Iron chisel supply unit and blast furnace taphole drilling device

A technology of supply unit and brazing, which is applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of time-consuming and labor-consuming labor, limited brazing capacity, complicated operation, etc., and achieve the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

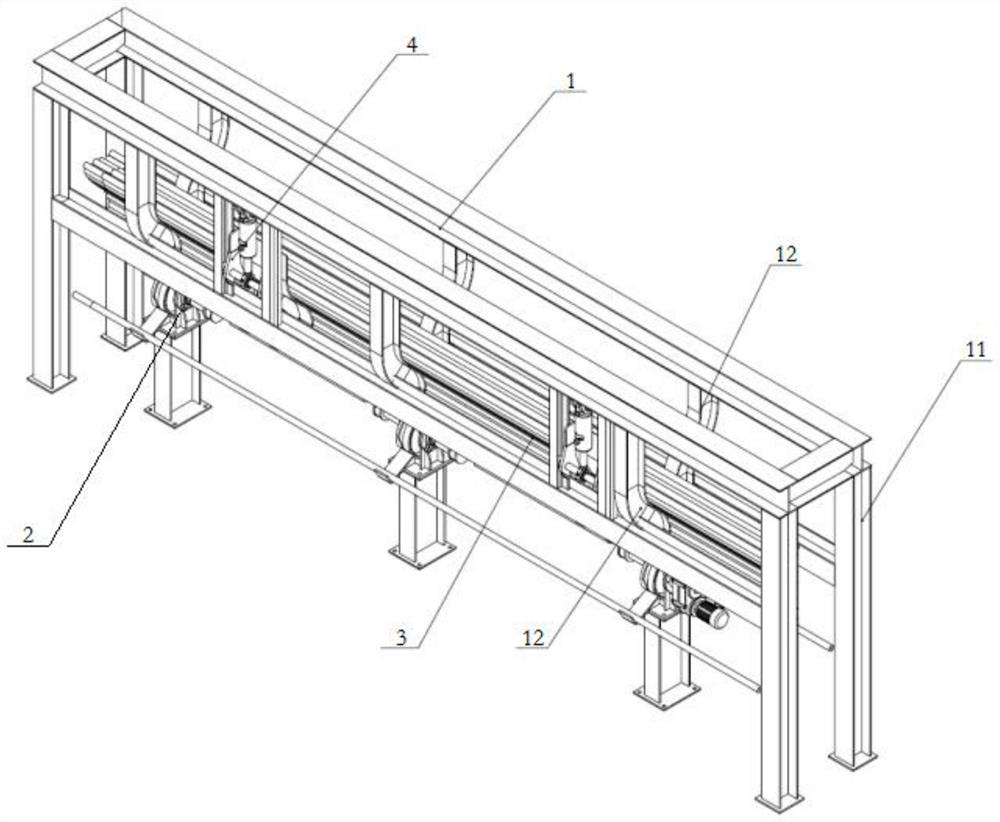

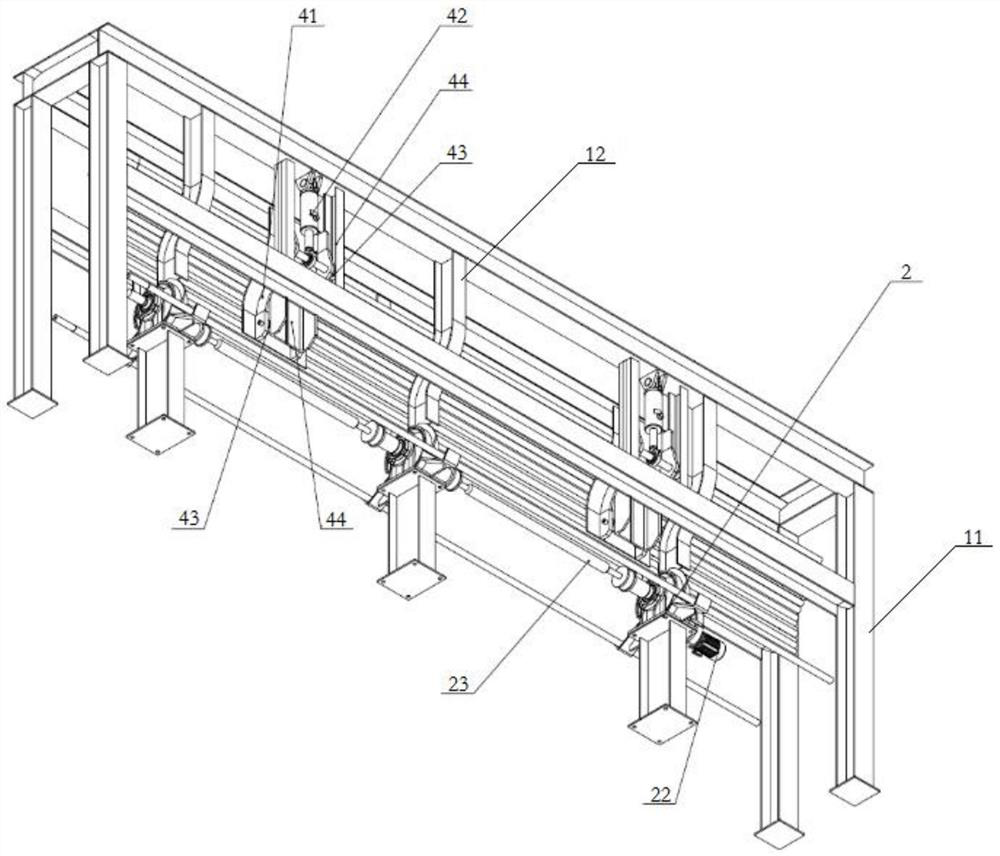

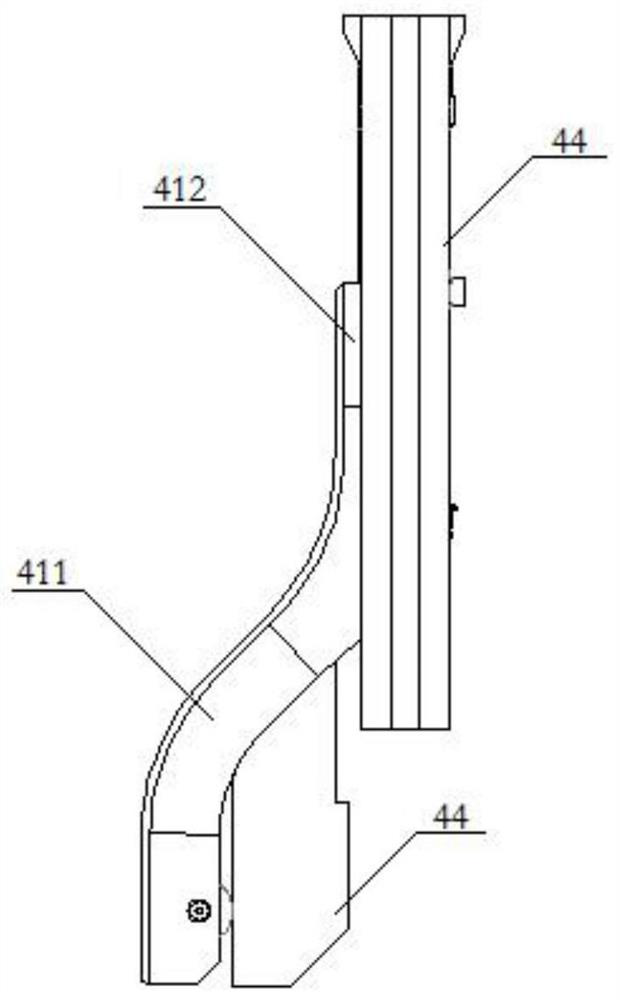

[0030] Such as figure 1 , figure 2 , Figure 5 and Figure 6 The embodiment of the present invention provides a brazing supply unit, including a brazing storage hopper 1 and a brazing retrieving mechanism 2. The brazing hopper 1 includes a material receiving tank with a wide top and a narrow bottom, and is connected to the bottom of the receiving tank. The blanking section at the end, the blanking section is provided with a blanking channel and the width of the blanking channel is less than twice the diameter of the iron drill, and the iron drill take-off mechanism 2 is arranged at the outlet end of the blanking channel .

[0031] The above-mentioned brazing storage hopper 1 is used to store a certain amount of brazing 3, and can supply the brazing 3 one by one to the brazing material taking mechanism 2; the top opening of the brazing storage hopper 1 is preferably capable of allowing a single bundle of brazing to enter , which is convenient for lifting equipment and the ...

Embodiment 2

[0049] An embodiment of the present invention provides a blast furnace taphole device, which includes a taphole machine, a braze supply unit, and a brazing replacement unit for installing the supplied braze on the taphole machine, and the braze supply unit The brazing supply unit provided in the first embodiment above is used.

[0050] The tapping machine is conventional equipment in this field, and its specific structure will not be repeated here.

[0051] The above-mentioned braze changing unit preferably adopts a braze changing manipulator, which clamps the iron braze 3 through the brazing tongs of the braze changing manipulator, which is an existing equipment in the art, and the specific structure will not be described in detail here; obviously, the braze changing The unit can clamp the iron chisel 3 from the iron chisel retrieving mechanism 2, and install the iron chisel 3 on the tap hole machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com