Equipartition and accompanying-pressing book case feeding device

A bookcase and booklet technology, which is applied in the direction of upper bookcase, book binding, printing, etc., can solve the problems of time-consuming and labor-consuming efficiency, skewed bookcase, and no operating mechanism, etc., to achieve high positioning accuracy and avoid offset Misalignment, reducing the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

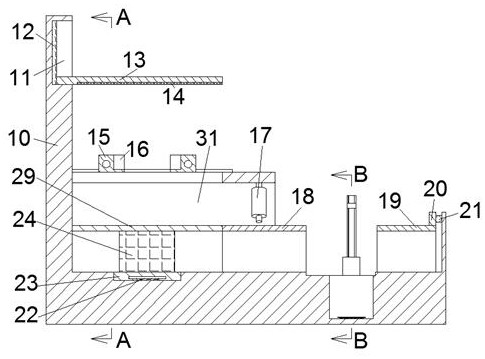

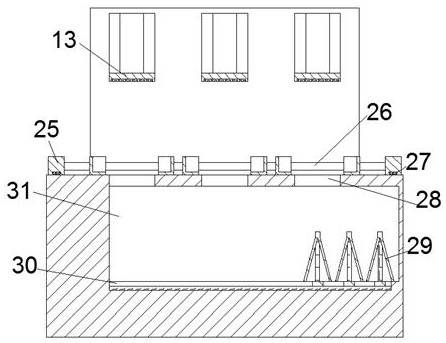

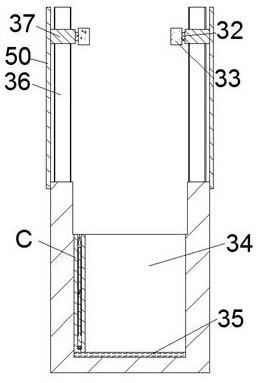

[0024] Combine below Figure 1-9 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0025] combined with Figure 1-9 The upper bookcase device for equalizing and accompanying pressing includes a box body 10, an equalizing component arranged at the right end of the box body 10, and an equalizing component that uses the telescopic rod length induction to control the pagination top block to evenly divide the booklets to avoid offset, and is arranged on the The pushing component on the right side of the equalizing component is used to push and transmit books, and the upper book case component is arranged on the left end of the box 10 to simultaneously perform multiple upper book case operations, and the books unfolded by the equalizing component are kept unfolded by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com