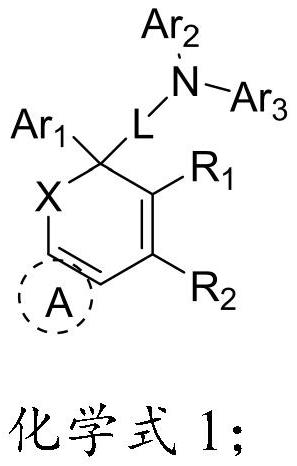

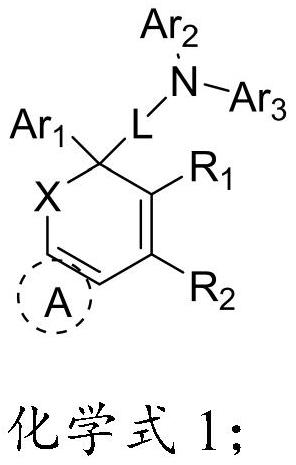

Organic electroluminescent compound, preparation method thereof and organic electroluminescent device containing organic electroluminescent compound

A luminescence and compound technology, which is applied in the field of luminescent materials, can solve problems such as unsatisfactory service life, and achieve the effects of not being easy to crystallize, reducing driving voltage, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

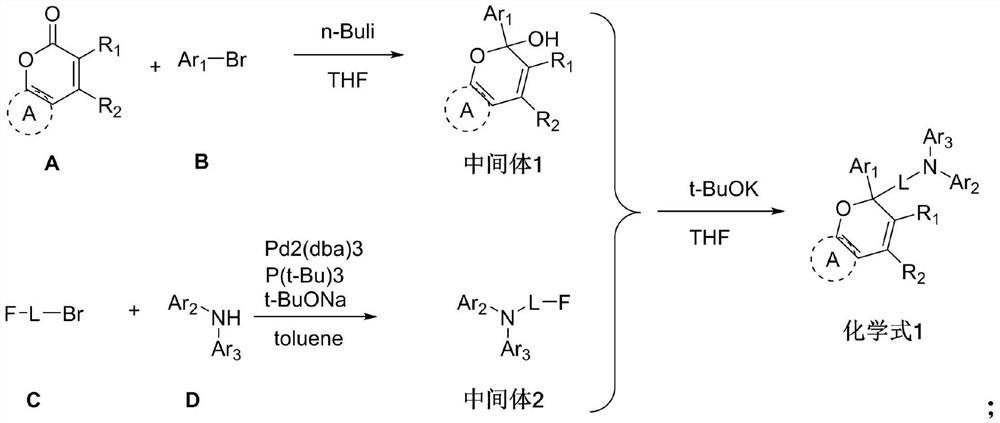

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: preparation compound HT-014

[0056]

[0057] (1) After adding the raw material B-014 (33.00mmol) and 50.00mLTHF into the reaction vessel, fully replace the air with nitrogen three times and lower the temperature to -78°C, and slowly add n-BuLi (33.00mmol) dropwise to the aforementioned mixture for reaction 2h, raw material A-014 (30.00mmol) was added, warmed up to room temperature, after stirring the mixture at room temperature for 5 hours, water was added and the mixture was extracted with dichloromethane. The extracted organic layer was then dried using sodium sulfate, and the solvent was removed using a rotary evaporator to obtain a solid organic. Use a small amount of dichloromethane to completely dissolve the solid organic matter, then slowly add it dropwise into the petroleum ether solution, stir evenly, and a precipitate is precipitated, and the solid is obtained by suction filtration, rinsed with absolute ethanol and petroleum ether in turn, an...

Embodiment 2

[0068] Embodiment 2: preparation compound HT-044

[0069]

[0070] (1) After adding the raw material B-044 (33.00mmol) and 50.00mLTHF into the reaction vessel, fully replace the air with nitrogen three times and lower the temperature to -78°C, and slowly add n-BuLi (33.00mmol) dropwise to the aforementioned mixture for reaction 2h, add raw material A-044 (30.00mmol), warm up to room temperature, stir the mixture at room temperature for 5 hours, add water and extract the mixture with dichloromethane; then use sodium sulfate to dry the extracted organic layer, and use a rotary evaporator Remove the solvent to obtain a solid organic matter; use a small amount of dichloromethane to completely dissolve the solid organic matter, and then slowly add it dropwise to the petroleum ether solution, stir evenly, and a precipitate is precipitated, and the solid is obtained by suction filtration, and then rinsed with absolute ethanol and petroleum ether. Wash and dry to obtain intermediat...

Embodiment 3

[0082] Embodiment 3: preparation compound H-052

[0083]

[0084] (1) After adding the raw material B-055 (33.00mmol) and 70.00mLTHF into the reaction vessel, fully replace the air with nitrogen three times and lower the temperature to -78°C, and slowly add n-BuLi (33.00mmol) dropwise to the aforementioned mixture for reaction 2h, add raw material A-055 (30.00mmol), warm to room temperature, stir the mixture at room temperature for 5 hours, add water and extract the mixture with dichloromethane; then use sodium sulfate to dry the extracted organic layer, and use a rotary evaporator Remove the solvent to obtain a solid organic matter; use a small amount of dichloromethane to completely dissolve the solid organic matter, and then slowly add it dropwise to the petroleum ether solution, stir evenly, and a precipitate is precipitated, and the solid is obtained by suction filtration, and then rinsed with absolute ethanol and petroleum ether. Wash and dry to obtain intermediate 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com