Axial-flow type double-duct water-jet propeller

A water jet propulsion, axial flow technology, applied in fluid mechanical engineering, ship propulsion field, can solve the problems of large space size, multi-stage water jet propulsion weight, low head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

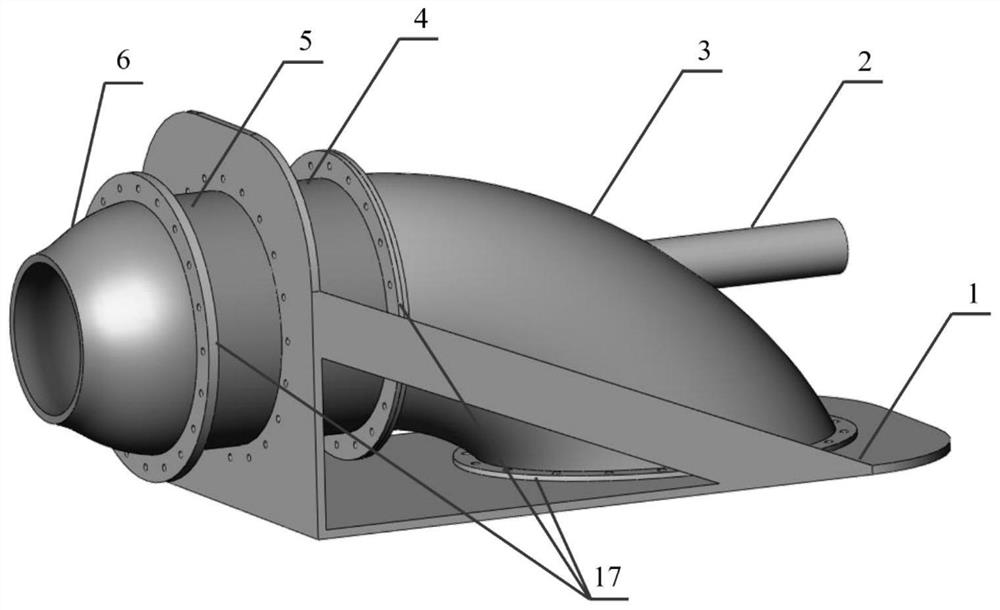

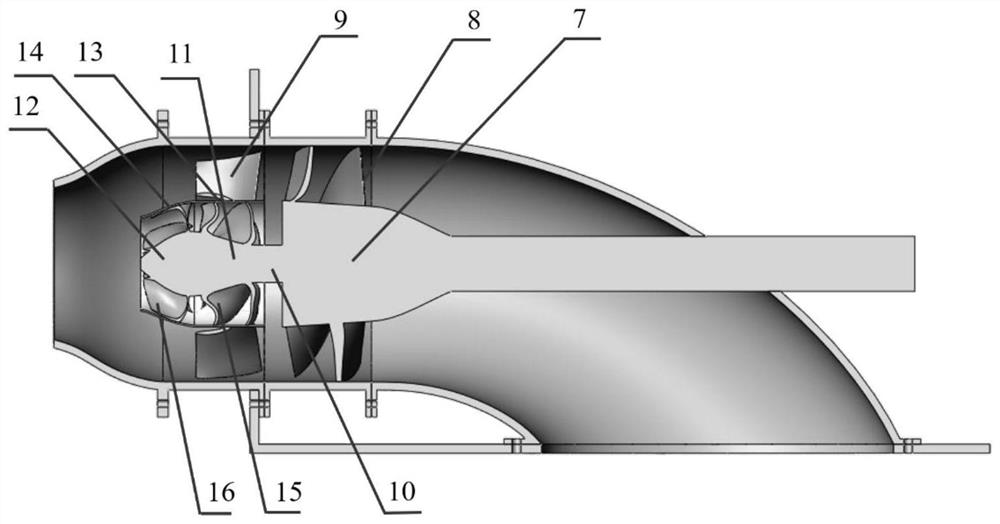

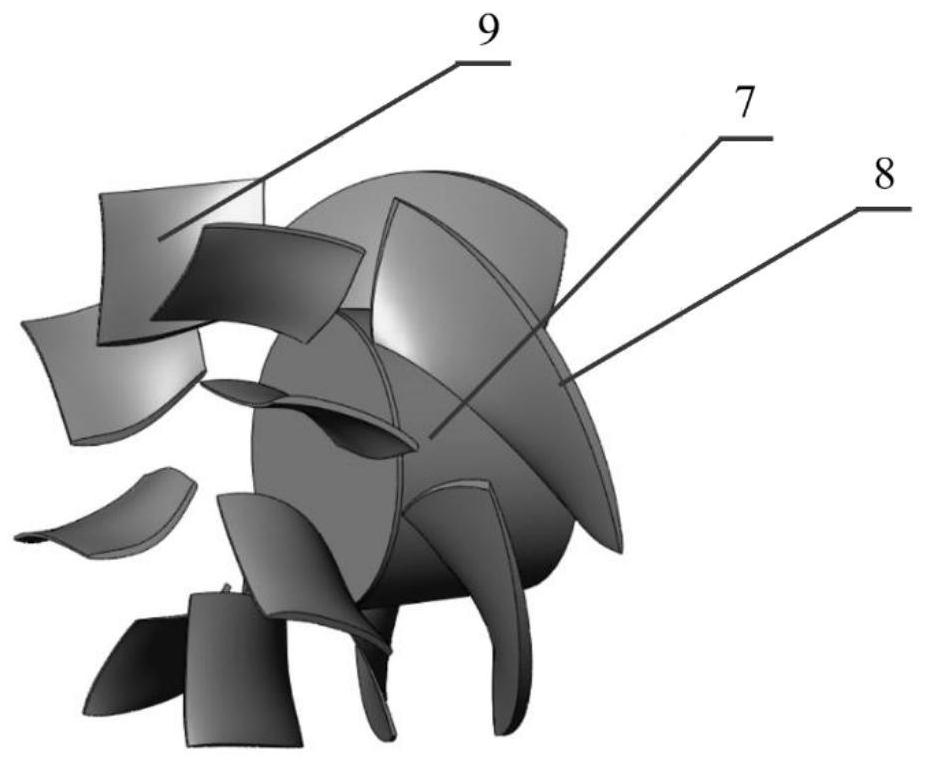

[0047] Such as figure 1 , 2 As shown, a new axial-flow double-duct water jet propeller consists of a bracket 1, an outer duct drive shaft 2, a water inlet channel 3, an outer duct impeller chamber 4, an outer duct guide vane chamber 5, and a nozzle 6 , outer duct impeller hub 7, outer duct impeller blade 8, outer duct guide vane blade 9, inner duct drive shaft 10, inner duct impeller hub 11, inner duct guide vane hub 12, inner duct impeller chamber 13, inner duct The guide vane chamber 14, the inner channel impeller blade 15, the inner channel guide vane blade 16, and the flange 17 are composed.

[0048] The support 1 is installed in the ship, and the length, width and height of the support 1 are 2000mm, 600mm, and 800mm respectively, and the fillet radius is 150mm. The bottom is fixedly connected to the hull by bolts, and the vertical section of the bracket 1 is located between the impeller chamber 4 of the outer duct and the guide vane chamber 5 of the outer duct, which pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com