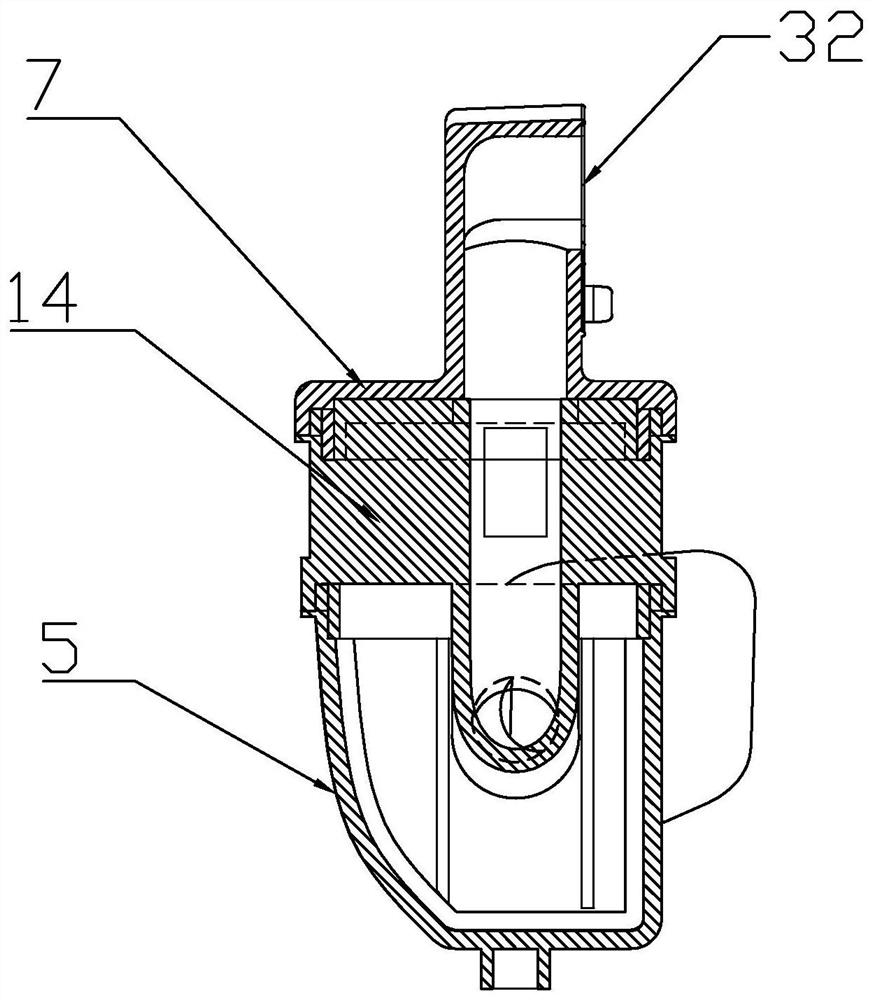

[0030] like figure 1 , figure 2 , image 3 In the shown embodiment, a suction muffler for a reciprocating piston compressor includes a lower case 5, a side wall 6, an upper cover 7 and an inner insertion pipe 4, and the lower case 5, the side wall 6 and the upper cover 7 are The cover is enclosed to form a sound-absorbing chamber. One side of the lower box 5 is provided with an air inlet pipe 2, and the connection between the air inlet pipe 2 and the lower box 5 forms an air inlet 21, the diameter of the air inlet 21 is 7mm, and the side wall 6 is inserted above the lower box 5, and the upper side wall 6 is inserted with a The upper cover 7 is provided with an air outlet pipe 3 on the top of the upper cover 7 , and an air outlet 31 is formed at the joint between the air outlet pipe and the upper cover 7 . The inner side of the side wall 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Opening area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com