Mud-resistant polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of anti-mud polycarboxylate water reducing agent and its preparation field, can solve the problem that the polycarboxylate water reducing agent is easily adsorbed by the surface of soil particles and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

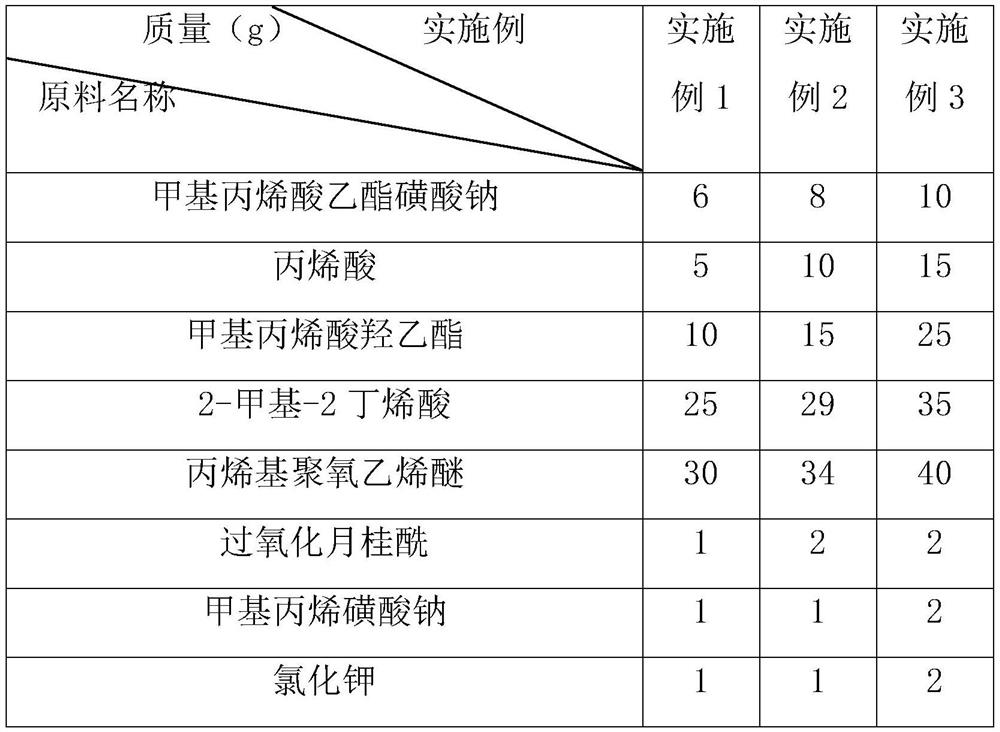

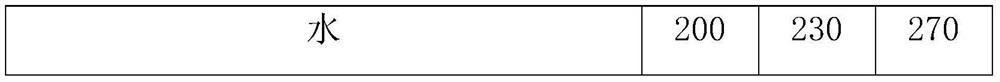

Embodiment 1-6

[0033] The following is illustrated by taking Example 1 as an example, a preparation method of mud-resistant polycarboxylate superplasticizer, comprising the following steps:

[0034] Solution preparation: dissolving propylene polyoxyethylene ether and lauroyl peroxide in 70ml water to form aqueous solution A; dissolving sodium methacrylate in 5ml water to form aqueous solution B; acrylic acid, hydroxyethyl methacrylate, 2-methyl -2 Butenoic acid and sodium ethyl methacrylate sulfonate were dissolved in 120ml of water to form aqueous solution C; potassium chloride was dissolved in 5ml of water to form aqueous solution D.

[0035] Heating reaction: Put the aqueous solution A into the reaction container, heat and stir until the temperature is 60°C, then add the aqueous solution B dropwise to the aqueous solution A first, and then add the aqueous solution C dropwise after the aqueous solution B is added dropwise, within 1 hour, mix the aqueous solution B and After the aqueous sol...

Embodiment 7-10

[0044] As shown in Table 3, compared with Example 2, the main difference between the mud-resistant polycarboxylate superplasticizers of Examples 7-10 lies in the different reaction temperature and time during the preparation of the superplasticizer.

[0045] Preparation process parameter table in each embodiment of table 3

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com