Semi-automatic hydraulic machine for bamboo fiber synthetic sleeper

A bamboo fiber, semi-automatic technology, applied in the field of hydraulic presses, can solve the problems of hydraulic presses without bamboo fiber synthetic sleepers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

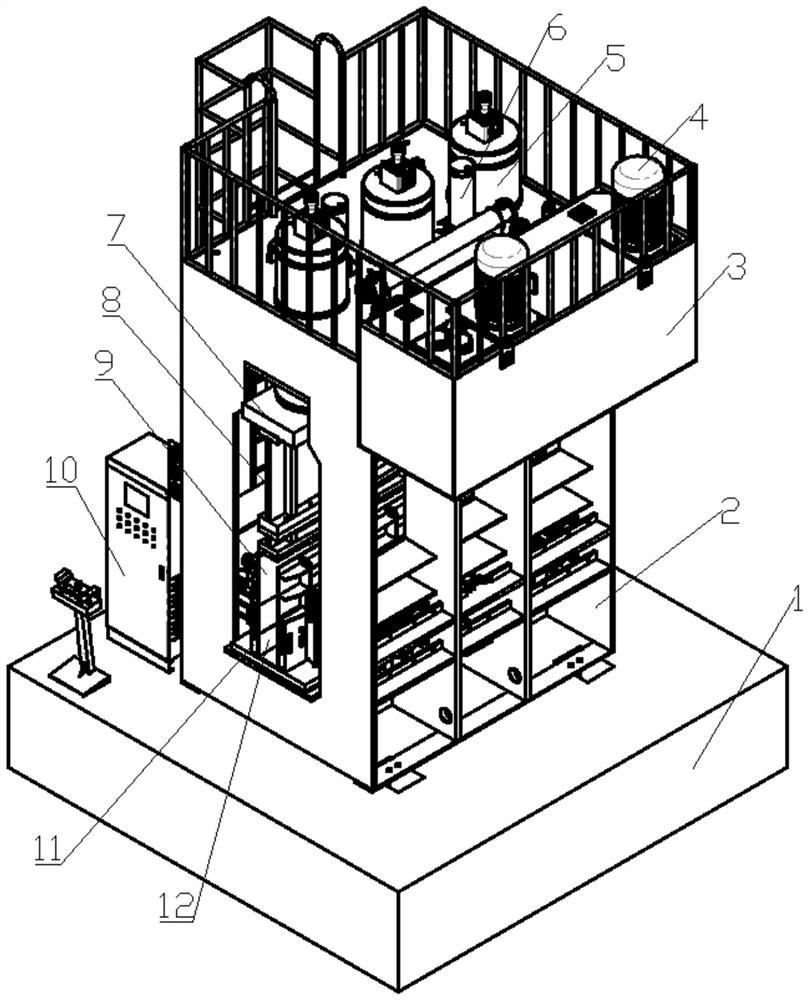

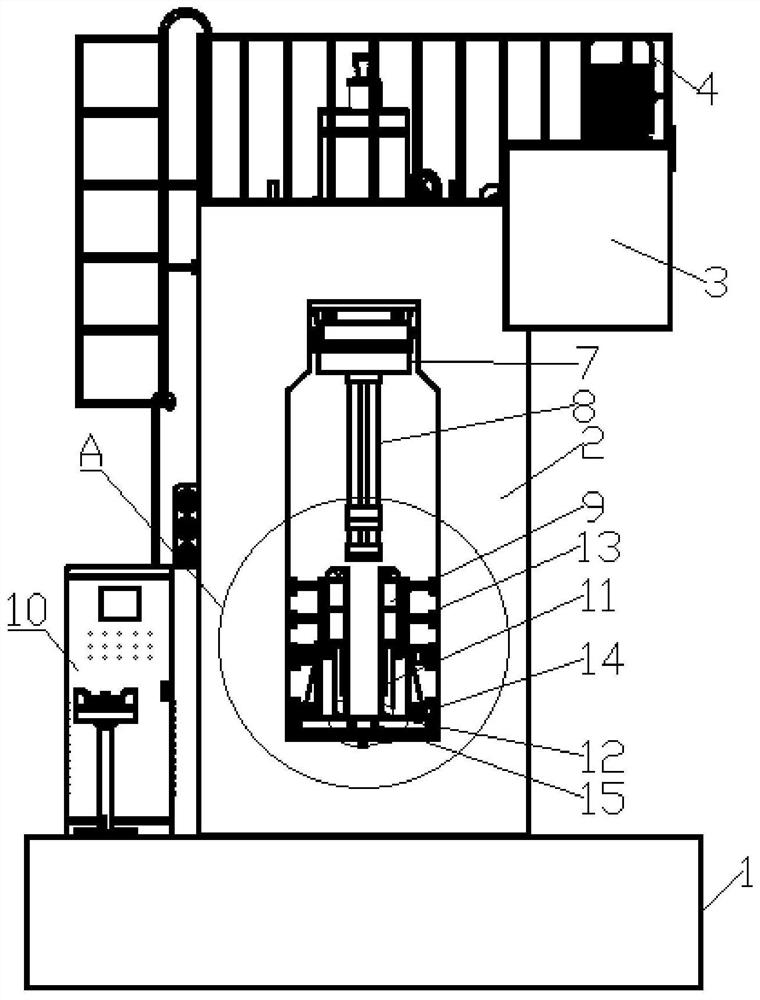

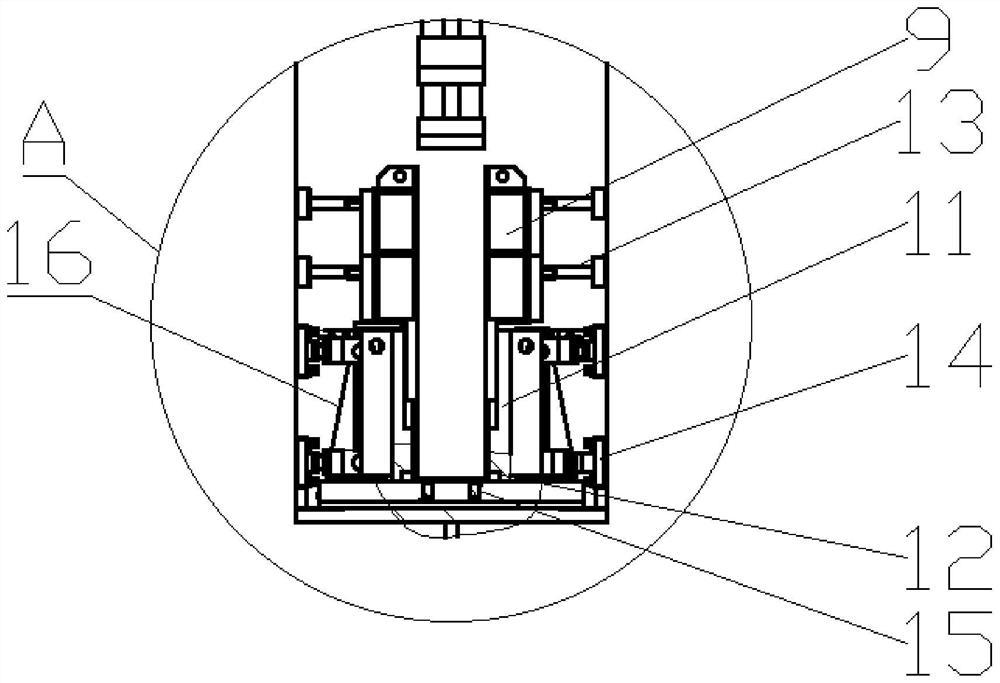

[0027] Present embodiment provides a kind of semi-automatic hydraulic machine of bamboo fiber synthetic sleeper, comprises the electric control box 10 and support frame 2 that are located on the foundation 1, and the bottom of described support frame 2 is provided with the mold 12 that is placed for pressing bamboo fiber synthetic sleeper Backing plate 19, the outside of the length direction of the mold 12 is vertically provided with a mold outer wall 11, and both sides of the length direction of the mold 12 are vertically clamped with a raw material outer wall 9, and the outer side of the raw material outer wall 9 is provided with There are fixtures that can be adjusted along the width direction of the mold 12, and the supporting frame 2 is provided with a supporting assembly supporting the outer wall 11 of the mold along the width direction of the mold 12 and a supporting structure supporting the outer wall 9 of the raw material, the supporting assembly and the supporting stru...

Embodiment 2

[0030] This embodiment has been further improved on the basis of Embodiment 1. Specifically, the support assembly includes a plurality of adjustment cylinders 14 evenly distributed on the outside of the mold outer wall 11, and the adjustment cylinders 14 are arranged along the width direction of the mold 12, so The output end of the adjustment oil cylinder 14 is vertically connected with the mold outer wall 11.

Embodiment 3

[0032] This embodiment is further improved on the basis of Embodiment 1, specifically, the support structure includes a plurality of adjusting screws 13 uniformly distributed on the raw material outer wall 9, and the adjusting screws 13 are arranged along the width direction of the mold 12, and the One end of the adjusting screw 13 is threadedly connected with the support frame 2, and the other end is rotatably connected with the raw material outer wall 9, and the adjusting screw 13 is provided with an adjusting nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com