Sodium-ion battery positive plate, preparation method thereof and sodium-ion battery

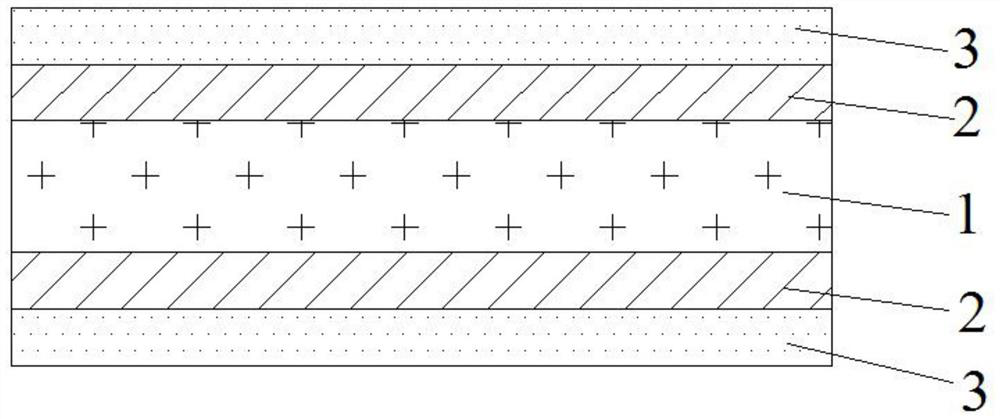

A sodium-ion battery and cathode sheet technology, applied in electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problems of affecting the contact of cathode materials, loose electrode structure, and residues, etc., to improve the volumetric energy density. , The effect of reducing the thickness of the battery and reducing the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a sodium ion battery, the preparation method of which is as follows:

[0031] 1) Preparation of positive electrode sheet:

[0032] After adding PVDF positive electrode binder into N-methylpyrrolidone (NMP) solvent to make a glue, add acetylene black positive electrode conductive agent, super-P positive electrode conductive agent, Na 3 V(PO4) 3 The positive electrode active material is uniformly dispersed to obtain the positive electrode slurry, and then the slurry is evenly coated on the surface of the carbon-coated aluminum foil current collector with a coater, and dried; wherein, Na 3 V(PO4) 3 The mass ratio of :acetylene black:super-P:PVDF is 90:2.5:2.5:5.

[0033] Add PVDF adhesive to NMP solvent to make a glue, then add Na 2 C 2 o 2 N 2 Sodium supplement additive, evenly dispersed to get Na 2 C 2 o 2 N 2 Sodium additive slurry, followed by spreading Na 2 C 2 o 2 N 2 The sodium supplement additive slurry is uniformly coated on...

Embodiment 2

[0037] This embodiment provides a kind of sodium ion battery, and the difference from embodiment 1 is the preparation of positive electrode sheet:

[0038] After adding PVDF positive electrode binder into N-methylpyrrolidone (NMP) solvent to make a glue, add acetylene black positive electrode conductive agent, super-P positive electrode conductive agent, Na 3 V(PO4) 3 The positive electrode active material is uniformly dispersed to obtain the positive electrode slurry, and then the slurry is evenly coated on the surface of the carbon-coated aluminum foil current collector with a coater, and dried; wherein, Na 3 V(PO4) 3 The mass ratio of :acetylene black:super-P:PVDF is 90:2.5:2.5:5.

[0039] Add PVDF adhesive to NMP solvent to make a glue, then add Na 2 C 2 o 4 Sodium supplement additive, evenly dispersed to get Na 2 C 2 o 4 Sodium additive slurry, followed by spreading Na 2 C 2 o 4 The sodium supplement additive slurry is uniformly coated on the surface of the pos...

Embodiment 3

[0042] This embodiment provides a kind of sodium ion battery, and the difference from embodiment 1 is the preparation of positive electrode sheet:

[0043] After adding PVDF positive electrode binder into N-methylpyrrolidone (NMP) solvent to make a glue, add acetylene black positive electrode conductive agent, super-P positive electrode conductive agent, Na 3 V(PO4) 3 The positive electrode active material is uniformly dispersed to obtain the positive electrode slurry, and then the slurry is evenly coated on the surface of the carbon-coated aluminum foil current collector with a coater, and dried; wherein, Na 3 V(PO4) 3 The mass ratio of :acetylene black:super-P:PVDF is 90:2.5:2.5:5.

[0044] Add PVDF adhesive to NMP solvent to make a glue, then add Na 2 CO 3 Sodium supplement additive, evenly dispersed to get Na 2 CO 3 Sodium additive slurry, followed by spreading Na 2 CO 3 The sodium supplement additive slurry is uniformly coated on the surface of the positive pole p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com