Method for determining parallel development step pitch of inner and outer dumping sites of soft rock opencast coal mine

A technology for open-pit coal mines and determination methods, which is applied in earth-moving drilling, surface mining, underground mining and other directions, can solve the problems of lagging development of external dumping fields, increasing the mining cost of open-pit coal mines, and increasing transportation distances, so as to shorten the time of stripping and transportation. distance, reduce mining costs, and fully occupy the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

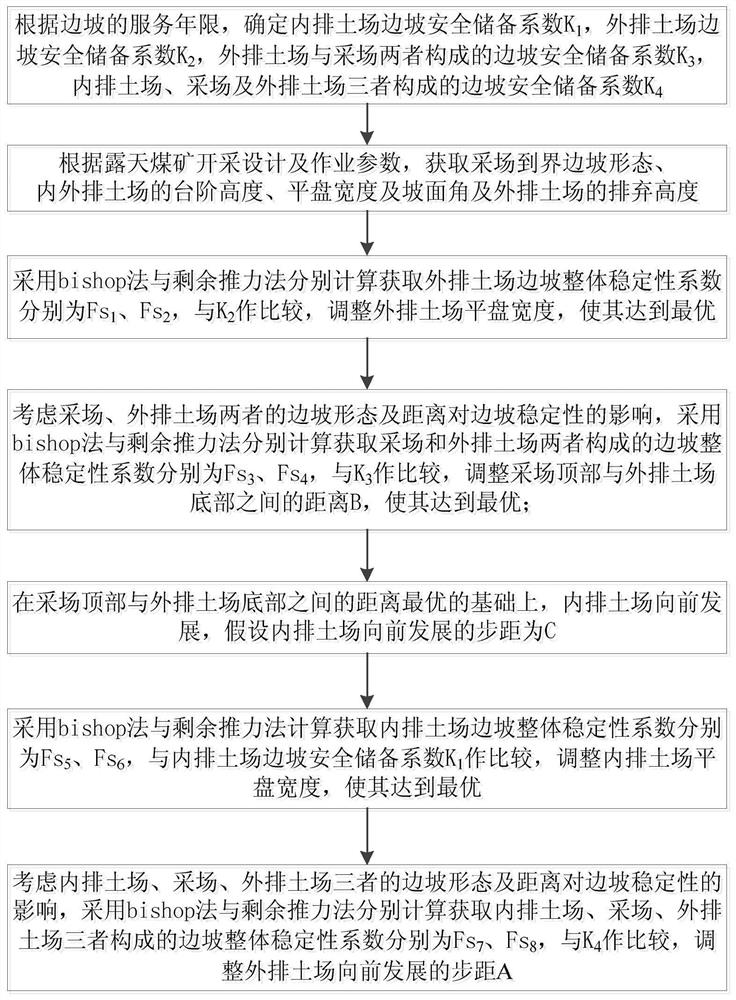

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

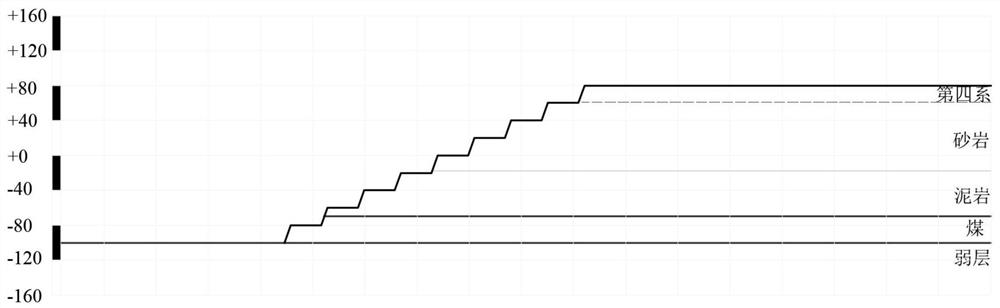

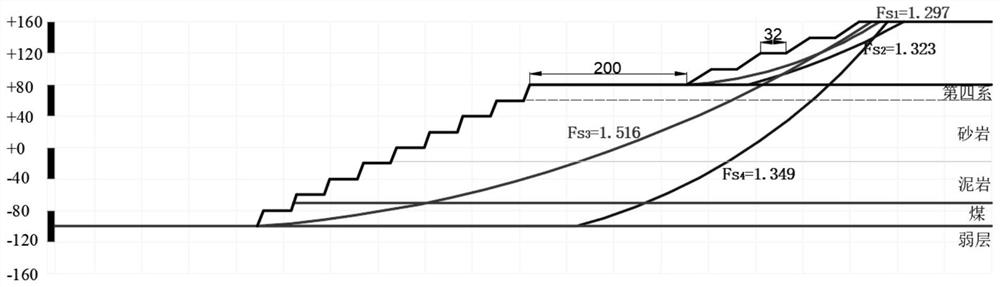

[0034]In this embodiment, an open-pit coal mining area is taken as an example. The lithology of the mining area is from bottom to top: coal seam, mudstone layer, sandstone layer and Quaternary clay layer. The Quaternary system is distributed in the whole area, the lithology is mainly clay, the strength of the mudstone layer is relatively soft, the main mining coal seam is 3 coal, the average thickness is 30m, 3 coal occurs in weak interlayers, and the mineral composition is mainly illite and montmorillonite , with the characteristics of severe water softening. The surface elevation of the open-pit coal mine is about +80 level, the mining depth is 180m, the design elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com